The main purpose of designing the precision forging blank of spiral bevel gear is to ensure that the metal can fill the forging die cavity smoothly during the precision forging of gear, so as to avoid the material waste caused by insufficient filling or flash of gear teeth. In the actual die forging production, how to minimize the forging allowance and obtain the near static forging after one-time forming is the first consideration of the designer. In order to obtain the ideal workpiece product, we need to consider not only the shape of the blank, but also the volume and other factors.

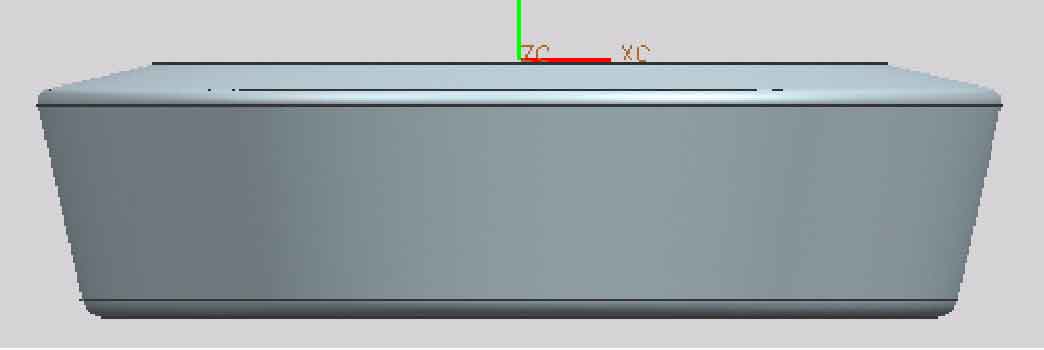

In addition, when designing the blank, the size of the blank in the height direction should also be ensured, which should generally be greater than the corresponding size of the spiral bevel gear precision forging. During the plastic forming of the driven spiral bevel gear, the flow path of the metal from the tooth end into the tooth cavity is a curve, with large resistance and long process. The metal flows into the tooth mold cavity along the outer diameter direction to form the spiral tooth mold body. This flow path of the metal filling the tooth cavity of the female mold determines the shape of the blank. In order to obtain the forging process with full tooth profile and small forming load, the precision forging blank of spiral gear is optimized in this paper, as shown in the figure below:

When designing forging stock, the following principles shall be observed:

(1) Generally, the height of spiral bevel gear blank should be greater than that of forging to ensure the metal flow in the forming process, mainly upsetting. So as to reduce friction resistance, forging deformation force and die wear.

(2) The fillet radius at the corner corresponding to the spiral bevel gear blank and the die shall be greater than the fillet radius at the corresponding forging to avoid folding.

(3) In each flow plane formed, the cross-sectional area of spiral bevel gear blank shall be equal to the sum of the cross-sectional areas of forging and flash.

The rough of spiral bevel gear shall be well lubricated during precision forging, and the lubricant shall meet the following requirements:

(1) The lubricant shall have good insulation performance to prevent the heat of the forging blank from being transferred to the die quickly, so as to avoid the rapid cooling of the forging blank and the rapid rise of the die temperature, resulting in the increase of deformation force and the reduction of the life of the die.

(2) It can effectively reduce the friction coefficient and wear of the die cavity between the deformed metal and the die cavity surface, which is conducive to filling the die cavity with the deformed metal and avoiding the rapid failure due to the out of tolerance of the die cavity size.

(3) Ensure the smooth demoulding of spiral bevel gear forgings and good surface finish of forgings. Less residue accumulation.

(4) Non toxic and harmless to human body. It shall be chemically stable during storage to facilitate mechanized spraying.