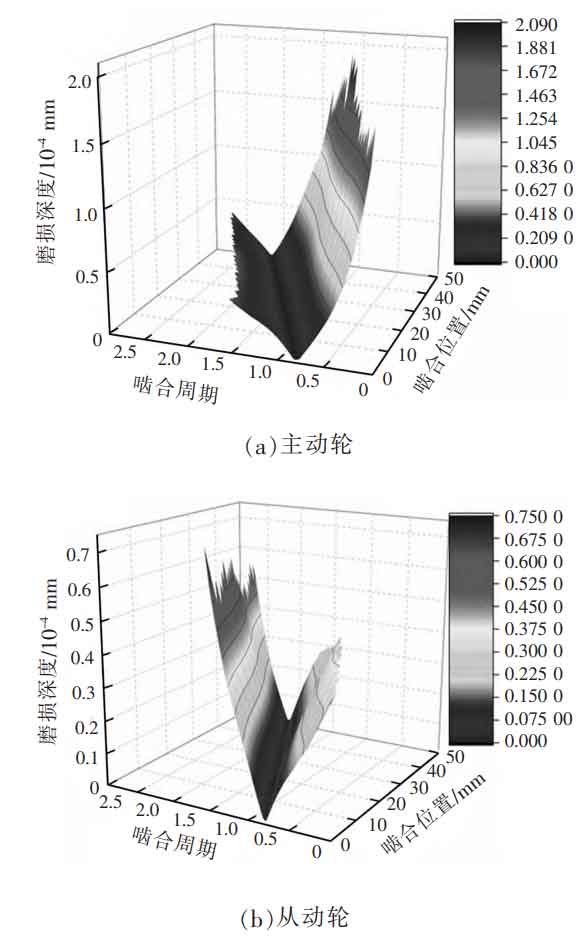

Helical gear transmission passes through 1 × The cumulative wear depth distribution of the driving and driven gear tooth surfaces after 104 load cycles is shown in the figure.

It can be seen from the figure that in the entire meshing area, the cumulative wear depth distribution rule of the tooth surfaces of the driving and driven gears is almost consistent, with only a certain difference in numerical value. The maximum wear depth of the two gears occurs at the root meshing position, and the wear depth of the tooth root and top meshing positions is greater than the wear depth near the node; In a helical gear transmission system, the cumulative wear depth of the driving gear tooth surface is significantly higher than that of the driven gear tooth surface. The maximum tooth surface depth occurs at the meshing position of the driving gear tooth root, and the cumulative wear depth near the node is almost zero. Compared to the driven gear, the driving gear participates in the meshing cycle more times, and the relative sliding distance generated by the meshing tooth surface is larger, resulting in a larger cumulative wear depth of its tooth surface; The relative sliding speed and sliding distance of the gear at the pitch circle position are 0. It is considered that the gear performs pure rolling at this position, and the tooth surface almost does not wear at this position.