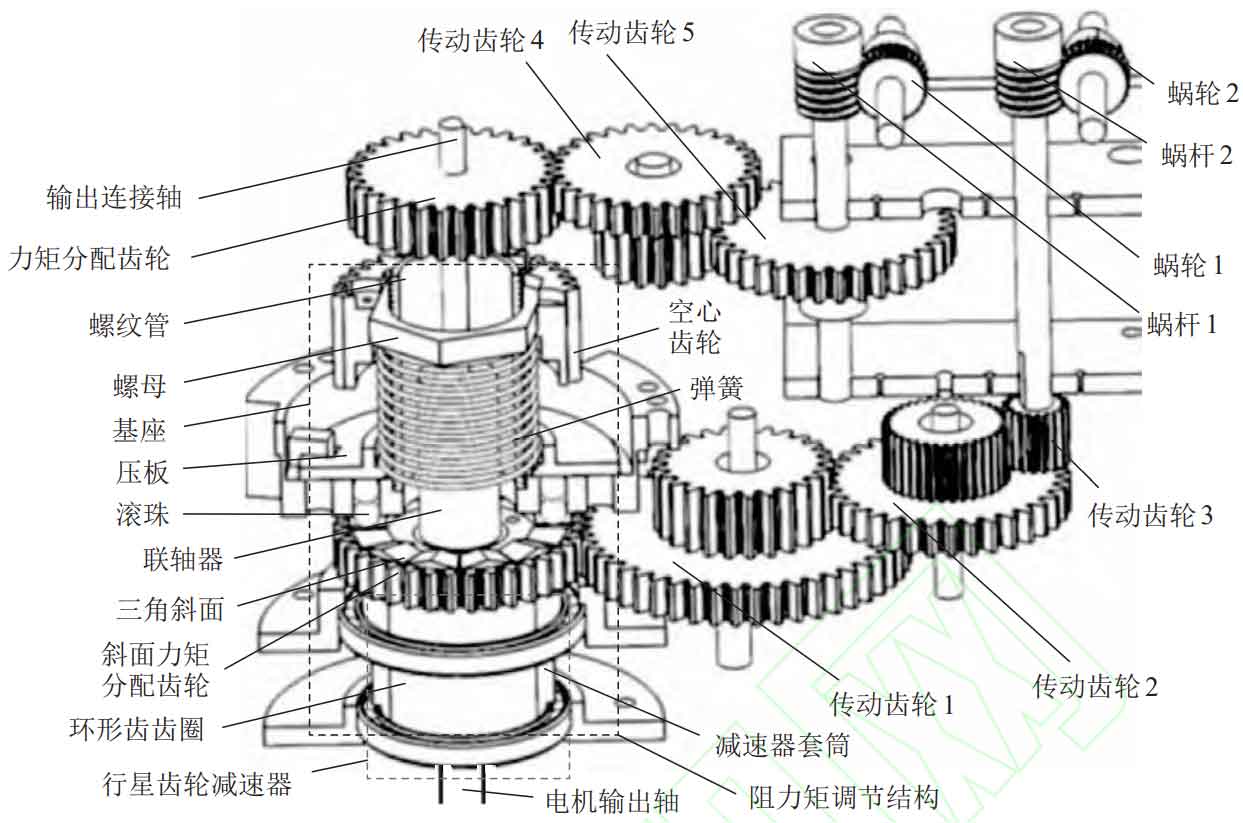

In general, the underactuated manipulator driven by motor usually uses the dynamic coupling effect to realize the underactuated form of the manipulator, while the planetary gear reducer is used to distribute two driving torques to achieve the underactuated form of the manipulator. Its transmission structure is shown in Figure 1.

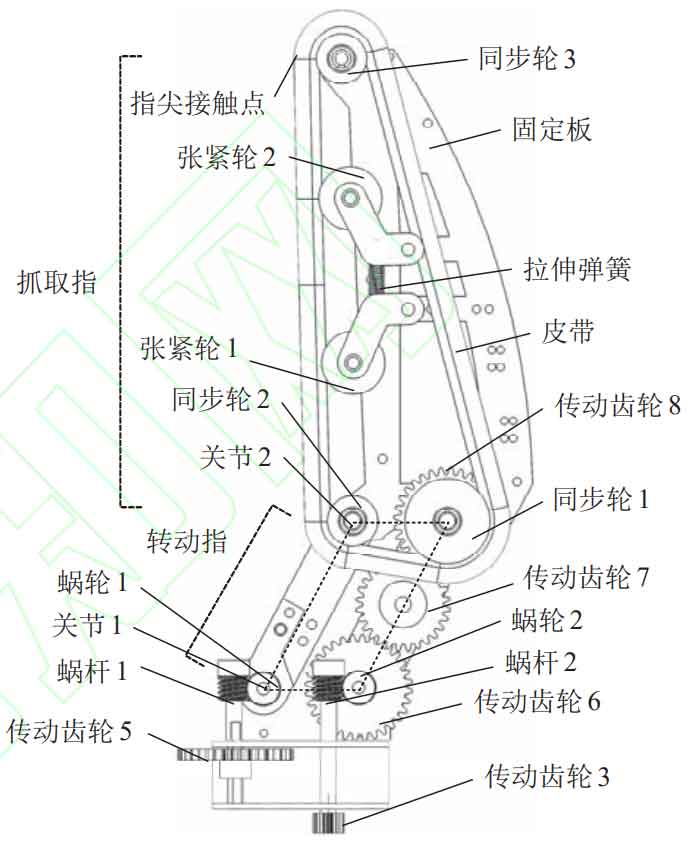

The transmission structure is mainly divided into two parts: torque regulating mechanism and gear transmission. It can be seen from Figure 1 that the internal gear ring and output connecting shaft of the planetary gear reducer are not fixed, so two mutually exclusive movements can be output. The output shaft is used as the first output, and the internal gear ring is used as the second output. The coupling fixes the output connecting shaft and the output shaft of the planetary gear reducer together, and transmits the power to the worm 1 and worm gear 1 through the torque distribution gear to realize the rotation of joint 1 in Figure 2; The bevel moment distribution gear and the inner gear ring of the planetary gear reducer are fixed, and the power is transmitted to the worm 2 and worm gear 2 to realize the rotation of the belt in Figure 2.

