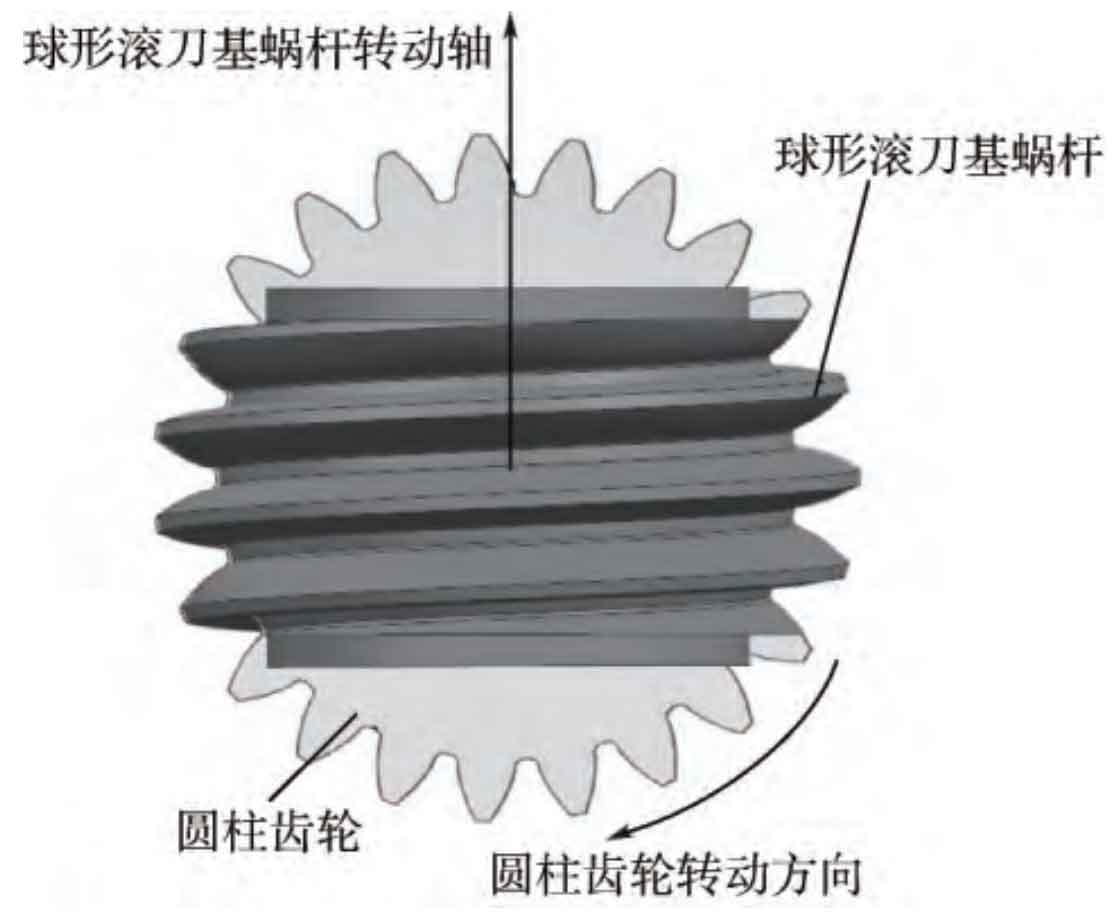

Similar to the evolution from rack to ordinary gear hob, the evolution process from cylindrical gear to spherical hob based worm can be obtained. As shown in Figure 1, it is assumed that the spherical hob base worm has the same section at each instantaneous section of the cylindrical gear rotation, so the rotation of the spherical hob base worm is equivalent to the rotation of the cylindrical gear in the section. The rotation ratio of cylindrical gear and spherical hob based worm is NW / N0, where: NW is the number of heads of spherical hob based worm, generally taken as 1; N0 is the number of teeth of the cylindrical gear. The spherical hob base worm rotates once, and the cylindrical gear just rotates one tooth.

