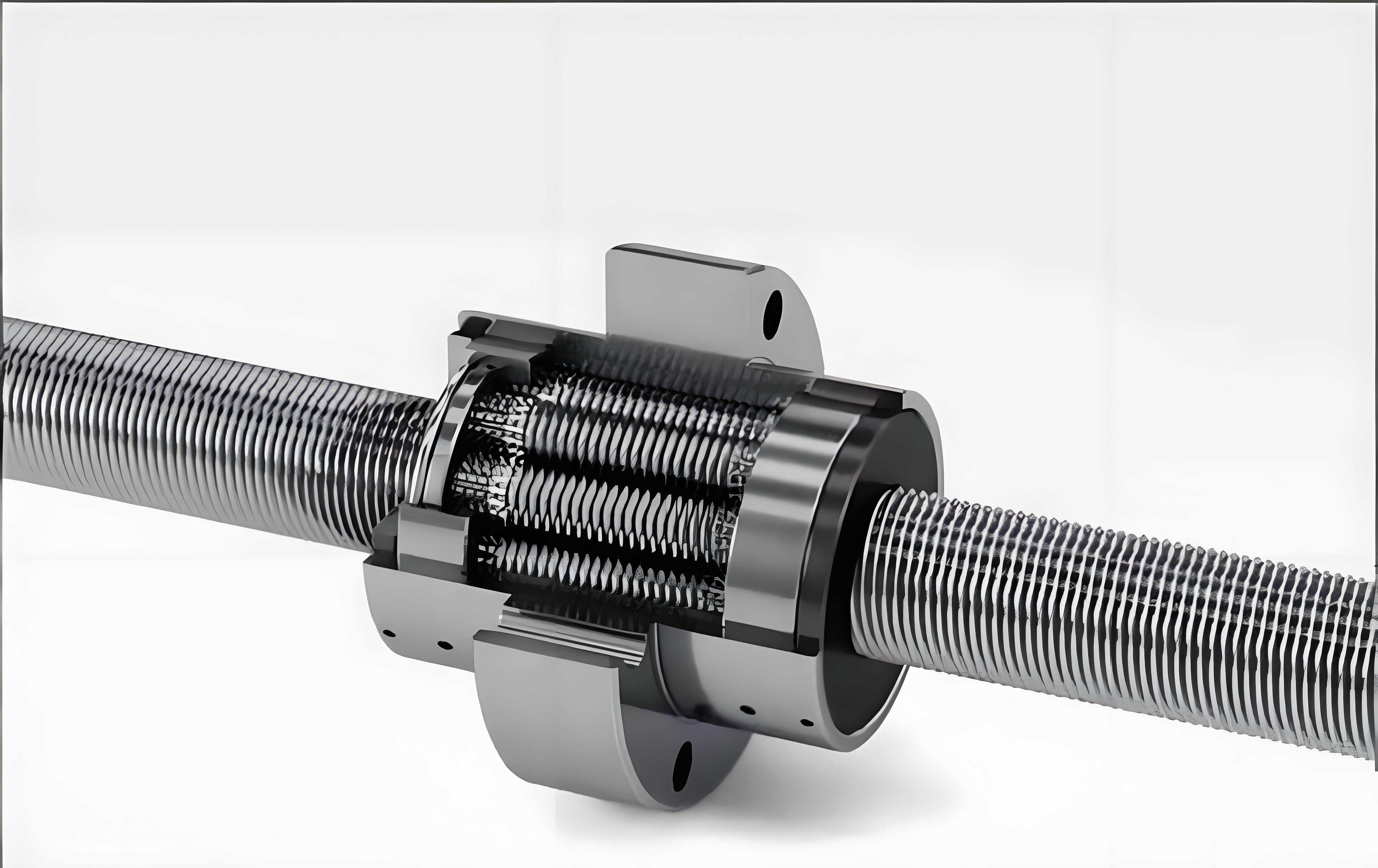

In the field of precision mechanical transmission, the planetary roller screw assembly stands out as a critical component for converting rotational motion into linear motion with high efficiency, load capacity, and accuracy. Its applications span across aerospace, precision machine tools, packaging, energy, and special equipment, where high-speed and high-precision performance are paramount. However, under high-speed operating conditions, the planetary roller screw assembly is subjected not only to axial loads but also to significant inertial forces, which dramatically alter the contact forces and load distribution between the rollers, screw, and nut. Understanding and modeling these dynamic effects is essential for optimizing the performance and reliability of the planetary roller screw assembly. In this article, I present a comprehensive study on the dynamic load distribution calculation method for the thread pair of a planetary roller screw assembly, incorporating inertial forces and validating the model through finite element analysis.

The core of this work lies in developing a theoretical model that accounts for the static and dynamic contact forces within the planetary roller screw assembly. Traditionally, load distribution studies have focused on static conditions, neglecting the inertial forces that arise during high-speed operation. Here, I start by establishing the static contact force calculations based on helical surface equations and deformation coordination relationships. Then, I extend the model to include inertial forces, deriving the dynamic contact forces and load distribution along the threads. The model is verified against finite element simulations, and a parametric analysis is conducted to investigate the influence of key operational and geometric parameters. Throughout this discussion, the term “planetary roller screw assembly” will be frequently emphasized to underscore its centrality in this research.