Taking advantage of the feature that the planetary gear structure can distribute two mutually exclusive movements, a resistance adjustment mechanism is embedded between the output shaft and the inner gear ring. Within a certain range, the force of the manipulator finger holding the target object can be adjusted indirectly by adjusting the resistance torque. The principle of the resistance torque adjustment mechanism is that the hollow gear rotates clockwise to drive the nut fixed on it to perform spiral movement on the threaded tube. The spiral movement forces the hollow gear to move downward, thereby compressing the spring, increasing the elastic force applied on the pressure plate. This elastic force will be applied on the triangular bevel of the bevel torque distribution gear through the ball rolling. The bevel moment distribution gear and the internal gear ring are relatively fixed. The resistance torque generated by the ball acting on the triangular bevel component will directly act on the internal gear ring, increasing the total resistance torque of the internal gear ring.

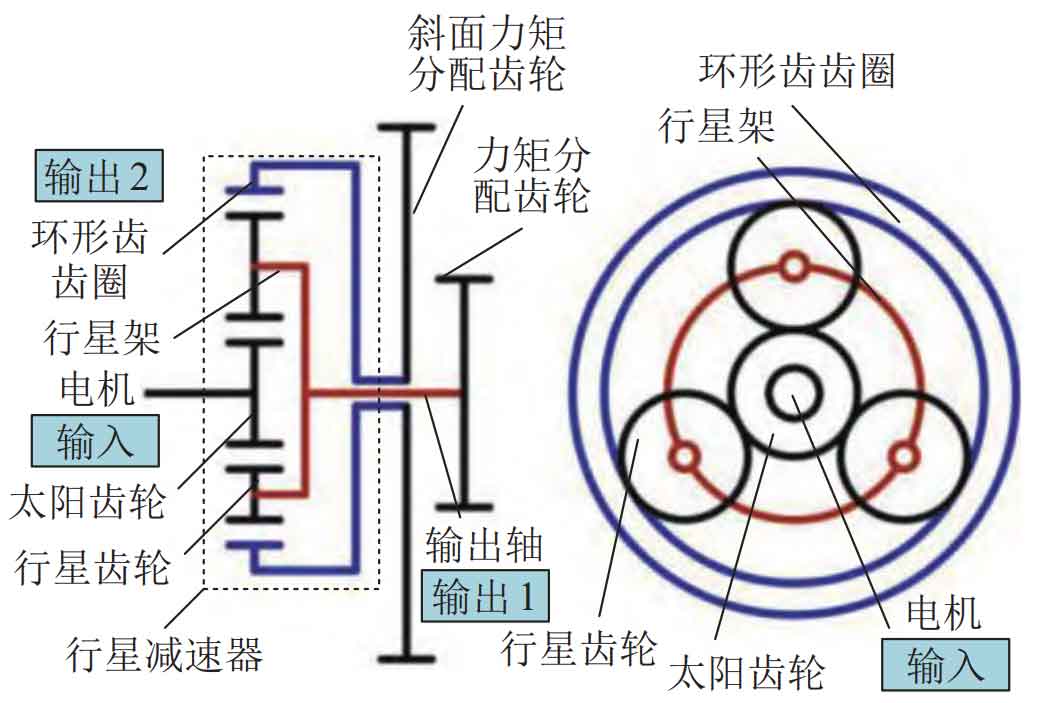

The transmission principle of the planetary gear mechanism and the connection diagram of the two torque distribution gears are shown in Figure 3. The bevel torque distribution gear and the internal gear ring are relatively fixed, and the torque distribution gear and the output shaft are relatively fixed. With a single motor input, the manipulator can output two motions, respectively controlling the closing of the manipulator finger and the rotation of the belt. In the process of grasping, the motor starts. Since the total resistance torque received by the internal gear ring is greater than that received by the output shaft, the output shaft makes the manipulator finger close until the target object is clamped by the transmission component. At this time, the total resistance torque received by the output shaft increases until it exceeds the resistance torque received by the internal gear ring. Then the internal gear ring drives the bevel torque distribution gear to rotate, and drives the belt to run and pull in the clamped target object.

The manipulator adopts this transmission system and finger structure, and utilizes the feature that the planetary gear structure can distribute two kinds of mutually exclusive motions, transferring the multi degree of freedom control from the finger end to the drive end, reducing the dynamic coupling effect in the finger motion. The designed resistance adjusting mechanism can indirectly adjust the force of the manipulator finger holding the target object within a certain range, thereby further reducing the number of sensors and reducing the complexity of motor control.

It is worth noting that the form of belt contact and belt pulling into the target object is adopted. On the one hand, the belt contact will not damage the object, so that the manipulator can grasp flexible target objects, such as paper cups, eggs, etc; On the other hand, after the manipulator fingers grasp the target object, it will pull in the object, and the synchronous pulley will rotate infinitely to avoid the motor stalling. Therefore, compared with other types of underactuated manipulators, the designed manipulator has better flexibility and stronger resistance to external shocks.