In the field of oil extraction, traditional rod pump systems often face significant challenges, such as excessive energy consumption, low efficiency, and severe wear between rods and tubing, especially in deviated and cluster wells. These issues not only increase maintenance costs but also reduce the overall economic benefits of oil fields. To address these problems, we propose the use of a rack and pinion gear mechanism as a replacement for the conventional rod string. This approach aims to eliminate rod-tube eccentric wear and improve system reliability. In this article, we explore the application of rack and pinion gear in downhole oil production equipment through detailed static and dynamic analyses, including strength verification, finite element simulations, and kinetic modeling.

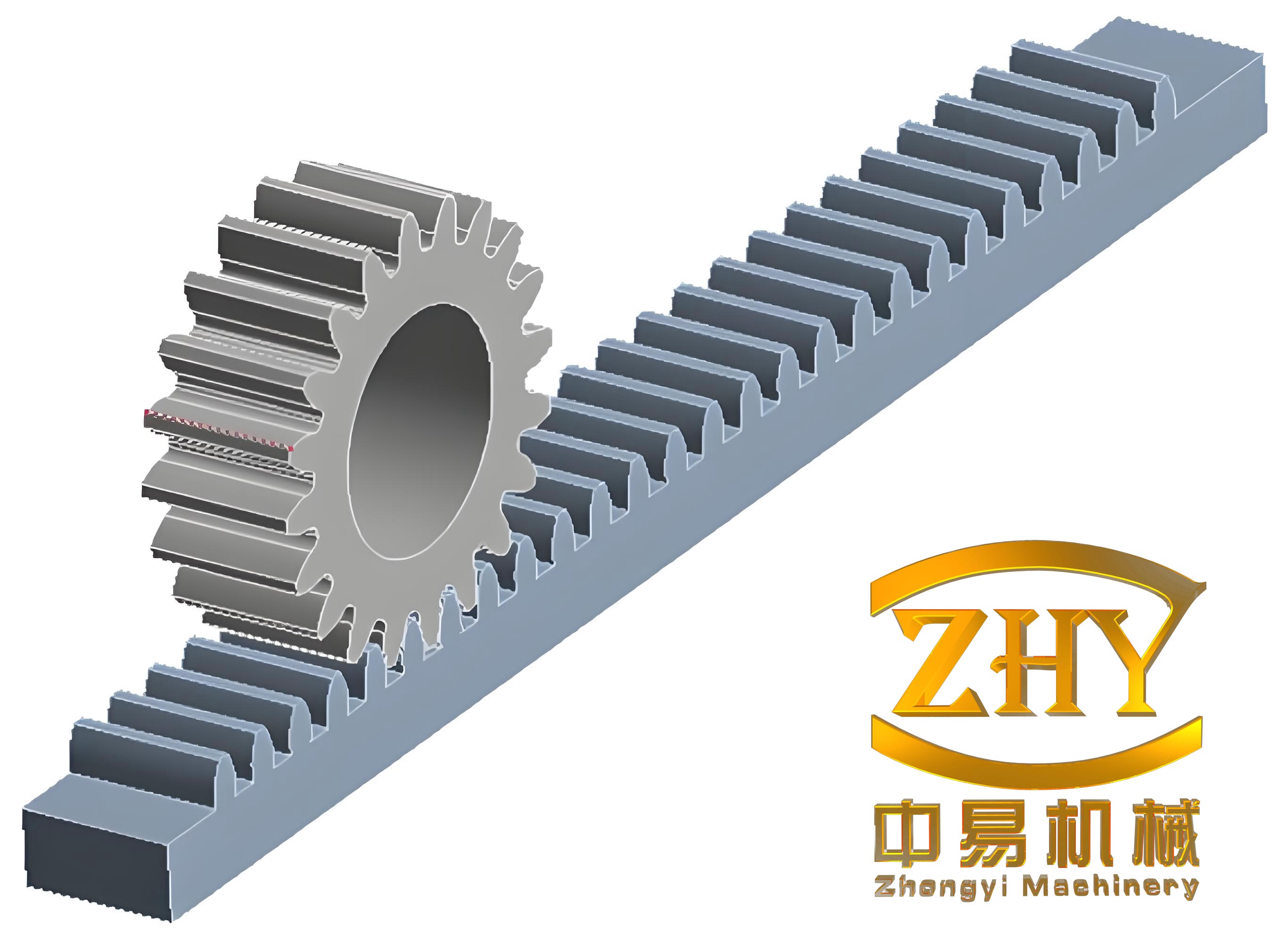

The rack and pinion mechanism is integrated into a downhole system driven by a submersible motor, which powers a reciprocating pump for artificial lift. The system comprises several key components: a submersible motor (including a protector), a gear reducer, a direction-changing mechanism, a bevel gear pair, and the rack and pinion gear assembly. The submersible motor receives power via a submersible cable, and the motion is transmitted through the reducer and direction-changing mechanism to the bevel gears, which convert horizontal rotation into vertical rotation. Finally, the rack and pinion gear transforms rotational motion into linear motion, driving the reciprocating pump. The direction-changing mechanism, consisting of an incomplete gear pair, enables forward and reverse rotation, while the bevel gears facilitate motion conversion in perpendicular planes. This setup ensures continuous oil extraction without the drawbacks of rod-based systems.

