Gears are critical components for motion and power transmission, characterized by constant-power transmission. Their performance largely determines equipment functionality, granting them strategic importance in national economy and defense. Geometric elements constructed tooth gears represent a novel gear type featuring convex-concave meshing point contacts, exhibiting superior load capacity and lubrication performance. These gears have been applied in aerospace, marine, mining, metallurgy, and small-module transmissions. After extensive research, machining methods including CNC profile machining, hobbing, worm wheel grinding, and form grinding have been established. However, gear shaving—an efficient and economical finishing process—remains unexplored for these gears. This study establishes fundamental design theories for cylindrical geometric elements constructed tooth gear shaving cutters and validates them experimentally.

1. Basic Meshing Principle of Cylindrical Geometric Elements Constructed Tooth Gear

Cylindrical geometric elements constructed tooth gears operate on conjugate curve meshing principles. Conjugate curves are defined as two smooth curves maintaining continuous tangential contact under specified motion laws. For parallel-axis cylindrical gear pairs, the relative velocity \( \mathbf{v}^{(12)} \) and normal vector \( \mathbf{n} \) satisfy:

$$ \mathbf{n} \cdot \mathbf{v}^{(12)} = 0 $$

The meshing equation in coordinate system \( S_1 \) is expressed as:

$$ \Phi(t, \phi_1) = \mathbf{n}_1 \cdot \mathbf{v}_1^{(12)} = 0 $$

Using the rack-generation method, the tooth surface equation for convex gears is derived as:

$$ \mathbf{r}_{2t} = \begin{bmatrix}

x_{2t} \\

y_{2t} \\

z_{2t}

\end{bmatrix} = \begin{bmatrix}

r_{2t} \cos \eta_{2t} \pm \rho_t \sin \alpha_t \\

r_{2t} \sin \eta_{2t} + \rho_t \cos \alpha_t \\

\frac{l_t}{\sin \beta_t} – \rho_t \cos \alpha_t \cot \beta_t + p_{2t} \eta_{2t}

\end{bmatrix} $$

For concave gears, the parabolic segment equation is:

$$ \mathbf{r}_{2a} = \begin{bmatrix}

x_{2a} \\

y_{2a} \\

z_{2a}

\end{bmatrix} = \begin{bmatrix}

\cos \eta_{2a} \left( \pm L \cos \alpha – t \sin \alpha \right) – \sin \eta_{2a} \left( \pm \frac{t^2}{2p} \cos \alpha + l_a \right) \\

\sin \eta_{2a} \left( \pm L \cos \alpha – t \sin \alpha \right) + \cos \eta_{2a} \left( \pm \frac{t^2}{2p} \cos \alpha + l_a \right) \\

p_{2a} \eta_{2a} \pm \cot \beta_a \left( L \sin \alpha + \frac{t^2}{2p} \sin \alpha \right)

