At present, there is little research on die modeling and precision forging process of equal high tooth spiral bevel gear. Most researchers mainly study spur bevel gear and spiral bevel gear. Zhang Lin developed the precision forging process of spur bevel gear based on the central split flow method, developed two sets of precision forging dies for pre forging split flow area and split flow final forging, and briefly analyzed the key points of structural design of precision forging die. Based on the modeling process of hot precision forging die for spur bevel gear, Zhang Hongbin established the three-dimensional modeling system of precision forging die for spur bevel gear through UG secondary development language, focusing on four modules: modeling of tooth shape entity, modeling of gear matrix, modeling of precision forging die and assembly of precision forging die, Figure 1 shows the mold model under virtual assembly. He Wangzhi designed the bearing type spiral bevel gear precision forging die by studying the precision forging process of spiral bevel gears at home and abroad, further explored the strain field, velocity field and wear of the precision forging die, and studied the effects of different die structures and related parameters on the distribution of demoulding force and stress field, The forging simulation is carried out for many times to explore the influence of process parameters in the forging process on the temperature field and stress field of the forging die.

In the modeling of precision forging die, many researchers use secondary development tools for 3D modeling of precision forging die. Qimuge and others conduct automatic modeling research on the mold through UG secondary development tools, so as to improve the modeling efficiency of the mold and reduce the processing time. Wang et al. Established the three-dimensional automatic modeling system of gear precision forging die by using VB program language in SolidWorks software, and analyzed in detail the modeling process of three-dimensional solid model of precision forging die, the relationship between interface and model parameters. By inputting the modeling parameters in the interactive interface of VB language, the three-dimensional solid model of gear and precision forging die can be obtained. The three-dimensional automatic modeling system not only improves the modeling efficiency of gear precision forging die, but also improves the design quality of precision forging die.

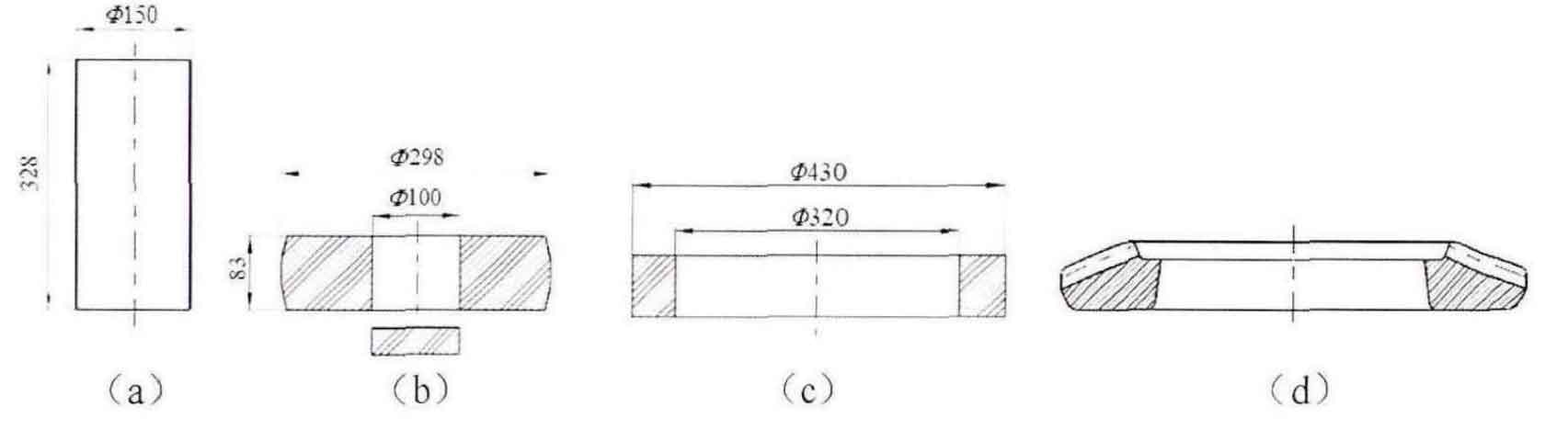

In terms of precision forging, skrockim put forward a series of relevant studies on gear precision forging and forming, and learned through relevant reports: compared with mechanical cutting methods, gear precision forging and forming can increase the bending strength and contact fatigue life of gears by 20%, and reduce the cost. Zhao Jun and others pointed out the complexity of gear forgings and excessive helix angle in view of the movement between forgings and dies in the demoulding process of spiral bevel gears. Gao et al. Developed a new forging technology method of gear, and analyzed its forging process with the help of deform simulation software. The results show that this method can improve the forging process quality of spiral bevel gear and reduce the scrap rate. Ding Ruiliang asked to determine the forging process by analyzing the forging process of spiral bevel gear, establish the three-dimensional solid model of gear forging and precision forging die, and finally optimize the forging process and analyze the grid, load and other related contents through deform simulation software. Li Xinrui et al. Developed a new forging process method of spiral bevel gear, and conducted forging simulation to study its forging process. At the same time, by extracting the data of die tooth shape, analyzing its displacement change and discussing its deformation law, figure 2 shows the forging process method of spiral bevel gear. Kanani et al. Studied the near net shape forming process of spur gear at room temperature through deform simulation software, analyzed the change of load and the distribution of streamline in the gear, and studied the blank flow state and velocity flow direction under different strokes.

Due to the complex tooth profile structure of equal height gear and less research on equal height gear, it is impossible to systematically understand the modeling process and forging technology of precision forging die of equal height spiral bevel gear. In addition, straight bevel gear and spiral bevel gear are in the same row and column as bevel gears with equal height teeth, which have certain commonalities in some aspects. Therefore, according to the structural characteristics of straight bevel gear and spiral bevel gear, through the study of the die modeling process and forging technology of the two gears, It provides an important basis for the research of precision forging die and forging process of equal height spiral bevel gear.