Helical gears are widely used in high-speed and heavy-duty applications due to their advantages such as smooth transmission, large coincidence, and good meshing performance. This material has impact and wear resistance characteristics and is widely used in gear boxes for wind power generation, ships, and automotive rear axles. However, when the equipment is running at high speed, due to the large load on the helical gear, it is easy to generate gear tooth vibration noise, large meshing in and out impact, and other issues, which can lead to various failure modes of the helical gear, thereby reducing the transmission accuracy and service life of the helical gear pair. With the continuous development of high-precision equipment, various mechanical components have increasingly high requirements for the performance of helical gears.

In the actual transmission process of helical gears, due to the impact of installation and manufacturing errors, load deformation, there are often failure modes such as tooth surface deflection, gluing, and tooth root fracture. By slightly modifying the tooth surface, the contact area of the tooth surface can be optimized and the meshing performance of the helical gear can be improved. Fu Xuezhong proposed that the modified surface fitted by cubic B-splines and the theoretical tooth surface of the pinion be superposed to form an accurate topological modified tooth surface. The calculation models for TCA and LTCA of the pinion topological modified helical gear pair were established, and the correctness of the theoretical analysis was verified by experiments. Li Enshi et al. established a simplified finite element full tooth model, obtained the precise modification amount of the tooth profile through the secondary modification method, and compared the changes in the contact stress region of the tooth surface before and after the modification, indicating that the tooth profile modification can effectively improve the meshing performance of helical gears. Ren Xiaozhong conducted a three-dimensional topological modification of the internal helical gear, established a formula for analyzing the transmission error of the helical gear pair, and conducted an example analysis using finite element method to verify the trend of transmission error amplitude changes under different conditions with different modification coefficients.

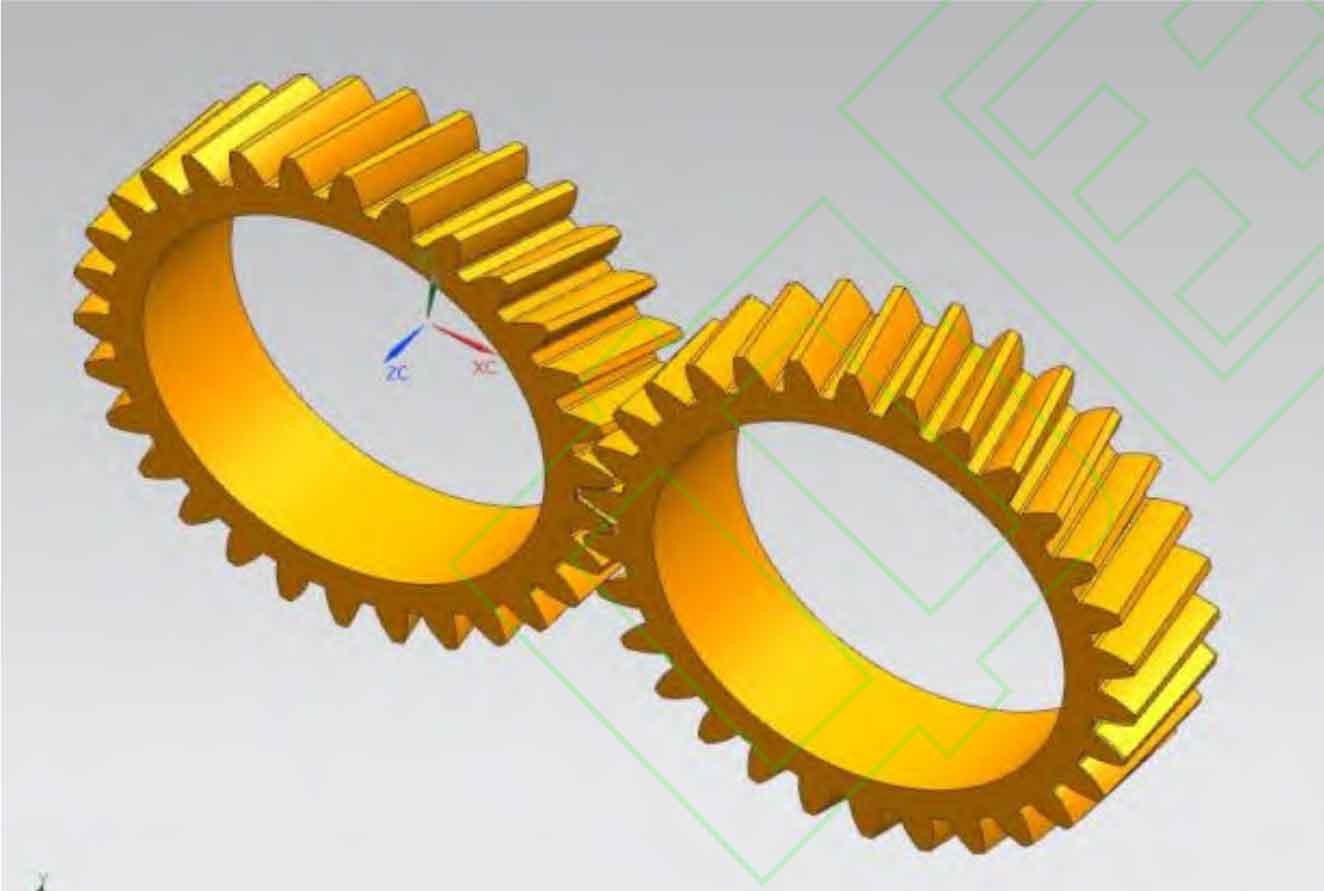

Taking a pair of helical gear pairs as the research object, the tooth surface equations of modified and standard helical gears are established in Mathematica based on the basic parameters and topological modification principles of helical gear pairs, and the tooth surface profiles of different modified parameters are obtained. The tooth surface is derived in the form of coordinate points, and three-dimensional solid modeling and assembly of helical gear pairs are performed in UG. The finite element method is used to simulate and analyze helical gear pairs with different modification parameters. Use ANSYS Workbench to conduct transient dynamic simulation analysis of the load carrying capacity of the modified helical gear pair, providing a theoretical basis for subsequent research on the dynamics of the modified helical gear.