The demand for compact, high-performance power transmission systems has grown significantly in fields such as medical robotics, aerospace mechanisms, and portable industrial equipment. While the rotary vector reducer, commonly known as the RV reducer, is renowned for its high precision, substantial load capacity, and excellent stiffness, its conventional form factor is often too large for applications with stringent space constraints. This work presents the design, theoretical analysis, and verification of a novel, small-sized rotary vector reducer. The objective is to achieve a significant reduction ratio within a drastically minimized radial footprint, maintaining the core advantages of the RV transmission principle.

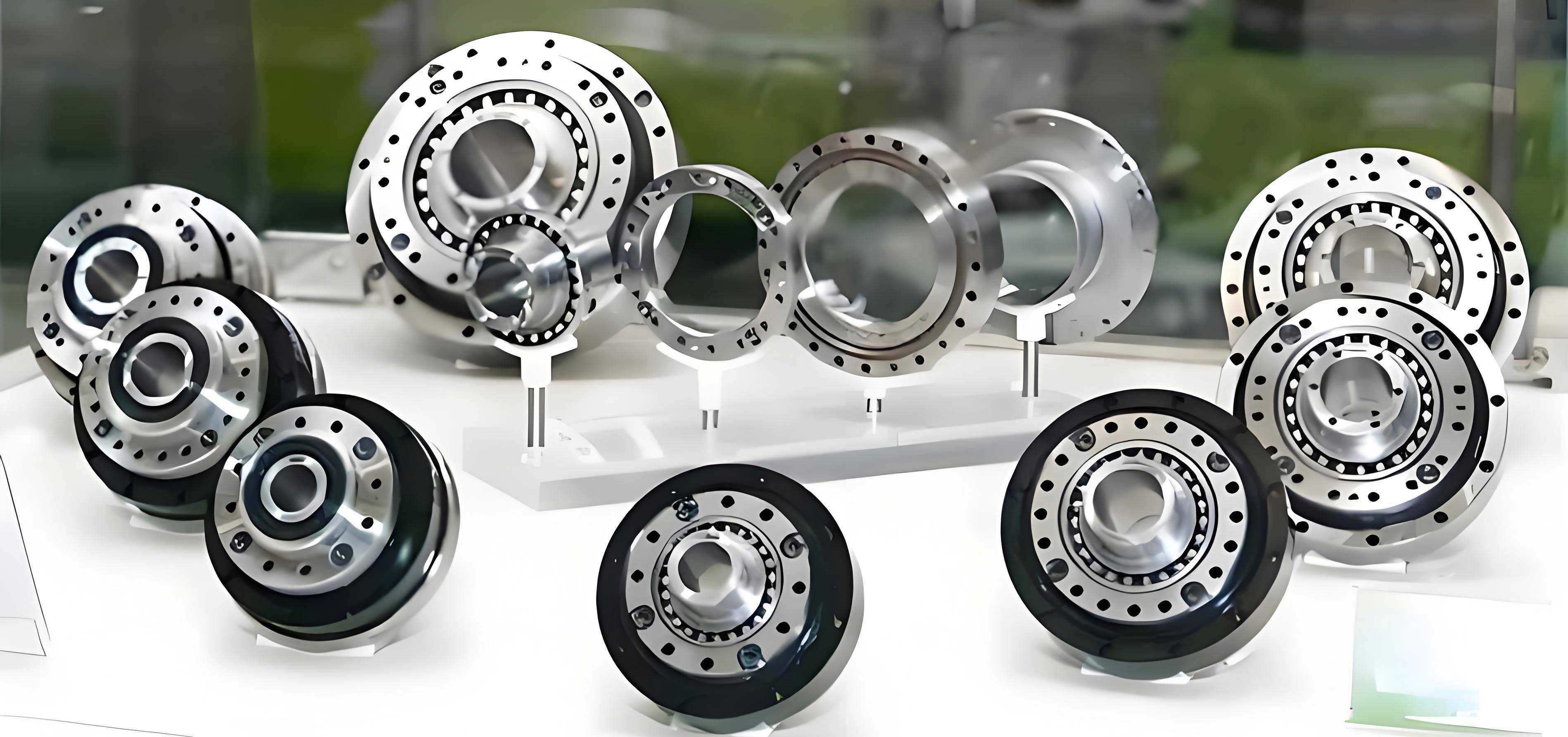

The compact rotary vector reducer retains the fundamental two-stage architecture of its larger counterparts. The primary stage consists of an involute planetary gear train, providing the first level of speed reduction and torque amplification. The secondary stage employs a cycloid-pin gear mechanism, which offers high reduction ratios in a compact space and is central to the high torque density of the rotary vector reducer. The integration of these stages within a minimal volume presents unique challenges in parameter selection, component sizing, and strength validation.