\end{bmatrix} $$

2. Tooth Surface Equation of Cylindrical Geometric Elements Constructed Tooth Gear Shaving Cutter

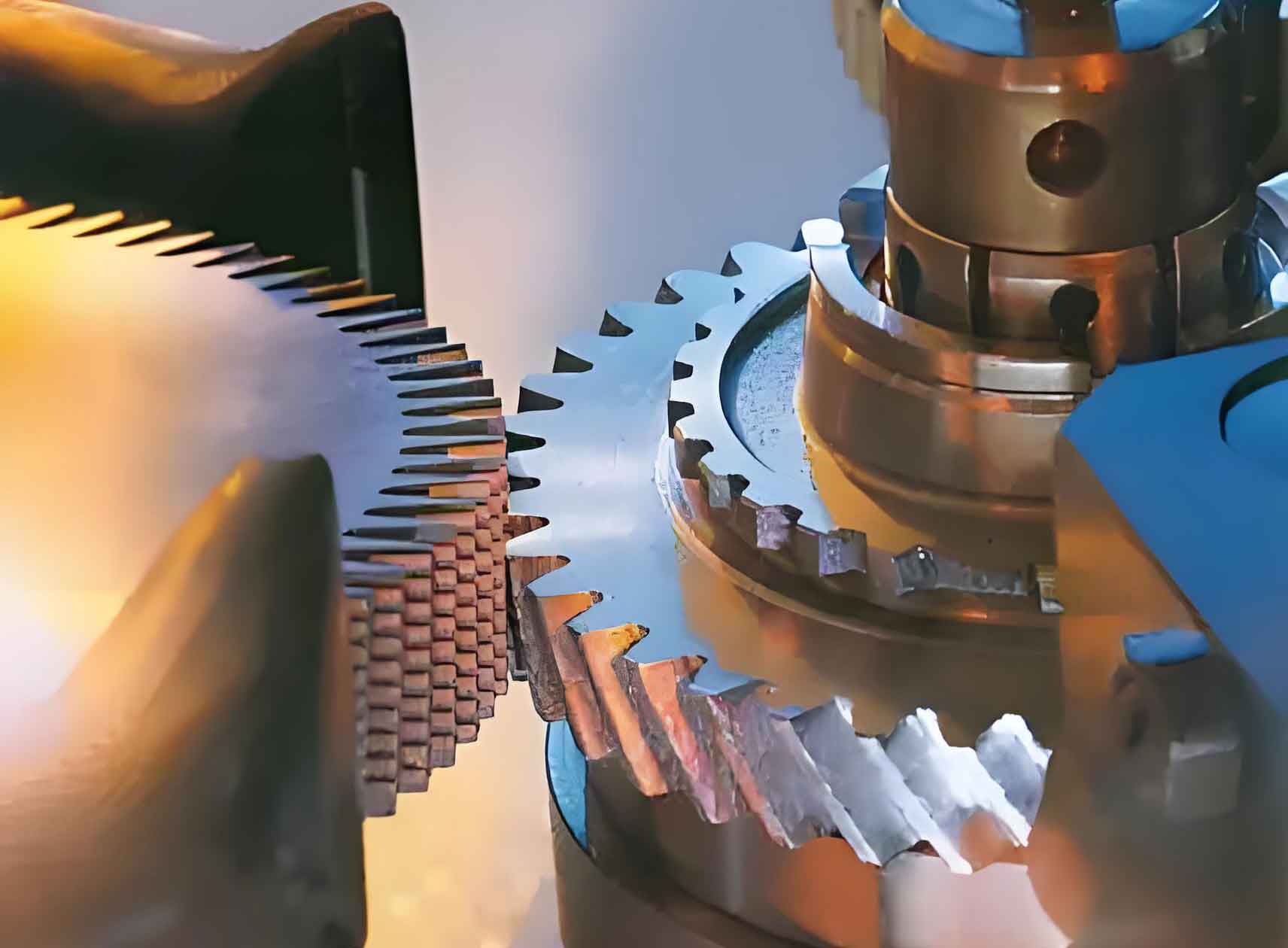

For two-point meshing convex-concave gear pairs, the shaving cutter tooth surface equations are derived based on spatial meshing theory. The coordinate system for gear shaving is established as shown:

The relative velocity vector during gear shaving is:

$$ \mathbf{v}^{(12)} = \begin{bmatrix}

\omega_2 (y_f \cos \Sigma – z_f \sin \Sigma) \\

\omega_1 (x_f – a) – \omega_2 x_f \cos \Sigma \\

\omega_2 y_f \sin \Sigma + v^{(1)}_0

\end{bmatrix} $$

The meshing equation for convex gears during gear shaving is:

$$ \rho_t \sin \alpha_t \left[ \beta_t \cos \beta_t + (\rho_t \sin \alpha_t – r_{2t}) \sin(\eta_{2t} – \phi_2) \right] – c_t n_{zt} = 0 $$

The shaving cutter tooth surface for convex gears is calculated as:

$$ \mathbf{r}_{qt} = \mathbf{M}_{10} \cdot \mathbf{M}_{02} \cdot \mathbf{r}_{2t} $$

Key design parameters for a 6-module gear pair are:

| Parameter | Symbol | Convex Gear | Concave Gear |

|---|---|---|---|

| Normal Module (mm) | \( m_n \) | 6 | 6 |

| Number of Teeth | \( Z_2 \) | 6 | 30 |

| Shaving Cutter Teeth | \( Z_1 \) | 41 | 30 |

| Shaft Angle (°) | \( \Sigma \) | 14 | |

3. Design Software Development for Cylindrical Geometric Elements Constructed Tooth Gear Shaving Cutter

A Python-based design software was developed using Eric7 IDE and PyQt6 framework. The algorithm design flow includes:

| Stage | Key Processes |

|---|---|

| Parameter Recommendation | Calculate contact trace start point and envelope radius |

| Tooth Profile Calculation | Solve gear tooth surface equations |

| Data Export | Generate UG-readable DAT files |

The modified involute tooth surface algorithm is implemented as:

def calc_inv_alpha(inv):

alpha_low, alpha_high = 0, 2

for _ in range(30):

alpha_mid = (alpha_low + alpha_high) / 2

if math.tan(alpha_mid) - alpha_mid > inv:

alpha_high = alpha_mid

else:

alpha_low = alpha_mid

return alpha_mid

Software interface modules include gear parameter design, strength verification, and shaving cutter data generation.

4. Experimental Study on Gear Shaving of Cylindrical Geometric Elements Constructed Tooth Gear

The gear shaving experiment was conducted on Y4232CNC2 machine with parameters:

| Parameter | Value |

|---|---|

| Spindle Speed (rpm) | 2000 |

| Feed Rate (mm/min) | 50 |

| Offset Distance (mm) | 9 |

Surface roughness measurements using Alicona InfiniteFocus G5 showed:

| Gear Type | Pre-Shaving Ra (μm) | Post-Shaving Ra (μm) |

|---|---|---|

| Convex Gear | 1.5362 | 0.6276 |

| Concave Gear | 1.5127 | 0.6563 |

The 60-84% reduction in surface roughness validates the gear shaving theory and cutter design methodology.

5. Conclusions and Prospects

1. Mathematical models for cylindrical geometric elements constructed tooth gear shaving cutters were established, with tooth surface equations derived using spatial meshing theory.

2. Design software incorporating parameter optimization, strength verification, and data export functionalities was developed.

3. Experimental results confirmed a 60-84% reduction in surface roughness after gear shaving.

Future work will integrate Tooth Contact Analysis (TCA) into the software and conduct transmission performance comparisons.