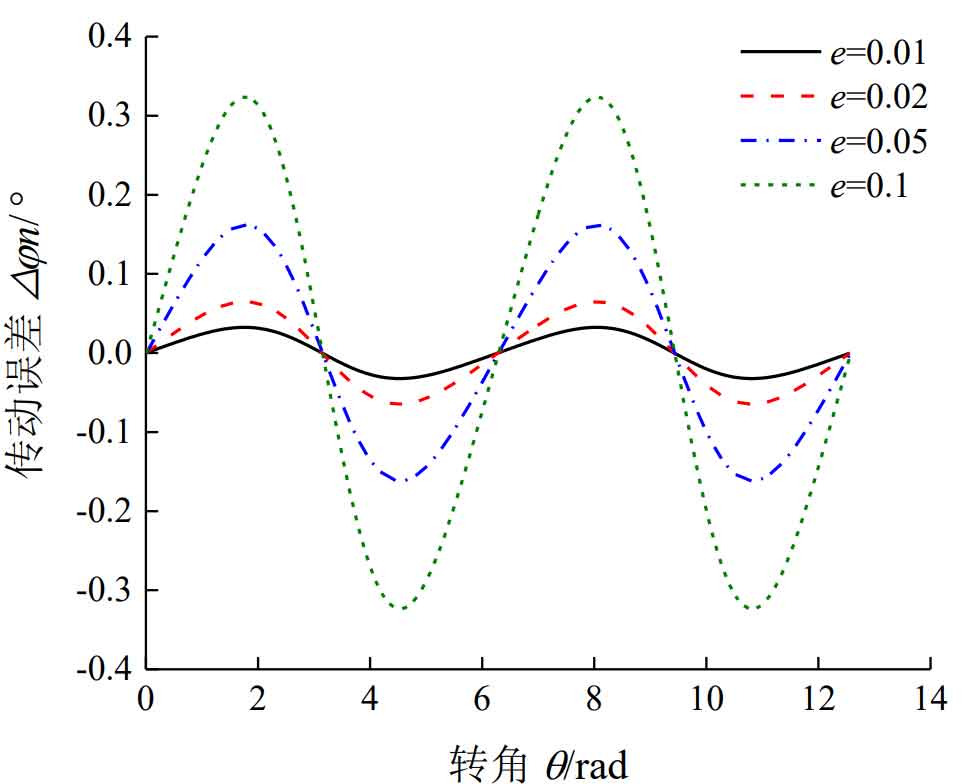

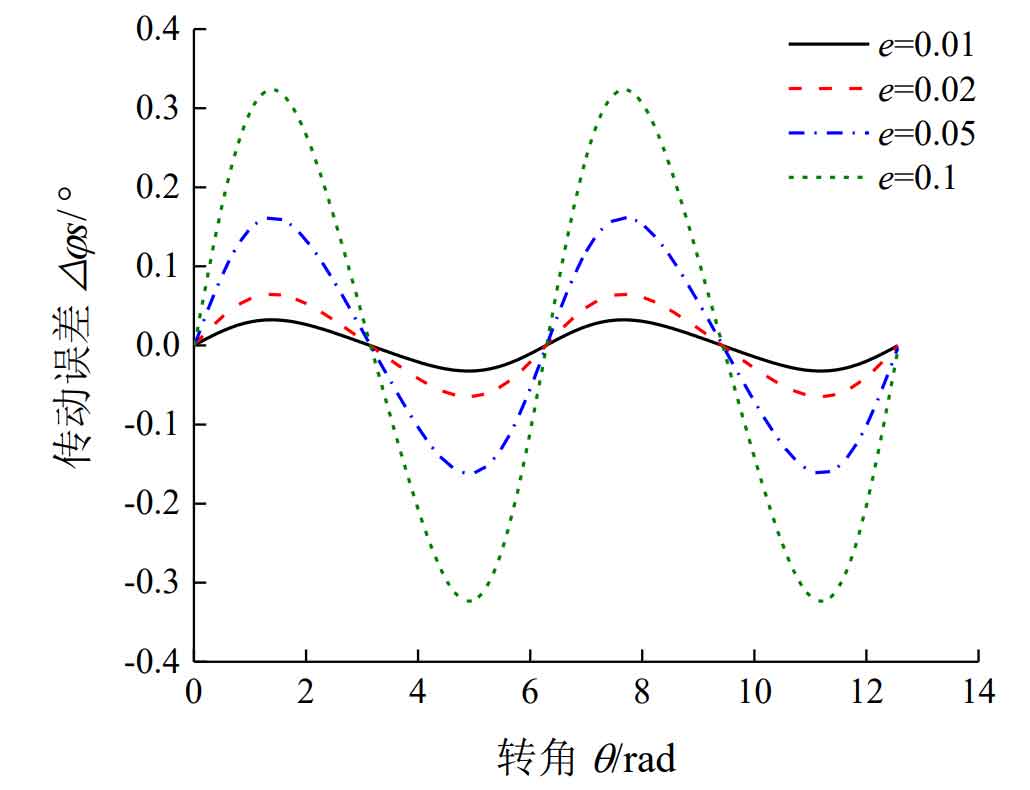

Figure 1 shows the relationship between transmission error of non-circular gear and eccentricity. With the increase of eccentricity, both clockwise transmission error and counterclockwise transmission error show an increasing trend. The greater the eccentricity, the greater the amplitude of transmission error. In contrast, the distribution law of non-circular gear transmission error under the two kinds of steering has a certain relationship with the rotation angle of the gear. Under the same eccentricity, the distribution law of the clockwise transmission error curve and the counterclockwise transmission error curve are basically the same, only the rotation angle corresponding to the numerical value and the extreme value has a certain difference.

In the installation process of gears and bearings, there will be a small amount of misalignment error and deformation error, resulting in the center distance error between gear pairs. To a certain extent, the center distance error can be equivalent to the eccentric error of the gear pair, and the eccentric error of the gear is an important factor that causes the gear transmission error. Generally, the cause of gear eccentricity error is the eccentricity and skew of the gear base circle axis relative to the rotation axis. The non-circular gear pair used in the analysis is a pair of gear pairs in the non-circular gear reversing device (Fig. 2). Its rotation center is not at the geometric center, so there is eccentricity. Therefore, it is of certain significance to analyze the influence of eccentricity error on the non-circular gear transmission error.

