As the end of the gear transmission chain, the load of each accessory directly affects the strength, connection reliability, lubrication and other dynamic characteristics of the gear system. During the working process, affected by the working state and actual working demand, the load of the water pump, fuel injection pump, oil pump and other loads in the gear system are constantly changing. Take the gear system driving the fuel injection pump as an example to study the impact of the load on the gear system. According to the measured load curve of the fuel injection pump provided by the manufacturer, Considering the actual working conditions, the dynamic response of the gear system under 100%, 105%, 110%, 115% and 120% fuel injection pump load is studied.

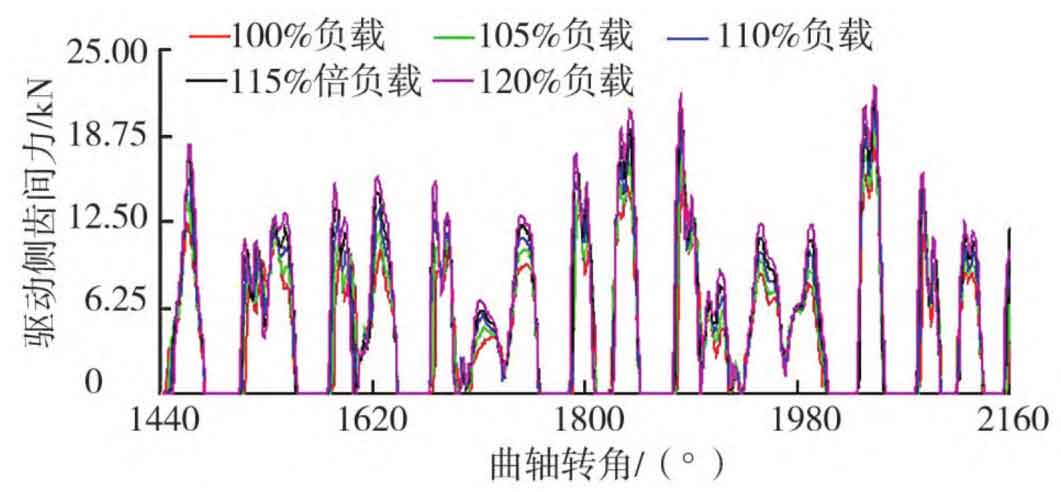

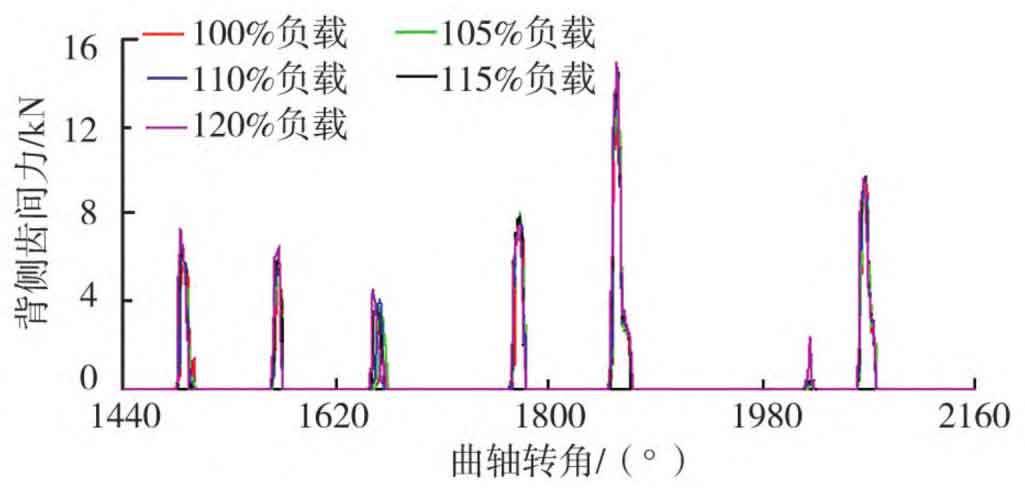

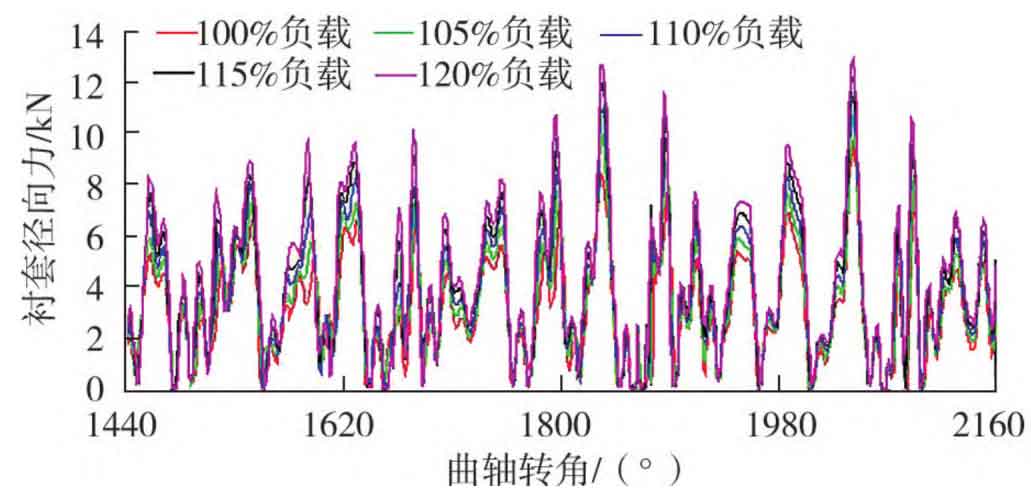

The force between the teeth on the drive side, the force between the teeth on the back side and the radial force of the bushing under different fuel injection pump loads are shown in Figures 1-3.

It can be seen from Figures 1 to 3 that when the fuel injection pump is loaded at 100%, 105%, 110%, 115% and 120%, the maximum inter-tooth force at the driving side is 18103 7、19 120. 9、20 485. 5、21 559. 4、22 345. 4N, the maximum back interdental force is 12488 0、 13 313. 2、14 119. 0、14 602. 3、15 004. 0N, the maximum bushing radial force is 9782 7、10 615. 7、11 441. 7、12 233. 2、12 868. 2 N; The change of load has a significant impact on the force between the teeth on the driving side and the force between the teeth on the back side. The peak value of the force between the teeth increases with the increase of load, and the change is obvious. In the case of large load, the change of the force between the teeth is more uneven; The load change has a significant impact on the radial force of the bushing, which directly affects the connection reliability of the gear.

