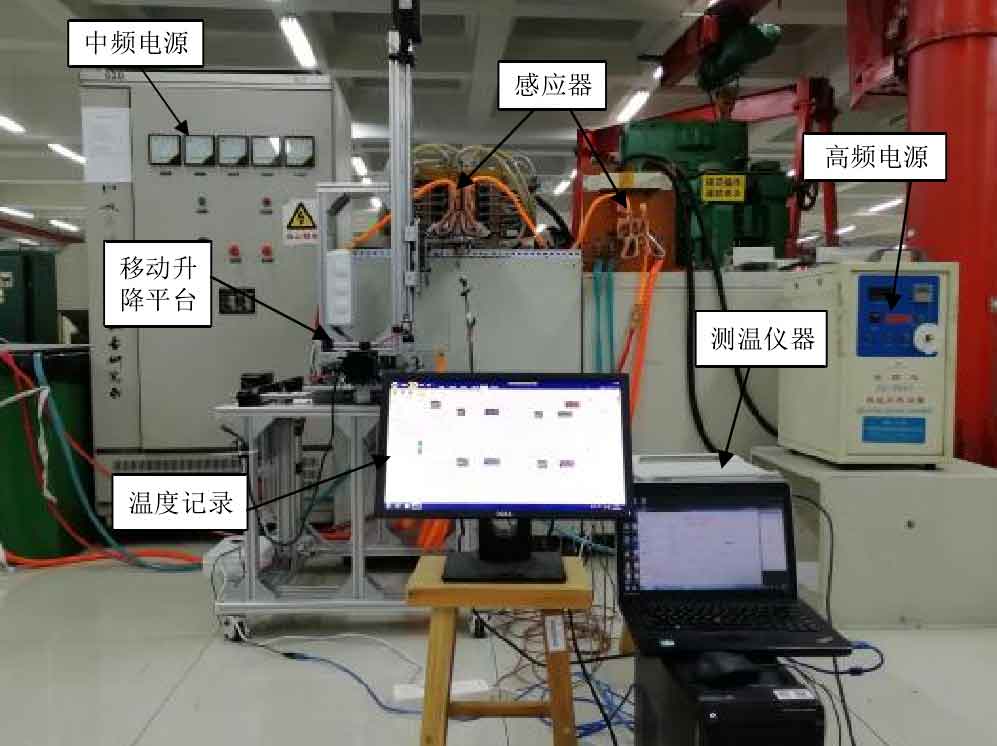

Before the double frequency induction heating experiment of bevel gear, it is necessary to build the experimental platform, process and install the induction coil, install the water cooling system, debug and install the temperature measuring equipment, etc.

(1) Temperature measuring instrument: the temperature measuring instrument used in the experiment is the general dynamic signal tester of Donghua company. The temperature measurement error of the recorder is – 0.5 ℃ ~ 1290.5 ℃. The recording instrument is a desktop computer, which is equipped with Donghua test dhdas dynamic signal acquisition and analysis system software. During the experiment, this software is used to collect and record the temperature value.

(2) Lifting platform: a platform that can be lifted and moved horizontally was built in the early stage. During the experiment, the platform was controlled by personal notebook. During the experiment, the position of bevel gear was adjusted to realize the switching of medium and high frequency current.

(3) Induction coil and water cooling system device: according to the coil structure parameters determined in Chapter 3, the induction coil is customized and processed in the factory. The structure of medium and high frequency induction coil is only different in installation size. The coil is installed on the power supply. During the experiment, the water pump is used to cool the induction coil independently.

(4) Bevel gear specimen: the parameters of the bevel gear specimen used in the experiment are the same as those of the numerical model used in the previous induction heating numerical simulation analysis, which are standard involute bevel gears with 15 teeth and 12 modulus.

(5) Dual frequency induction heating experimental platform: the dual frequency induction heating experimental platform of bevel gear is built by using the medium and high frequency power supply in the laboratory, as shown in the figure.