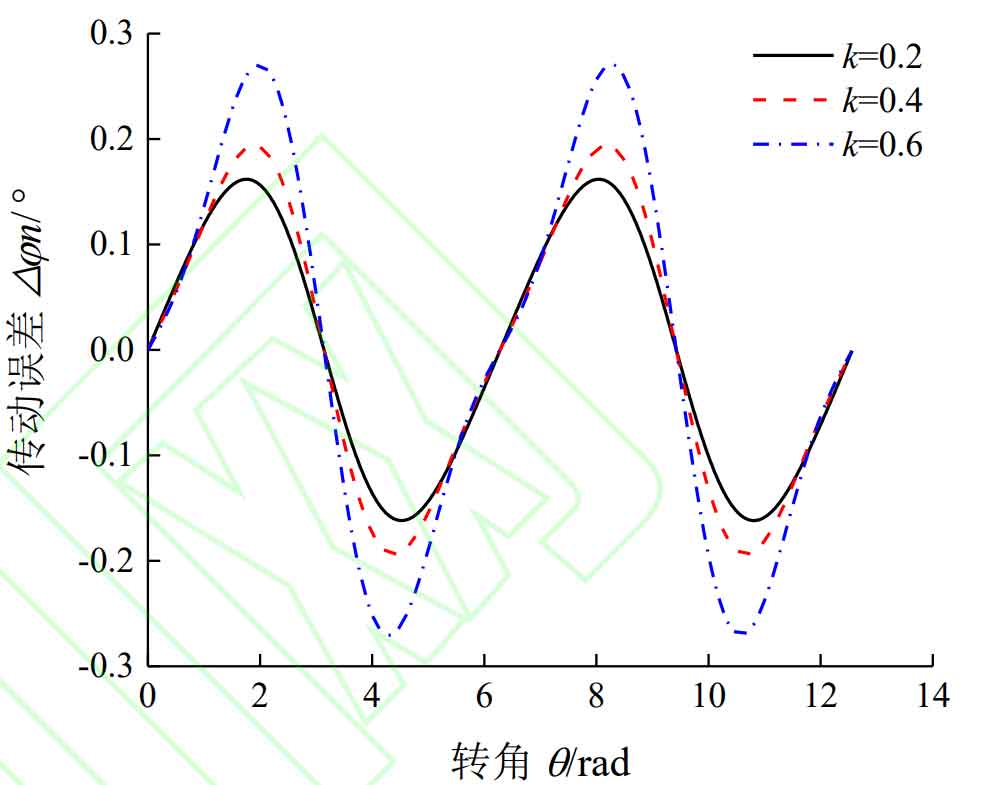

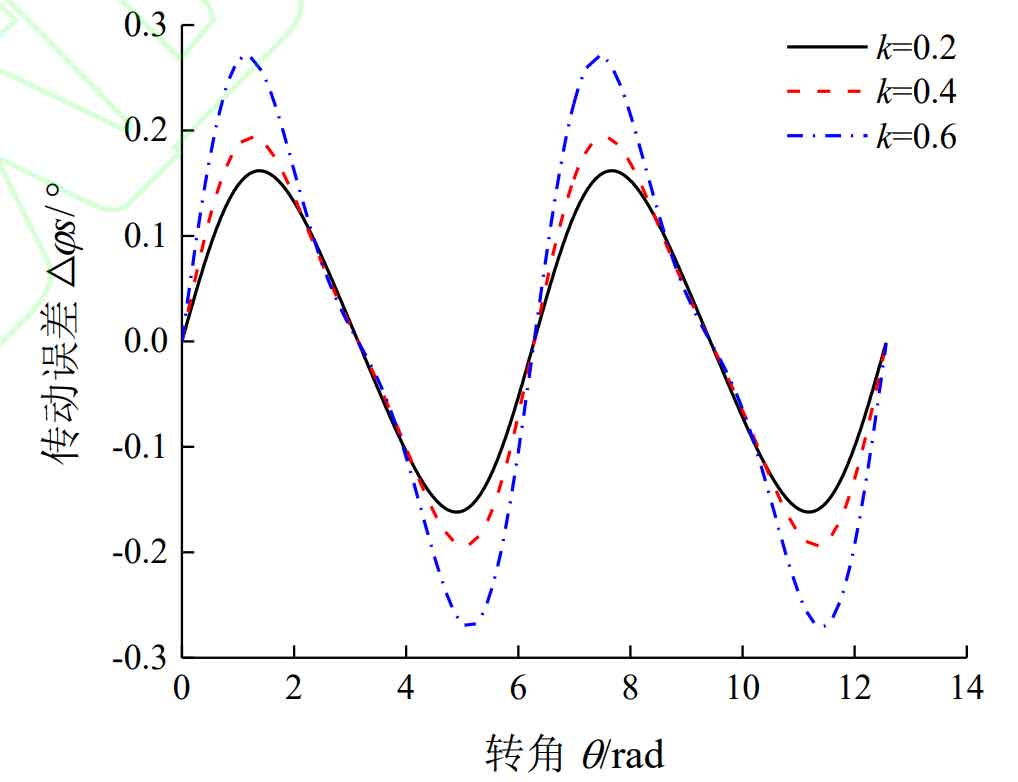

The variation trend of transmission error with eccentricity error of non-circular gear system with eccentricity of 0.3 is shown in Figure 3. With the increase of eccentricity error, the periodicity of non-circular gear transmission error under two kinds of steering is gradually obvious, and the amplitude of transmission error is also increasing. The distribution law of the counterclockwise transmission error curve and the clockwise transmission error curve under the same eccentric error condition is basically the same, but there is a certain difference in value. Therefore, the influence of transmission error caused by eccentricity can be reduced by improving the design accuracy, machining accuracy and installation accuracy of non-circular gears.