For the rack and pinion gear, we selected a standard involute spur gear made of 45 steel (forged), with key parameters summarized in Table 1. The rack and pinion gear design focuses on durability and efficiency, with a module of 2 mm, pressure angle of 20 degrees, and a pinion with 24 teeth. The pinion is driven by a 4 kW motor at 750 rpm, and the rack has a length of 1 meter to accommodate the stroke requirements. The theoretical daily production rate is 2.3 m³/d, based on a pump diameter of 32 mm, stroke of 1.4 m, and stroke frequency of 2 min⁻¹. These parameters ensure that the rack and pinion gear can handle the loads encountered in downhole environments.

| Parameter | Value |

|---|---|

| Pinion Drive Motor Power (kW) | 4 |

| Module (mm) | 2 |

| Pressure Angle (°) | 20 |

| Total Tooth Height (mm) | 4.5 |

| Pinion Tooth Width (mm) | 20 |

| Rack Tooth Width (mm) | 20 |

| Pinion Drive Motor Speed (rpm) | 750 |

| Number of Pinion Teeth | 24 |

| Rack Length (m) | 1 |

| Addendum Coefficient | 1 |

| Dedendum Coefficient | 0.25 |

In the static analysis phase, we first verified the strength of the rack and pinion gear to ensure it can withstand the operational loads. For hardened gear surfaces in closed transmission systems, the primary failure mode is tooth surface fatigue, so we focused on the contact fatigue strength. The allowable contact stress must satisfy the condition: $$ \sigma_H \leq [\sigma_H] $$ where $$ \sigma_H $$ is the calculated contact stress and $$ [\sigma_H] $$ is the allowable contact stress. Based on material properties for 45 steel, we set $$ [\sigma_H] \approx \sigma_{H \lim} = 523 \text{ MPa} $$. The contact stress is calculated using the formula: $$ \sigma_H = \sqrt{\frac{2K_H T_1}{\phi_d d_1^3}} \cdot Z_H Z_E Z_\epsilon $$ For the rack and pinion gear, the transmission ratio approaches infinity, simplifying the equation. Here, $$ K_H $$ is the load factor for contact fatigue, given by: $$ K_H = K_A K_V K_{H\alpha} K_{H\beta} $$ where $$ K_A $$ is the application factor, $$ K_V $$ is the dynamic factor, $$ K_{H\alpha} $$ is the transverse load factor, and $$ K_{H\beta} $$ is the face load factor. After substituting values from standard tables, we computed $$ \sigma_H = 495.155 \text{ MPa} $$, which is below the allowable limit, confirming the design’s adequacy.

To further validate the strength, we performed a finite element analysis (FEA) using ANSYS Workbench. We modeled the rack and pinion gear in a 3D CAD software, assuming a maximum of two tooth pairs in contact (i.e., contact ratio less than 2). The model was meshed with tetrahedral elements, and local refinements were applied at the contact areas, resulting in 335,345 nodes and 217,756 elements. Boundary conditions included fixed constraints on the pinion’s shaft hole and a 1000 N load on the rack’s end, with frictionless support at the rack’s base. The FEA results, as shown in Table 2, indicated a maximum contact stress of 478.94 MPa, slightly lower than the theoretical value due to real-world factors like material imperfections. The stress concentration occurred on the tooth surfaces, highlighting the need for surface protection in manufacturing and maintenance. The use of involute teeth with root fillets helped minimize stress risers, ensuring the rack and pinion gear meets design requirements.