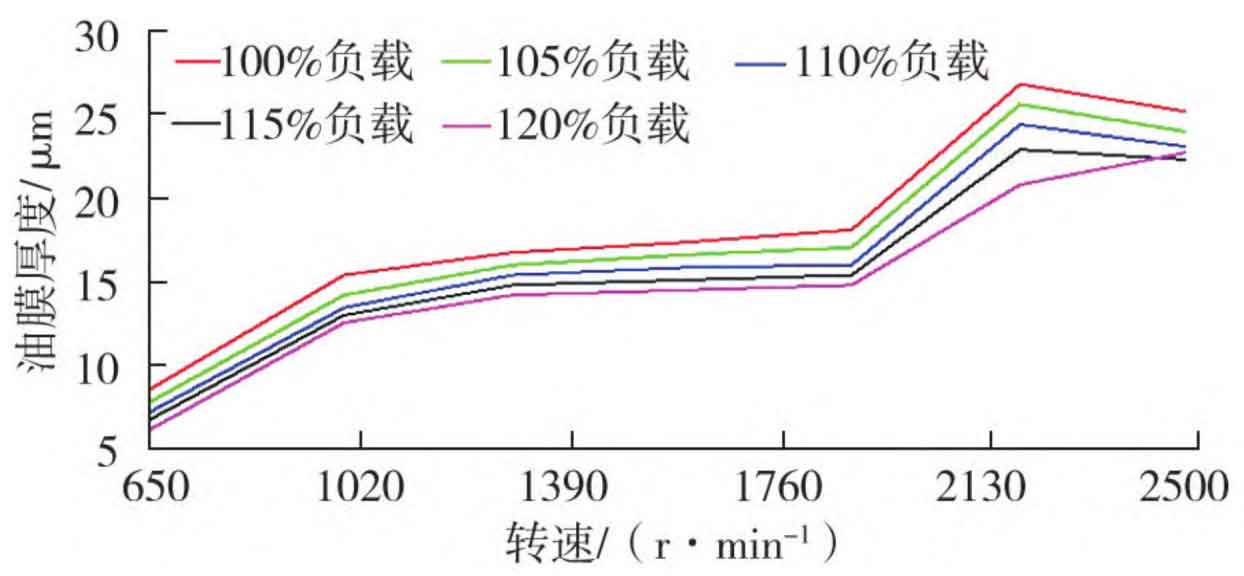

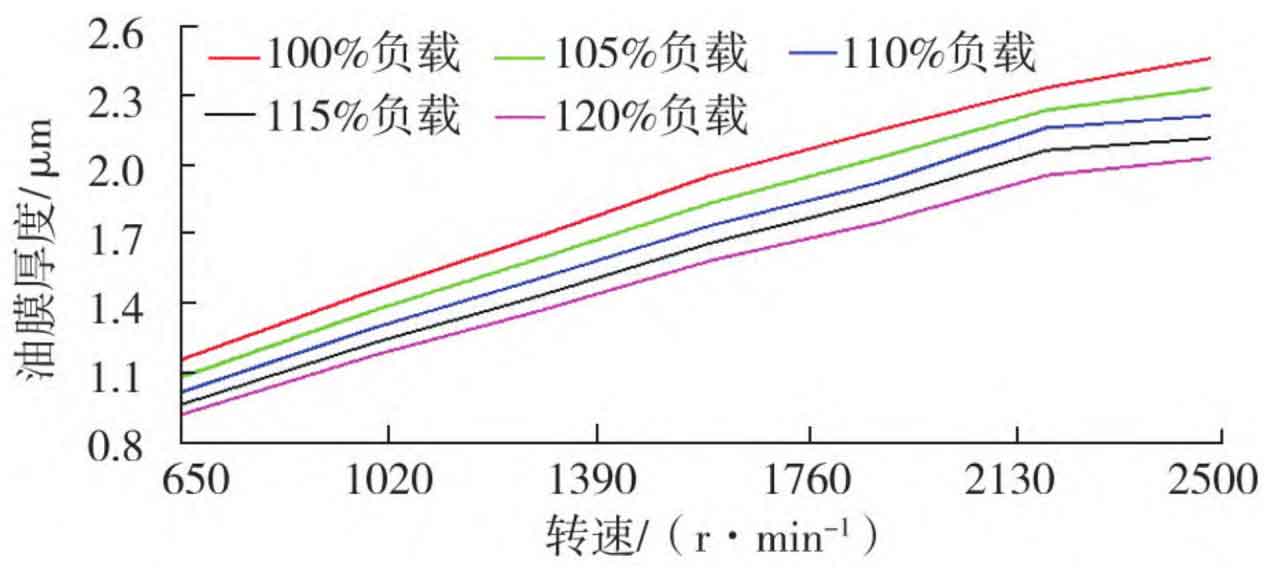

When the fuel injection pump loads are different, the oil film thickness of camshaft gear bushing and the oil film thickness of fuel injection pump idler gear bushing change as shown in Figures 4 and 5. It can be seen from Fig. 4 and Fig. 5 that with the increase of load, the oil film thickness of the bushing and the oil film thickness of the idler gear bushing of the injection pump gradually decrease, and the oil film thickness of the bushing is approximately linear with the load at a certain speed. When the load variation range increases, the change of the oil film thickness of the bushing tends to be slow.

To sum up, even if the load change of the fuel injection pump is small, the impact on the main dynamic characteristics of the whole transmission chain is also significant. Therefore, when lifting the dynamic indicators of the gear system, in addition to the optimization of the gear system itself, the reasonable optimization and matching of all accessories to reduce the dynamic load can indirectly improve the dynamic characteristics of the gear system.