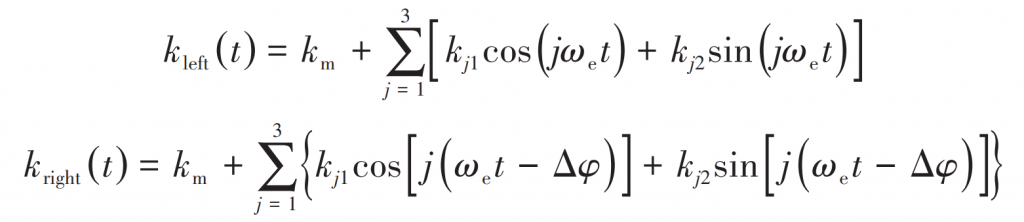

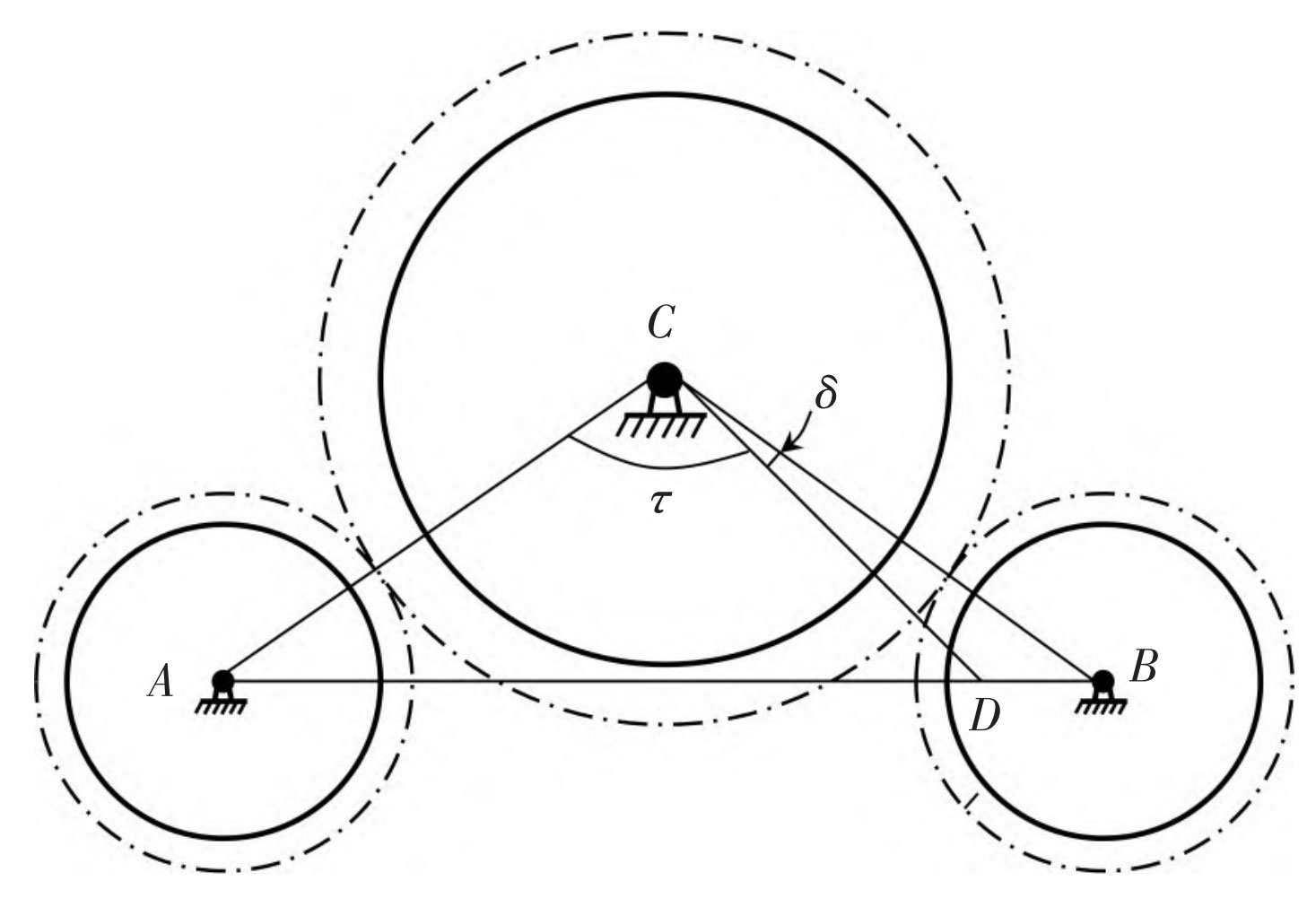

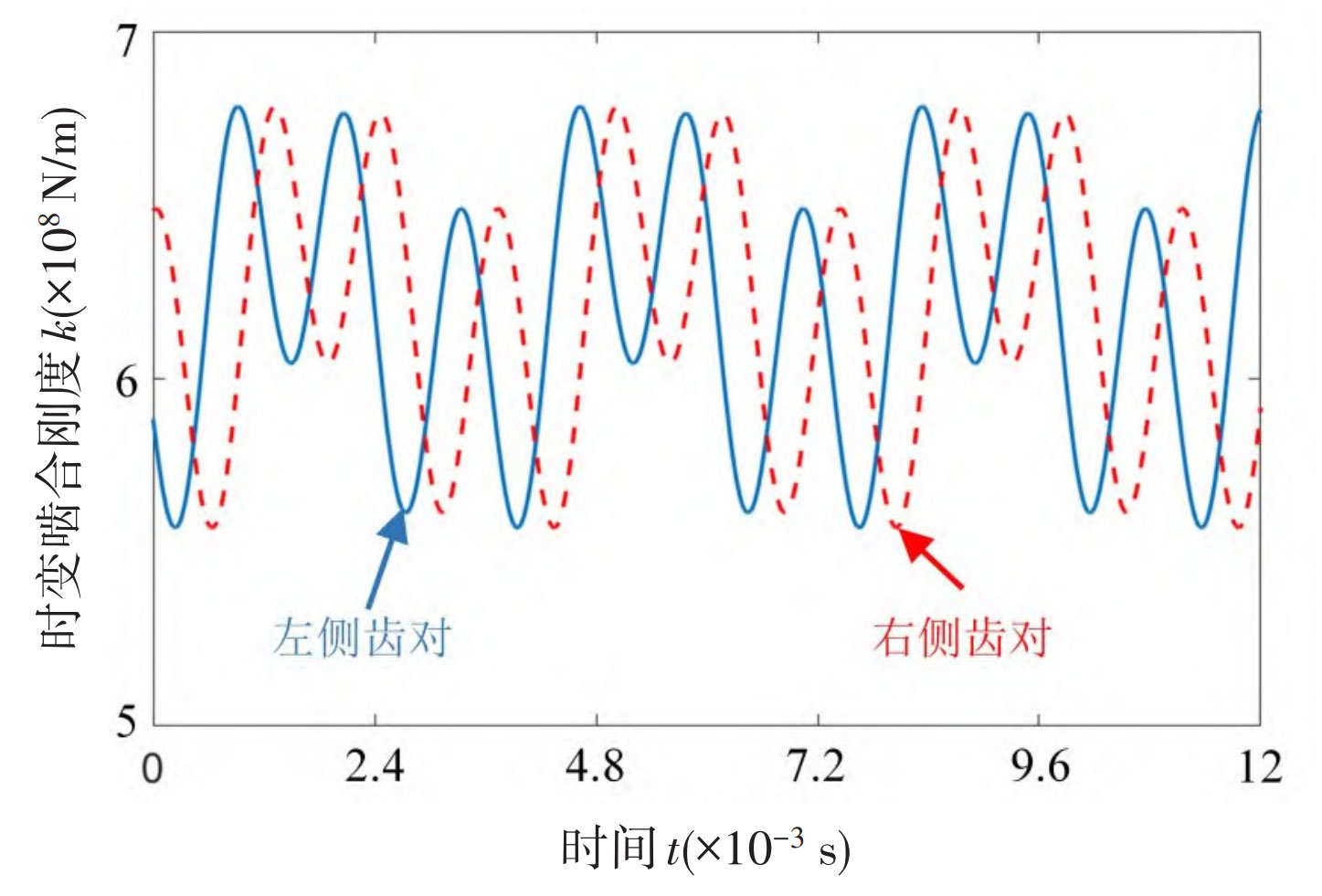

Due to the layout structure of dual input single output helical gears, as shown in Figure 1, the meshing process of the left and right helical gear pairs is difficult to fully synchronize, and there is a certain phase difference in the stiffness excitation on both sides. Points A, B, and C are fixed support points for the main and driven gears, and in most cases, the number of teeth between ∠ ACB( χ) Not an integer, will χ Divide into integer parts τ And decimal parts δ。 The difference in stiffness excitation time between the left and right drive gear pairs is Δ t = 2π δ/ z1 ω 1. The phase difference can be expressed as Δφ = ω e(2π δ/ z1 ω 1)。

| Structural parameters | Driving wheel/driven wheel |

| Number of teeth | 50/100 |

| Modulus/mm | 4 |

| Pressure angle/(°) | 20 |

| Helix angle/(°) | 10 |

| Tooth width/mm | 50 |

| Poisson’s ratio | 0.3 |

| Elastic modulus/Pa | 2.06×10^11 |

| Overlap ratio | 0.69 |

| Transverse contact ratio | 1.76 |

| Total overlap | 2.45 |

When ∠ ACB=120 ° and the parameters of the helical gear are shown in the table, the meshing stiffness of the left and right sides can be obtained through the formula, and the stiffness curve is shown in Figure 2.