Structural Composition and Operational Principle

The proposed compact rotary vector reducer is mechanically composed of several key sub-assemblies. The first-stage involute transmission includes a central sun gear and multiple planetary gears. These planetary gears are mounted on eccentric shafts, which serve as the input cranks to the second stage. The second stage comprises cycloid disks that mesh with a ring of stationary pin gears housed in the pin housing. The output is facilitated through a set of pins on the output plate that engage with corresponding holes in the cycloid disks. A critical design adaptation for miniaturization is the use of standardized micro-ball bearings (e.g., MR95zz, MR104zz) as the crank bearings and support bearings, replacing the customary needle roller assemblies to accommodate smaller shaft and bore diameters.

The kinematic principle follows the standard rotary vector reducer logic but within a constrained space. The input motor drives the sun gear. This rotation is transmitted to the planetary gears, achieving the first speed reduction. Since the planetary gears are connected to the eccentric shafts, they cause the cycloid disks to undergo an eccentric orbiting motion (revolution) relative to the fixed pin gear ring. This engagement forces the cycloid disks to rotate (spin) on their own axes. This spin component is transferred directly, via the eccentric shafts, to the output plate at a 1:1 ratio. The output rotation is fed back into the planetary stage, creating a differential or closed-loop system that results in the final, greatly reduced output speed at the output plate. The total reduction ratio, \(i_{RV}\), of the rotary vector reducer is given by:

$$ i_{RV} = 1 + \frac{z_b}{z_g} \times \frac{z_2}{z_1} $$

where \(z_1\) and \(z_2\) are the tooth numbers of the sun and planetary gears, and \(z_g\) and \(z_b\) are the tooth numbers of the cycloid disk and the stationary pin gear, respectively.

Geometric Parameter Design for Miniaturization

The design of a compact rotary vector reducer requires a meticulous and interdependent selection of geometric parameters to satisfy conflicting demands of high reduction ratio, structural integrity, and minimal size.

First-Stage Involute Planetary Gear Design

For the involute stage, the primary constraints are achieving the necessary speed reduction while ensuring the overall diameter fits within the target envelope. A critical relationship links the center distance of the planetary stage, \(a\), to the pin gear distribution circle radius, \(r_p\), of the second stage: \(a = (0.5 \text{ to } 0.6) r_p\). This ensures balanced load distribution and structural harmony between stages. To keep the transmitted torque in the first stage manageable, the planetary gear ratio should satisfy \(z_2 / z_1 \geq 1.5\). Given the extreme miniaturization, a fine-pitch gear module must be selected. To avoid undercut on the small sun gear and to balance specific sliding and bending stresses for similar lifespan, profile shift is essential. The shift coefficients \(x_1\) (sun) and \(x_2\) (planetary) are determined based on the condition of equal maximum sliding coefficients \(\eta_{1max}\) and \(\eta_{2max}\) for the mating pair:

$$ \eta_{1max} = \frac{(\tan\alpha_{a2} – \tan\alpha’)}{(1 + z_1/z_2)\tan\alpha’ – \tan\alpha_{a2}} \cdot \frac{u+1}{u} $$

$$ \eta_{2max} = \frac{(\tan\alpha_{a1} – \tan\alpha’)}{(1 + z_2/z_1)\tan\alpha’ – \tan\alpha_{a1}} \cdot \frac{u+1}{u} $$

where \(u = z_2/z_1\), \(\alpha’\) is the operating pressure angle, and \(\alpha_{a1}, \alpha_{a2}\) are the pressure angles at the gear tooth tips. For this design, a module of \(m = 0.5\) mm was chosen. The final selected parameters for the compact rotary vector reducer’s first stage are summarized below.