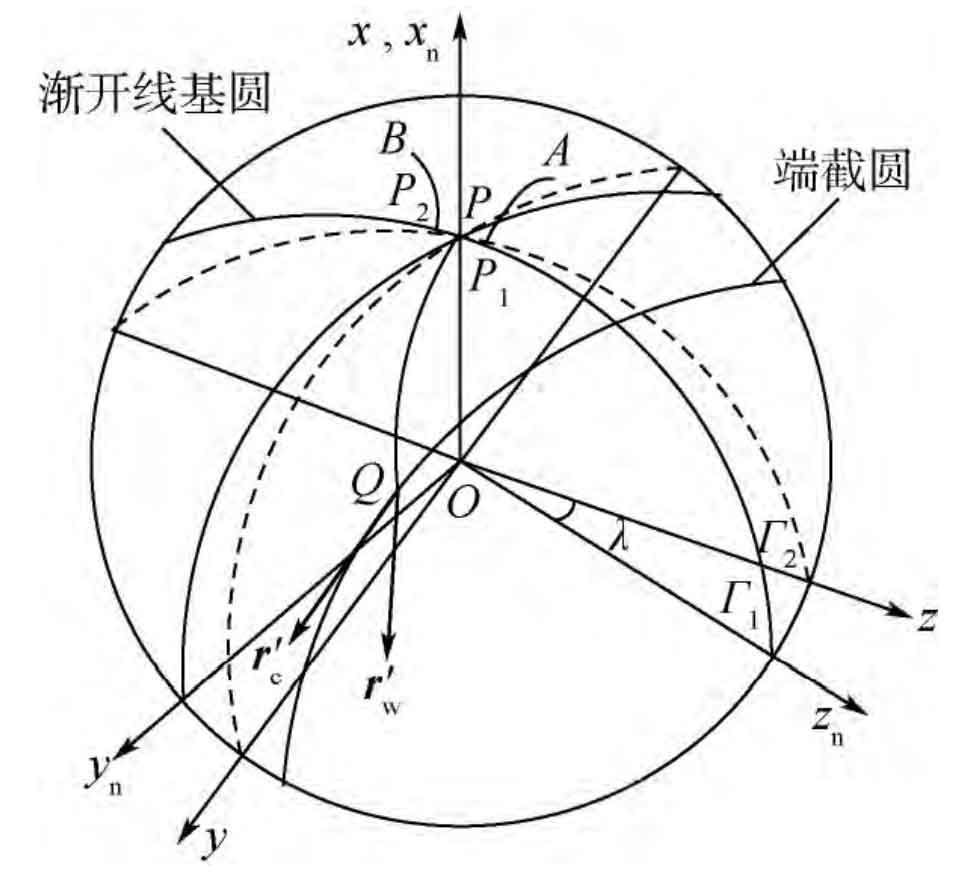

The base ball of the spherical hob base worm is shown in Figure 2, xnozn plane (i.e Γ 1 plane, i.e. normal section, is xoz plane (i.e Γ 2) plane rotation angle about X axis λ Get, λ It is the spiral rising angle of spherical grinding wheel worm. Γ 1 plane intersects with the base circle to generate a base circle from which involutes P1A and P2b are obtained, and the two involutes are symmetrical about xn axis. Point P is the intersection of the x-axis and the base sphere, and point q is a point on the spherical helix. Through point Q, it can be used as an end truncated circle plane perpendicular to the Zn axis. P1A and P2b rotate along the spherical helix PQ around the Z axis to obtain the base worm of the spherical hob.

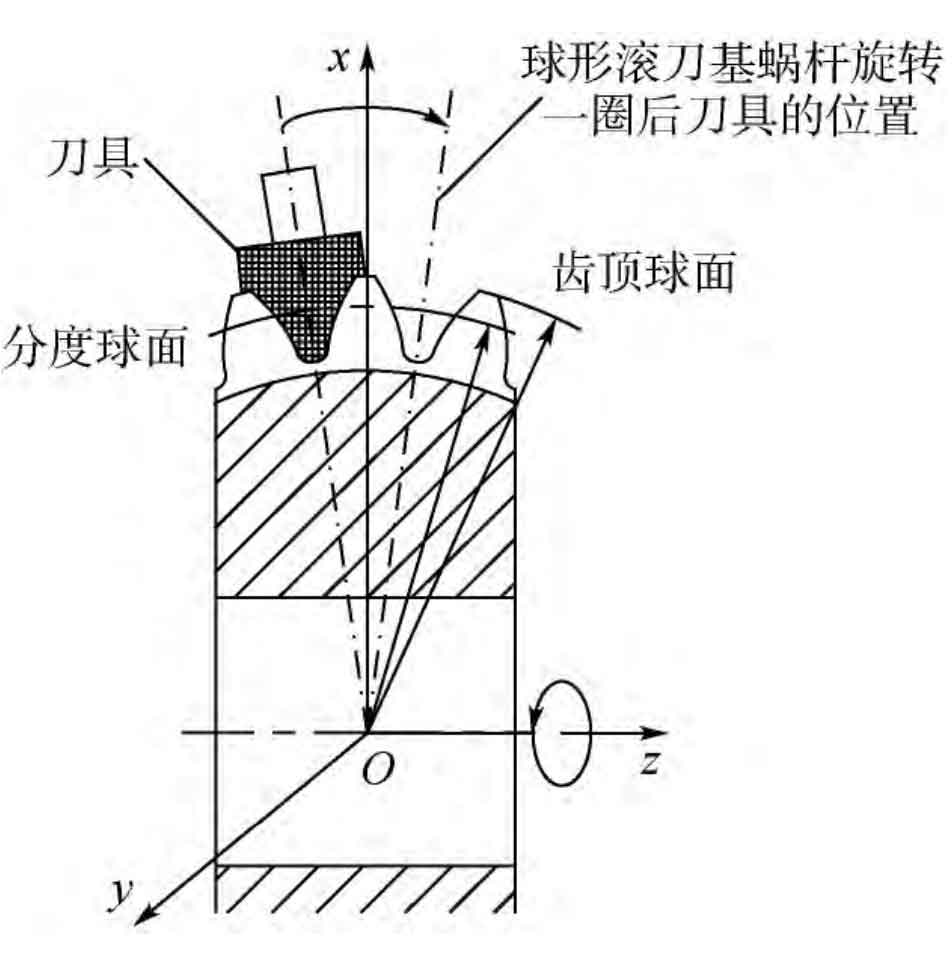

The manufacturing process of the traditional spherical hob based worm is shown in Fig. 3. During the rotation of the hob blank around its axis Z, the cutting tool with a specific tooth profile (the tooth profile is located at Γ 2) rotate around the y-axis in the xoz plane with a certain rotation ratio for cutting. Spherical helix obtained by this manufacturing method

The axial pitch is equal, and the tooth profile pitch on the shaft section is the same, but the normal pitch decreases gradually, and there is a certain error in the tooth profile pitch on the normal section. In addition, the tool profile used in this manufacturing method is complex and needs to be specially customized.

In fact, the cutting tool should rotate around the yn axis in the xnozn plane for cutting (the correct tooth profile of the tool is located at Γ 1) at the same time, the hob blank still rotates around the z-axis, that is, the tool cuts in the normal section, so that the normal pitch of the spherical helix is equal, so as to obtain the spherical hob base worm with correct involute tooth profile and pitch in the normal section. This manufacturing method can be realized theoretically on the multi axis linkage machine tool, Moreover, the cutting tool profile used is a standard involute shape.