According to the interference diagram of hobbing helical gear and the change of width parameters of helical gear and length parameters of hob, the relationship between the size of large and small end of helical gear and the length of hob is analyzed. (the tooth top widths of the original gear at the radius of 105mm, 110mm and 115mm are 2.0045mm, 1.3574mm and 0.9172mm respectively). Select different lengths of hobs and find the minimum interference position between hobs and helical gears according to different feed positions of hobs, so as to determine the effective length of hobs. According to the interference analysis, when the hob length is too long, the relative motion of the hob and the helical gear interferes, resulting in the partial removal of the teeth of the helical gear in the machining process. By changing the length parameters of helical gear hob, the length of hob is shortened to meet the needs of machining, and then the hobbing of helical gear is realized.

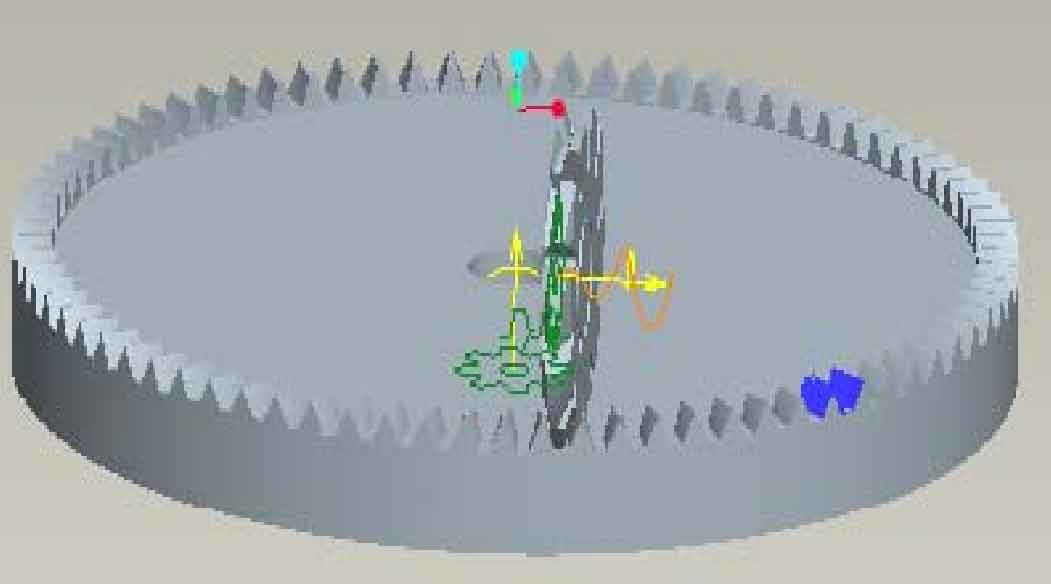

The longer the hob length, the greater the interference, the more tooth surfaces are cut off. If the hob is too long, all the teeth of the helical gear will be cut off. When the hob length is 10mm, most of the large end teeth of helical gear are cut off, while the small end teeth of helical gear are cut off. The shorter the effective length of the hob, the more complete the teeth of the helical gear are retained, but at the same time, ensure that the helical gear hob envelops the complete tooth profile of the helical gear (the minimum length of the hob is 6.2mm), so that the edge blade load of the hob participating in the processing should not be too heavy. When the effective length of the hob is ≤ 8mm, the hobbing simulation is almost consistent with the tooth profile of the helical gear theoretically, so it is determined that the effective length of the hob is 7mm, as shown in the figure.

According to the hobbing motion simulation and meshing interference principle of helical gear, the following points are obtained:

(1) In the feed movement, the hob feeds from the small end to the large end, and cuts off the four angular positions of the helical gear respectively, so that the small section tooth surface of the original model becomes narrower, and the tooth width of the large section becomes thicker or changes very little.

(2) The longer the hob length, the more serious the interference between the two in the movement process, so the larger the tooth area of the helical gear is cut off. If the hob is too long, all the teeth of the helical gear will be cut off. If the effective length of the hob is shorter, the teeth of the helical gear will remain more complete, but if the hob is too short, the tooth profile of the processed helical gear will not be a complete involute. Considering the mutual restriction conditions between the two and preventing the error caused by inaccurate tool setting, the hob with a length of 7mm shall be selected in the actual gear hobbing.