| Parameter | Symbol | Value |

|---|---|---|

| Module | \(m\) | 0.5 mm |

| Sun Gear Teeth | \(z_1\) | 15 |

| Planetary Gear Teeth | \(z_2\) | 30 |

| Number of Planets | \(n_w\) | 3 |

| Operating Pressure Angle | \(\alpha’\) | 20° |

| Sun Gear Profile Shift Coefficient | \(x_1\) | +0.34 |

| Planetary Gear Profile Shift Coefficient | \(x_2\) | -0.34 |

| Center Distance | \(a\) | 11.25 mm |

| Contact Ratio | \(\epsilon_{\alpha}\) | 1.512 |

Second-Stage Cycloid-Pin Gear Design

The cycloid stage is the heart of the torque amplification in a rotary vector reducer. The design revolves around the pin gear distribution circle radius \(r_p\), which is the primary size driver. For a compact design targeting an output torque \(T_v\) of approximately 88.75 N·m, \(r_p\) was set to 20 mm. The tooth difference is typically one (\(z_b – z_g = 1\)). The eccentricity \(e\) is a crucial parameter derived from the shortening coefficient \(K_1\): \(e = K_1 r_p / z_b\). \(K_1\) influences the contact stress and cycloid disk tooth profile. A common range is \(0.5 < K_1 < 1\). For this compact rotary vector reducer, \(K_1 = 0.675\) was selected to optimize performance within the size limit. To prevent undercutting or pointed teeth on the cycloid disk, the minimum radius of curvature of the theoretical cycloid profile, \(\rho_{0min}\), must be greater than the pin radius \(r_{rp}\):

$$ \rho_{0min} > r_{rp} $$

where \(\rho_{0min} = -r_p \cdot a_{min}\) and \(a_{min} = \frac{27 z_g^3 (1-K_1^2)}{(z_g+2)^3}\). Furthermore, the pin diameter coefficient \(K_2 = \frac{r_p \sin(\pi / z_b)}{r_{rp}}\) should be between 1.5 and 2.0 to ensure adequate pin housing strength. The final geometric parameters for this stage are as follows.

| Parameter | Symbol | Value |

|---|---|---|

| Pin Distribution Circle Radius | \(r_p\) | 20.0 mm |

| Pin Radius | \(r_{rp}\) | 1.3 mm |

| Number of Pin Teeth | \(z_b\) | 30 |

| Number of Cycloid Disk Teeth | \(z_g\) | 29 |

| Eccentricity | \(e\) | 0.45 mm |

| Shortening Coefficient | \(K_1\) | 0.675 |

| Pin Diameter Coefficient | \(K_2\) | 1.608 |

Output Mechanism Sizing

The output mechanism uses pins on the output plate engaging with holes in the cycloid disks. The diameter of the output pins \(d_w\) and the diameter of the holes in the cycloid disks \(d_{gw}\) are related by the eccentricity: \(d_w = d_{gw} – 2e\). The distribution of these holes must ensure sufficient material strength in the cycloid disk. The minimum wall thickness \(\delta\) between adjacent holes and between the holes and the central bore should satisfy \(\delta \geq [\delta]\), where \([\delta]\) is typically taken as \(0.03r_p\).

Theoretical Force Analysis and Strength Assessment

Verifying the structural integrity of the compact rotary vector reducer under load is paramount. The analysis focuses on the most critically loaded components: the involute gears and the cycloid-pin mesh.

Load Distribution in the Involute Stage

The tangential force \(F_t\) on the sun gear from a single planetary gear is calculated from the input torque \(T_1\):

$$ F_{t21} = \frac{2 T_1}{n_w \cdot d_1} $$

where \(d_1\) is the pitch diameter of the sun gear. The radial force is \(F_{r21} = F_{t21} \cdot \tan\alpha’\). For an input power of \(P = 0.15\) kW and speed corresponding to the final output of 15 RPM and a total ratio of 61, the calculated forces are significant relative to the component size.

Load Distribution in the Cycloid Stage

The force analysis for the cycloid disk is more complex due to the multi-tooth contact. The resultant of all contact forces between the pins and the cycloid disk acts through the instantaneous center of rotation. The maximum force on a single cycloid tooth, \(F_{max}\), occurs when the contact normal is perpendicular to the direction of eccentricity. It is given by:

$$ F_{max} = \frac{2.2 T_v}{r_p K_1 z_g} $$

where \(T_v\) is the output torque. The factor 2.2 accounts for an assumed load imbalance factor of 1.1 and the fact that torque is shared between two cycloid disks (180° out of phase), so each disk transmits approximately \(0.55T_v\). Substituting the values for this compact rotary vector reducer yields \(F_{max} \approx 498.7 \text{ N}\).

Strength Verification Calculations

Material selection is key for a miniaturized, high-stress application. For the involute gears, a case-hardening steel like 20CrMnTi is chosen. For the cycloid disk and pins, bearing steel GCr15 is selected for its high contact fatigue strength.

Involute Gear Strength: Both bending stress \(\sigma_F\) and contact stress \(\sigma_H\) are checked using standard AGMA-inspired formulas. The contact stress formula is:

$$ \sigma_H = \sqrt{ \frac{2 K_H T_1}{b d_1^2} \cdot \frac{u+1}{u} } \cdot Z_H Z_E Z_{\epsilon} $$

where \(K_H\) is the load factor, \(b\) is the face width, \(Z_H\) is the zone factor, \(Z_E\) is the elasticity factor, and \(Z_{\epsilon}\) is the contact ratio factor. Calculations confirmed that both \(\sigma_F\) and \(\sigma_H\) were below the allowable limits for 20CrMnTi.

