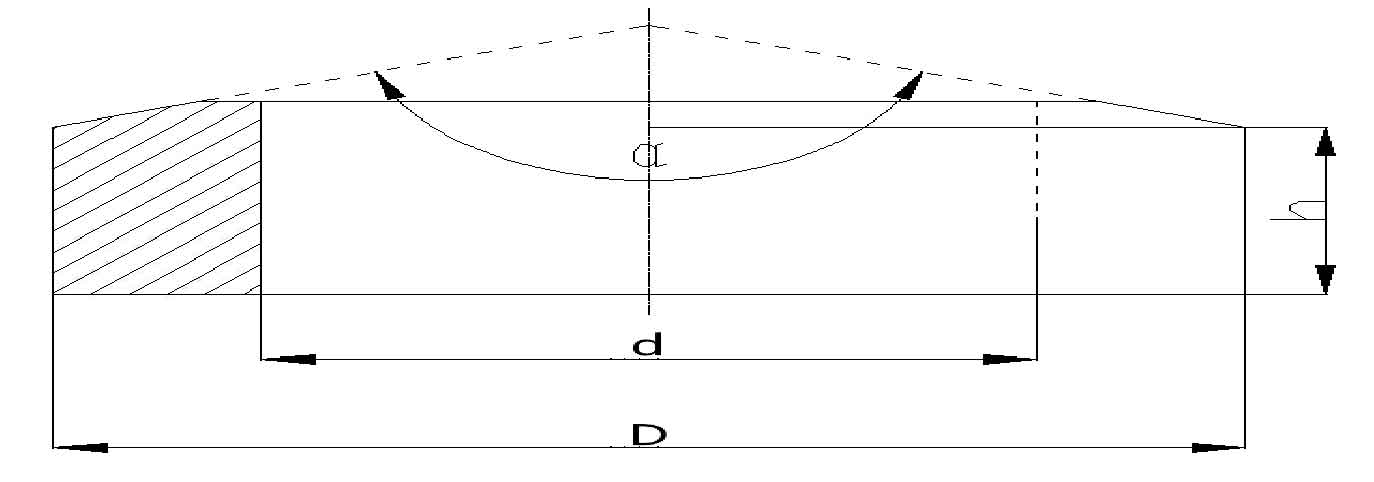

The shape of preform has a great influence on the cavity filling, material consumption and forming force of metal in the forming process. The spiral bevel gear studied in this paper is a conical part and adopts the double split extrusion scheme. Therefore, the preform structure is designed as a conical preform with cylindrical inner hole as shown in Figure 1.

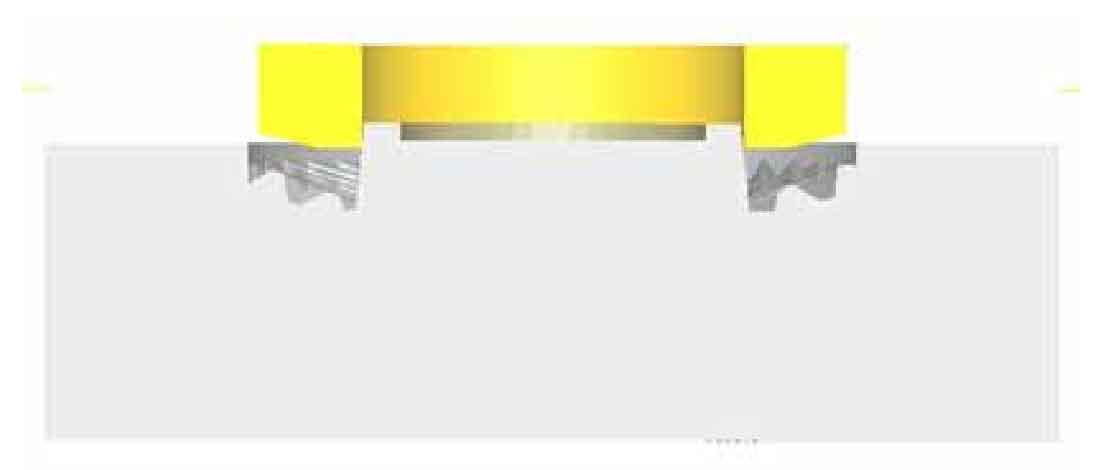

The selection of inner diameter D and outer diameter D of preform is closely related to the structure of female die and the size of formed parts. The preform outer diameter D is set as a fixed amount (166.5mm), and the inner diameter D is used as a variable for numerical simulation analysis. The selection of inner diameter D should be larger than the diameter of the small end of the concave die tooth shape. When the diameter of D is smaller than the diameter of the small end of the concave die tooth shape, the annular inner wall of the preform will be in direct contact with the lower ejector rod, as shown in Figure 2. When forming the spiral bevel gear in this state, the metal material first fills the small end of the concave die tooth shape. When the small end has been fully filled, too much metal material flows radially from the internal and external shunt gap, resulting in the failure to fill the large end of the concave die tooth shape in time, resulting in insufficient filling of the tooth shape.

