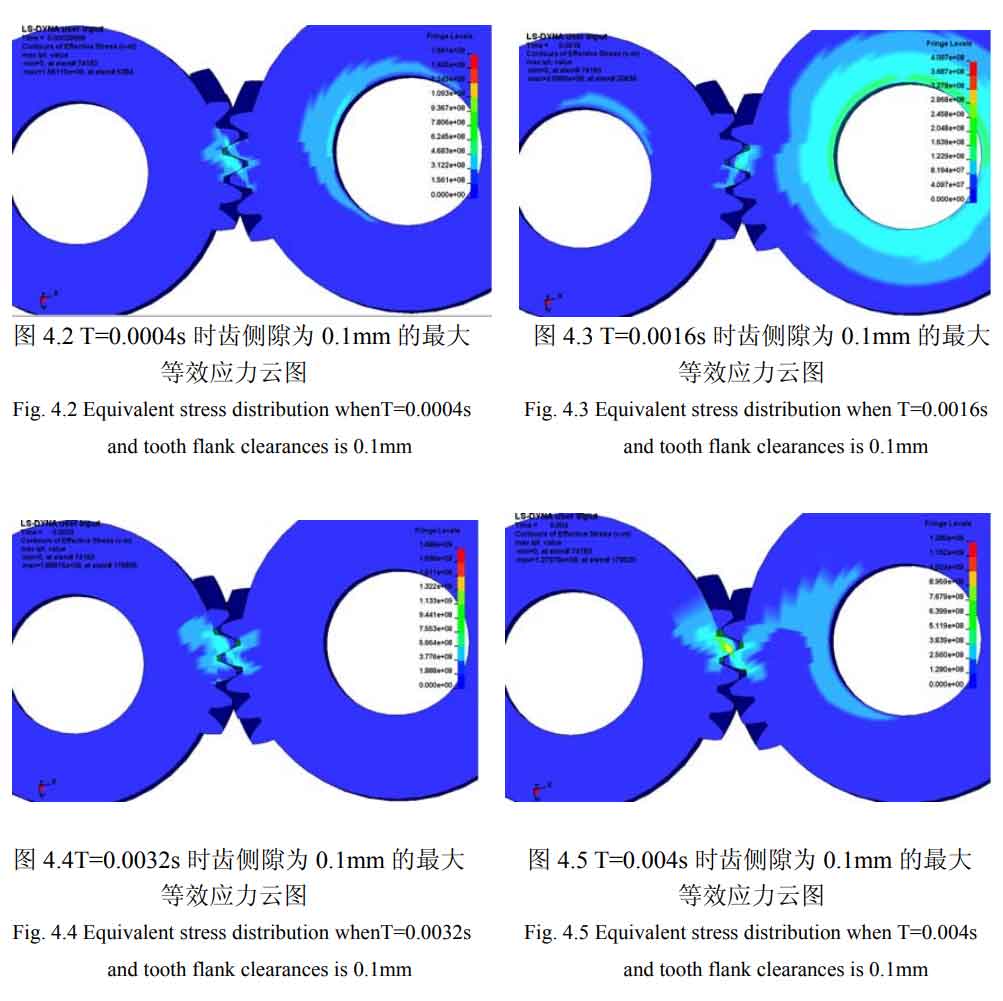

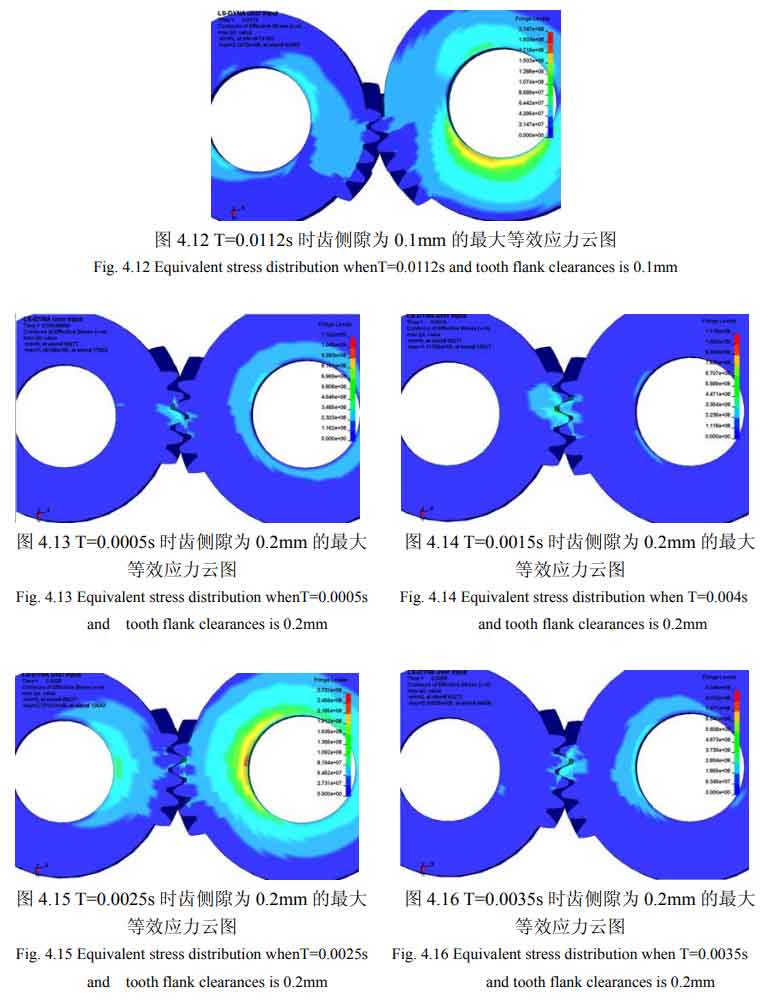

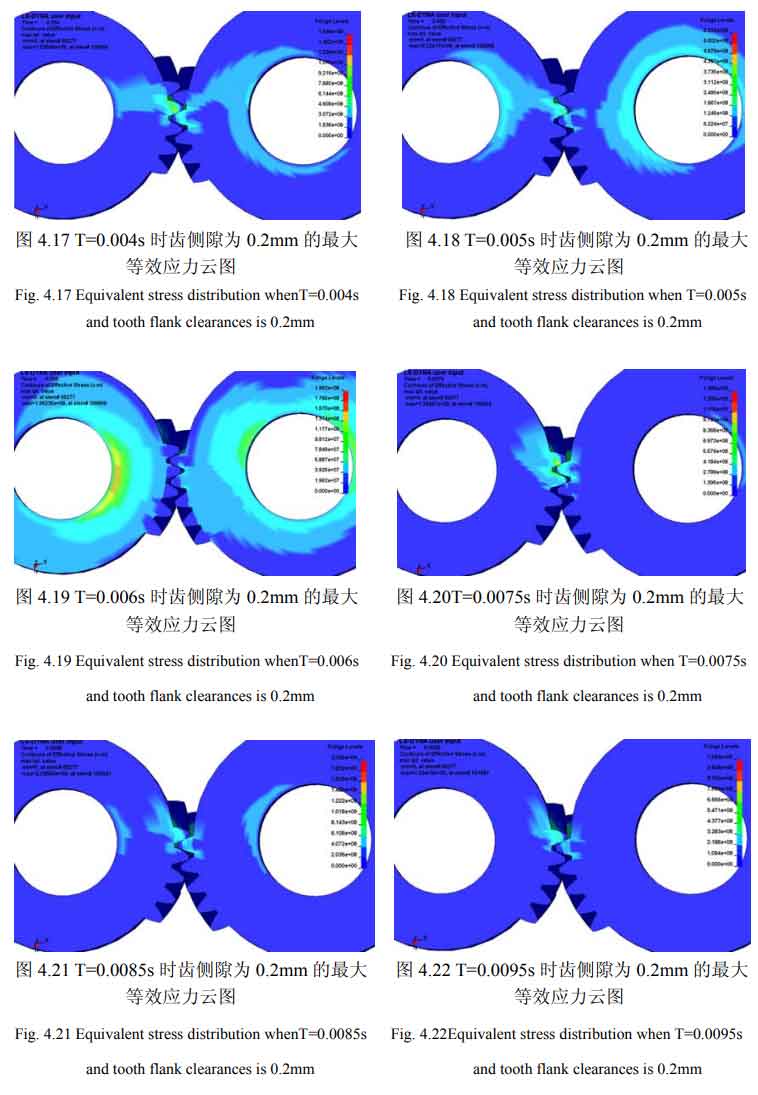

According to the structural parameters of the fourth gear helical gear pair of a heavy truck transmission studied, the dynamic contact stresses of the helical gear pair with backlash of 0.1mm, 0.2mm and 0.3mm are calculated by finite element method. Figure 1-2 shows the variation curves of the maximum equivalent stress of the driving and driven gears with backlash of 0.1mm, 0.2mm and 0.3mm respectively. The maximum equivalent stress of helical gear pairs with different backlash during meshing is shown in the table.

| 0.1mm | 0.2mm | 0.3mm | |

| Maximum equivalent stress of driving wheel / MPa | 1896 | 2324 | 2757 |

| Maximum equivalent stress of driven wheel / MPa | 1888 | 2385 | 2428 |

Fig. 1-fig. 33 are the equivalent stress nephogram of helical gear pair under different backlash. From the stress nephogram, it can be seen that the fluctuation of contact stress increases with the increase of backlash; At the same time, it can be seen from the table that with the increase of backlash, the impact stress on the meshing surface of driving and driven wheels increases accordingly.

This is because with the increase of backlash, the impact vibration of helical gear pair increases in the meshing process, resulting in the contact stress and stress fluctuation of helical gear increase with the increase of backlash.