Cycloid-Pin Contact Strength: The contact between a pin and the cycloid disk is modeled as contact between two cylinders. The maximum contact stress \(\sigma_{H2}\) is computed using the Hertzian formula:

$$ \sigma_{H2} = 0.418 \sqrt{ \frac{F_i}{B \rho_d} \cdot \frac{2 E_1 E_2}{E_1 + E_2} } $$

Here, \(F_i\) is the contact force (using \(F_{max}\)), \(B\) is the cycloid disk width, \(E_1\) and \(E_2\) are the elastic moduli, and \(\rho_d\) is the relative curvature. The curvature of the cycloid profile \(\rho_0\) varies with the rotation angle \(\varphi_i\):

$$ \rho_0 = \frac{r_p (1 + K_1^2 – 2K_1 \cos \varphi_i)^{3/2}}{K_1(1+z_b)\cos\varphi_i – (1+z_b K_1^2)} $$

The relative curvature is \(1/\rho_d = 1/r_{rp} – 1/\rho_0\). The calculation showed the maximum contact stress was well within the allowable limit for GCr15 material.

Finite Element Simulation and Validation

To validate the theoretical design and strength calculations for the compact rotary vector reducer, detailed static finite element analysis (FEA) was performed on both transmission stages.

Involute Gear Pair Simulation: A single sun-planet pair was modeled with appropriate boundary conditions. The sun gear was given a fixed rotational displacement corresponding to the input torque, while the planetary gear was constrained to rotate about its axis. Contact was defined with friction. The mesh was refined at the contact zones. The FEA results provided contour plots of deformation, von Mises stress, and, most importantly, contact stress on the tooth flanks.

Cycloid-Pin Mechanism Simulation: A full 360-degree model of one cycloid disk engaging with the fixed pin ring was constructed. The pins were modeled as part of a rigid pin housing. A fixed support was applied to the pin housing. A torque was applied to the cycloid disk’s inner surface, and displacement constraints allowed only rotation about its central axis. The contact between all pin and cycloid tooth pairs was defined as frictionless for the initial static analysis.

| Component | Theoretical Stress [MPa] | FEA Stress [MPa] | Allowable Stress [MPa] | Error |

|---|---|---|---|---|

| Involute Gear Pair | 664.94 | 703.3 | 1260 | 5.77% |

| Cycloid-Pin Mesh | 263.76 | 234.68 | 1300 | 11.03% |

The FEA results showed excellent correlation with the theoretical predictions. For the involute gears, the maximum contact stress error was approximately 5.8%. For the cycloid-pin contact, the error was slightly higher at about 11.0%, which is still within an acceptable range for complex mechanical systems involving multi-tooth contact and simplified theoretical models. The von Mises stress distributions from FEA also confirmed that stress concentrations were within safe limits and aligned with expectations from theoretical bending stress calculations. Crucially, all simulated stress values were significantly lower than the material yield and endurance limits, confirming the structural integrity of the proposed compact rotary vector reducer design.

Discussion and Concluding Remarks

The design and analysis process detailed herein demonstrates the feasibility of developing a highly compact rotary vector reducer. The core challenge lay in reconciling the conflicting requirements of extreme miniaturization with the need for high torque capacity and reliable operation. This was addressed through a systematic approach: interdependent parameter optimization across both transmission stages, careful material selection for high specific strength, and the strategic use of commercially available micro-bearings to enable smaller shaft diameters.

The theoretical force and stress analysis, based on established principles for rotary vector reducers, provided a solid foundation for the initial design. The subsequent finite element analysis served as a critical validation tool. The close agreement between the theoretical contact stresses and the FEA results—with errors of 5.77% for the involute stage and 11.03% for the cycloid stage—strongly supports the correctness of the analytical models and the rationality of the geometric parameter selection. The discrepancies are attributable to simplifications in the theoretical contact models, assumptions about load sharing, and the idealized boundary conditions in FEA.

This work successfully presents a viable design framework for a small-sized rotary vector reducer. The proposed geometry, with a pin gear circle radius of only 20 mm, represents a substantial reduction in size compared to standard industrial units. The integrated theoretical and computational verification confirms that the design can sustain the intended operational loads. Future work will focus on the detailed design of lubrication systems for micro-bearings, dynamic analysis to assess vibration and noise, tolerance analysis for manufacturability, and ultimately, the prototyping and experimental testing of the compact rotary vector reducer to validate its dynamic performance and durability in real-world applications.