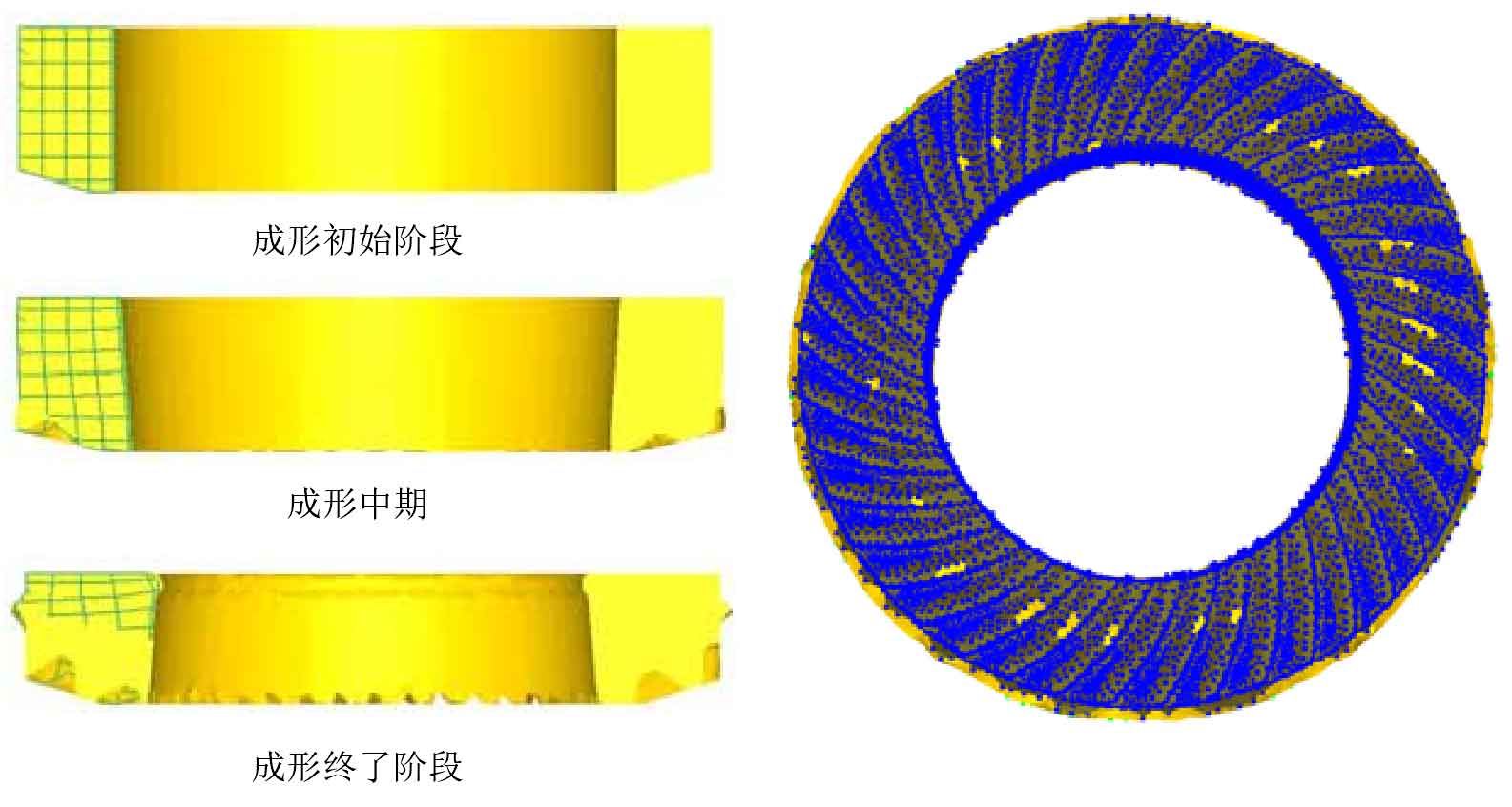

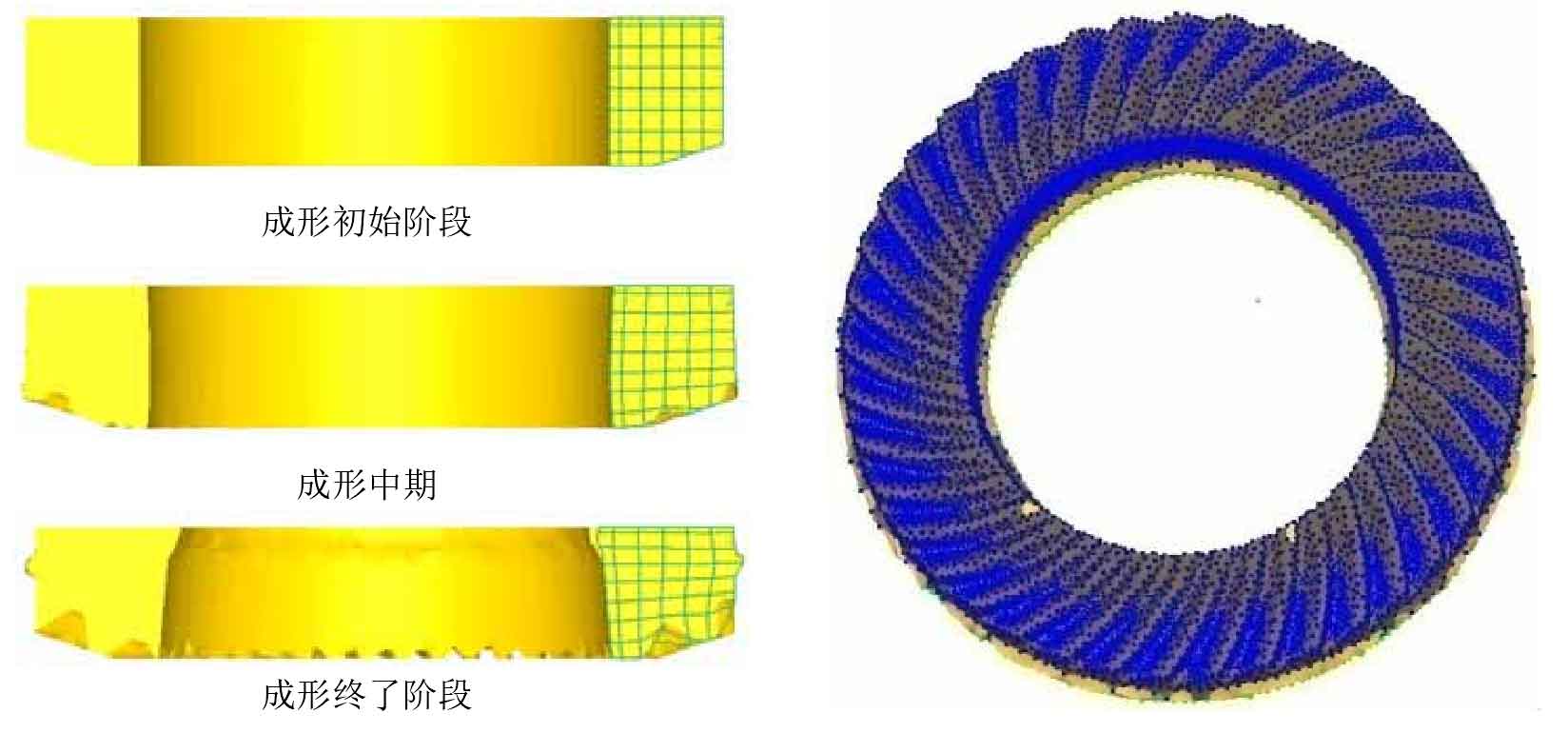

When the inner diameter D of the preform of spiral bevel gear is too large, the volume can be adjusted by changing the height h of the preform to ensure that it is equal to the volume of the formed part. Fig. 3 shows the change of finite element mesh of the blank at different stages in the process of forming spiral teeth when the inner diameter D of the preform is too large, which can reflect the change law of metal streamline. When the internal and external diameter of the preform is close to the formed part, the change of the blank finite element mesh in different stages is shown in Fig. 4.

Comparing Fig. 3 with Fig. 4, it can be seen that the internal diameter of the preform of spiral bevel gear is too large. At the end of forming, the deformation degree is large, the internal metal flow is violent, and the material filling the mold cavity is irregular, which is easy to cause the tooth shape filling to be not full. Therefore, the internal and external diameter of the preform should be close to the size of the formed part.