When shearer cuts coal, the rocker box will produce complex three-dimensional dynamic deformation under the joint action of internal and external excitation, which changes the meshing state of internal multi-stage gear transmission; the change of meshing state in turn affects the internal excitation of rocker box. Therefore, the dynamic response of multi-stage gear transmission and rocker box is coupled with each other. Taking the rated working condition as the simulation condition, the coupling response characteristics of multi-stage gear transmission and rocker box are analyzed. For the roller load under rated condition, the load fluctuation coefficient is 0.2.

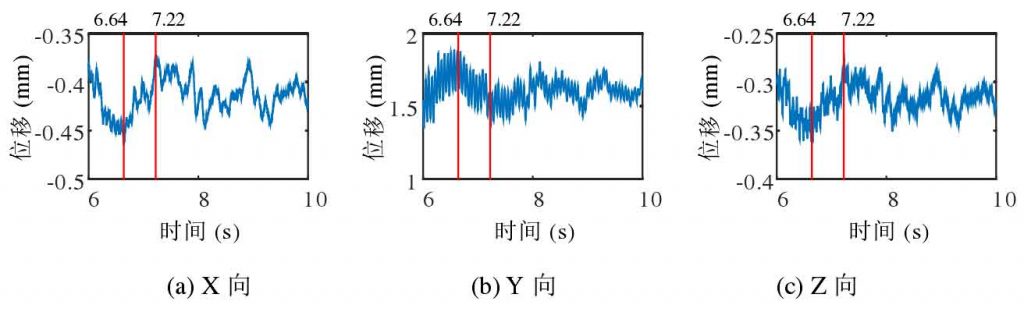

The dynamic deformation of rocker box under the combined action of internal and external excitation is analyzed, and the meshing state change of internal multi-stage gear transmission after the deformation of rocker box is analyzed. As shown in Figure 1, there are 17 shaft / bearing holes on the rocker arm box, numbered BP1 ~ bp17 from the motor end to the roller end. Bp17 is the center of the bearing hole on the rocker arm housing, which is located at the free end of the rocker arm housing. It roughly represents the maximum displacement of the shaft / bearing hole deformation on the rocker arm housing. Figure 2 shows the deformation displacement components of bp17 in three directions. Since the system has not reached steady state at the beginning of simulation, the dynamic response contains damped free vibration related to initial value and decaying with time, so the curve in the figure starts from 6 seconds. According to the statistics in Figure 2, the deformation displacement of bp17 is as follows:

The peak value is 3.29 mm, and the average value is 1.62 mm. Figure 3 (a) and (b) show the dynamic displacement of the cutting part in 6.64 seconds and 7.22 seconds respectively (displayed deformation: actual deformation = 1000:1). It can be seen from the figure that the overall deformation posture of the cutting part is similar to that of the cantilever beam, and the absolute deformation displacement increases gradually from the motor end to the roller end. Affected by the deformation of rocker box, the gear center distance and parallelism are not ideal.