| Parameter | Value |

|---|---|

| Maximum Contact Stress (MPa) | 478.94 |

| Nodes in Mesh | 335,345 |

| Elements in Mesh | 217,756 |

| Load Applied (N) | 1000 |

Moving to dynamic analysis, we developed a kinetic model of the rack and pinion gear system to study its behavior under operational conditions. The model treats the system as an elastic mechanical system with assumptions: both pinion and rack are linear elastic bodies; deformations of shafts and supports are negligible; damping is viscous; and tooth friction is ignored. The pinion has a base circle radius $$ r_{b1} $$, and the tooth pair is represented by a spring with stiffness $$ k_v $$, which is the comprehensive meshing stiffness. The model also accounts for tooth profile errors $$ e $$ and meshing damping coefficient $$ c_v $$. The equations of motion are derived from force balance. The comprehensive meshing deformation $$ \delta_i $$ for up to two tooth pairs is: $$ \delta_i = \theta r_{b1} – e_i – s $$ where $$ \theta $$ is the pinion’s rotation angle, and $$ s $$ is the rack’s displacement. The meshing force $$ F $$ is: $$ F = \sum_{i} F_i = \sum_{i} (k_{vi} \delta_i + c_{vi} \dot{\delta_i}) = \sum_{i} [k_{vi} (\theta r_{b1} – s – e_i) + c_{vi} (\dot{\theta} r_{b1} – \dot{s} – \dot{e_i})] $$ The torque balance equations are: $$ J \ddot{\theta} = T – r_{b1} F $$ $$ m \ddot{s} = -G + F \cos \alpha $$ where $$ J $$ is the pinion’s moment of inertia, $$ T $$ is the driving torque, $$ m $$ is the rack’s mass, $$ G $$ is the rack’s weight, and $$ \alpha $$ is the pressure angle (20° for standard gears). Combining these, we get: $$ J \ddot{\theta} + r_{b1} \sum_{i} [k_{vi} (\theta r_{b1} – s – e_i) + c_{vi} (\dot{\theta} r_{b1} – \dot{s} – \dot{e_i})] = T $$ $$ m \ddot{s} – \cos \alpha \sum_{i} [k_{vi} (\theta r_{b1} – s – e_i) + c_{vi} (\dot{\theta} r_{b1} – \dot{s} – \dot{e_i})] = -G $$ These equations show that the time-varying meshing stiffness induces dynamic contact forces, leading to vibrations that can affect system stability and lifespan.

For dynamic simulation, we used ADAMS software to model the rack and pinion gear system. The 3D model was imported, and constraints were applied: a revolute joint on the pinion, a translational joint on the rack, and a gear pair constraint between them. A variable torque was applied to the pinion to simulate the direction-changing mechanism, and a horizontal load on the rack represented the pump and fluid weights. The contact force was computed using the Impact function: $$ F_{\text{impact}} = K(q_0 – q)^f – C \frac{dq}{dt} \text{STEP}(q, q_0 – j, q_0, 0) $$ where $$ K $$ is the contact stiffness, calculated as: $$ K = \frac{4}{3} \left( \frac{R_1 R_2}{R_1 + R_2} \right)^{1/2} \cdot \frac{E_1 E_2}{(1 – \gamma_1^2) E_2 + (1 – \gamma_2^2) E_1} $$ Here, $$ R_1 $$ and $$ R_2 $$ are the radii of curvature at the contact point, $$ E_1 $$ and $$ E_2 $$ are elastic moduli, and $$ \gamma_1 $$ and $$ \gamma_2 $$ are Poisson’s ratios. With parameters for steel, we obtained $$ K = 7.51 \times 10^5 \text{ N/m}^{3/2} $$. The simulation results over a 30-second cycle, as summarized in Table 3, show the rack’s acceleration, velocity, displacement, and dynamic contact force. The acceleration curve exhibited fluctuations due to inertial loads, while the velocity profile indicated uniform acceleration, steady motion, and deceleration phases, corresponding to torque reversals. The maximum displacement was 1.3 m, close to the theoretical stroke of 1.4 m, and the contact force displayed periodic oscillations from inertial impacts during direction changes. Although these vibrations are within acceptable limits, they highlight the need for further optimization to reduce dynamic effects in the rack and pinion gear system.

| Parameter | Value |

|---|---|

| Maximum Rack Displacement (m) | 1.3 |

| Simulation Cycle (s) | 30 |

| Contact Force Fluctuation | Periodic oscillations |

| Acceleration Profile | Fluctuations due to inertia |

In conclusion, the application of rack and pinion gear in downhole oil production equipment offers a viable solution to overcome the limitations of rod-based systems, particularly in preventing rod-tube wear. Through static analysis, we confirmed that the rack and pinion gear meets strength requirements, with theoretical and FEA results aligning closely. Dynamic simulations revealed that the system operates effectively but experiences periodic vibrations and inertial loads during direction changes. These findings validate the feasibility of using rack and pinion gear in such environments, though additional research is needed to mitigate vibration impacts. Overall, the rack and pinion mechanism demonstrates promise for enhancing the efficiency and durability of oil extraction processes.