To begin, let’s consider the fundamental geometry and kinematics of the planetary roller screw assembly. The assembly consists of a central screw, multiple rollers arranged planetary-style, and a nut. The threads on these components engage in a complex helical contact, where load distribution is inherently non-uniform due to elastic deformations. Under static conditions, the contact forces between the roller-screw and roller-nut pairs can be derived from the normal vectors at the contact points. For the roller-screw side, the static contact force vector \(\mathbf{F}^s_{SR}\) is expressed as:

$$

\mathbf{F}^s_{SR} = \frac{F^s_{SR}}{\sqrt{1 + \tan^2 \lambda_{SR} + \tan^2 \beta_{SR}}} \begin{bmatrix} \cos \phi_{SR} \tan \beta_{SR} – \sin \phi_{SR} \tan \lambda_{SR} \\ -\sin \phi_{SR} \tan \beta_{SR} – \cos \phi_{SR} \tan \lambda_{SR} \\ -1 \end{bmatrix}

$$

where \(F^s_{SR}\) is the magnitude of the static contact force, given by:

$$

F^s_{SR} = \frac{F_{NZ}}{n_{\text{roller}}} \cdot \sqrt{1 + \tan^2 \lambda_{SR} + \tan^2 \beta_{SR}}

$$

Here, \(F_{NZ}\) is the axial load on the nut, \(n_{\text{roller}}\) is the number of rollers, \(\lambda_{SR}\) is the lead angle at the roller-screw contact point, \(\beta_{SR}\) is the thread flank angle, and \(\phi_{SR}\) is the engagement offset angle. The lead angle and flank angle are computed from the geometry:

$$

\tan \lambda_{SR} = \frac{L_R}{2\pi r_{SR}}, \quad \tan \beta_{SR} = \frac{r_{SR} – r_R – u_{TR}}{\sqrt{r_{TR}^2 – (r_{SR} – r_R – u_{TR})^2}}

$$

with \(L_R\) as the roller lead, \(r_{SR}\) as the engagement radius, \(r_R\) as the nominal roller radius, \(r_{TR}\) as the thread profile radius, and \(u_{TR}\) as the coordinate of the profile center. Similarly, for the roller-nut side, the static contact force \(\mathbf{F}^s_{NR}\) is:

$$

\mathbf{F}^s_{NR} = \frac{F^s_{NR}}{\sqrt{1 + \tan^2 \lambda_R + \tan^2 \beta_R}} \begin{bmatrix} -\tan \beta_R \\ -\tan \lambda_R \\ 1 \end{bmatrix}

$$

where \(F^s_{NR} = \frac{F_{NZ}}{n_{\text{roller}}} \cdot \sqrt{1 + \tan^2 \lambda_R + \tan^2 \beta_R}\), and \(\lambda_R\) and \(\beta_R\) are the lead and flank angles for the roller (same as nut). These equations assume load uniformity among rollers and elastic deformations only, which is standard for static analysis of a planetary roller screw assembly.

However, under high-speed operation, the planetary roller screw assembly experiences inertial forces due to the planetary motion of the rollers around the screw. This inertial force \(F_c\) acts radially outward and is given by:

$$

F_c = m_r \omega_P^2 r

$$

where \(m_r\) is the roller mass, \(\omega_P\) is the orbital angular velocity of the roller, and \(r\) is the pitch radius. To incorporate this into the load distribution model, I consider the force equilibrium on a roller. The dynamic contact forces \(F_{SR}\) (roller-screw) and \(F_{NR}\) (roller-nut) must balance the inertial force. From the radial and axial equilibrium equations:

$$

F_{SR} \sin \alpha_{SR} + F_{NR} \sin \alpha_{NR} = 0

$$

$$

F_{SR} \cos \alpha_{SR} + F_{NR} \cos \alpha_{NR} + F_c = 0

$$

Here, \(\alpha_{SR}\) and \(\alpha_{NR}\) are the contact angles after deformation, which differ from the initial contact angles \(\alpha^0_{SR}\) and \(\alpha^0_{NR}\) due to Hertzian contact deformations \(\delta_{SR}\) and \(\delta_{NR}\). The relationship between the contact angles and deformations is derived from geometric compatibility:

$$

\cos \alpha_{SR} = \frac{(r_S + r_N – 2r_R) \cos \alpha^0_{SR}}{r_S + r_N – 2r_R + 2\delta_{SR}}

$$

$$

\cos \alpha_{NR} = \frac{(r_S + r_N – 2r_R) \cos \alpha^0_{NR}}{r_S + r_N – 2r_R + 2\delta_{NR}}

$$

where \(r_S\) and \(r_N\) are the nominal radii of the screw and nut, respectively. The contact deformations themselves are computed using Hertzian theory:

$$

\delta_{XR} = \delta^* \left( \frac{3F_{XR}}{2\sum \rho} \right)^{2/3} \left( \frac{1-\mu_R^2}{E_R} + \frac{1-\mu_X^2}{E_X} \right)^{2/3} \left( \sum \rho \right)^{1/3}

$$

with \(X\) denoting \(S\) or \(N\), \(\delta^*\) as a Hertzian coefficient, \(\sum \rho\) as the sum of curvatures, and \(E\), \(\mu\) as elastic moduli and Poisson’s ratios. This forms a coupled system that requires iterative solution to find the dynamic contact forces in the planetary roller screw assembly.

To model the load distribution along the threads, I account for three types of deformations: shaft segment deformation, thread tooth deformation, and contact point deformation. Each contributes to the overall compliance of the planetary roller screw assembly. For the \(i\)-th thread pair, the deformation compatibility between the nut and roller sides yields:

$$

\sum l_{Ni} = \sum l_{Ri}

$$

where \(\sum l_{Ni}\) and \(\sum l_{Ri}\) represent the total deformations on the nut and roller sides, respectively, including shaft, tooth, and contact deformations. Expressing these in terms of stiffnesses:

$$

\sum_{j=1}^{i} \frac{F_{NRj}}{k_{NB}} + \frac{F_{NRi} – F_{NRi+1}}{k_{NT}} + \frac{F_{NRCi}}{k_{NRC}} = \sum_{j=0}^{\lfloor i/2 \rfloor} \frac{(F_{NRj} – F_{SRj}) + F_{NR(\lfloor i/2 \rfloor+1)}}{k_{RB}} + \frac{F_{NRi+1} – F_{NRi}}{k_{RT}} + \frac{F_{NRCi+1}}{k_{NRC}}

$$

and similarly for the roller-screw side:

$$

\sum_{j=1}^{n} \frac{F_{SRj} – \sum_{j=1}^{i} F_{SRj}}{k_{SB}} + \frac{F_{SRi+1} – F_{SRi}}{k_{ST}} + \frac{F_{SRi+1}}{k_{SRC}} = \frac{2\sum_{j=0}^{\lfloor i/2 \rfloor} (F_{NRj} – F_{SRj}) + F_{NR(\lfloor i/2 \rfloor+1)}}{k_{RB}} + \frac{F_{SRi} – F_{SRi+1}}{k_{RT}} + \frac{F_{SRj}}{k_{SRC}}

$$

Here, \(k_{NB}\), \(k_{NT}\), \(k_{NRC}\) are the nut shaft, tooth, and contact stiffnesses, and similarly for the roller and screw. The contact forces per thread \(F_{XRi}\) must sum to the overall dynamic contact forces \(F_{XR}\). Solving this system of equations provides the dynamic load distribution along the threads of the planetary roller screw assembly.

To validate the theoretical model, I compare it with finite element analysis (FEA) simulations. The FEA model is built with simplified geometry (three rollers instead of ten for computational efficiency) and meshed with tetrahedral elements. Contact pairs are defined between the roller-screw and roller-nut threads, and inertial forces are applied. The material is GCr15 steel with standard properties. Below is a table summarizing the key parameters used in the validation:

| Component | Nominal Radius \(r\) (mm) | Flank Angle \(\beta\) (°) | Pitch \(P\) (mm) | Number of Threads | Elastic Modulus \(E\) (GPa) | Poisson’s Ratio \(\mu\) |

|---|---|---|---|---|---|---|

| Roller | 4 | 45 | 2 | 20 | 212 | 0.29 |

| Screw | 12 | 45 | 2 | 5 | 212 | 0.29 |

| Nut | 20 | 45 | 2 | 1 | 212 | 0.29 |

| Parameter | Value |

|---|---|

| Roller mass \(m_r\) (kg) | 0.032 |

| Screw speed \(\omega_S\) (rad/s) | 83 |

| Axial load \(F_{NZ}\) (N) | 5000 |

| Roller lead \(L_R\) (mm) | 2 |

| Number of rollers \(n_{\text{roller}}\) | 10 |

| Number of threads per roller \(z\) | 20 |

For a screw speed of 83 rad/s, the theoretical model predicts dynamic contact forces of \(F_{SR} = 705.51 \, \text{N}\) and \(F_{NR} = 758.48 \, \text{N}\). The FEA results show mean values of \(F_{SR} = 683 \, \text{N}\) and \(F_{NR} = 734 \, \text{N}\), with a relative error below 5%. This close agreement validates the accuracy of the dynamic load distribution model for the planetary roller screw assembly. The load distribution along the threads also matches well: on the roller-screw side, the force decreases with thread序号, while on the roller-nut side, it increases, and the non-uniformity is more pronounced on the roller-screw side. The FEA results exhibit slight fluctuations due to radial displacements, but the overall trend confirms the theoretical predictions.

With the model validated, I proceed to analyze the influence of various parameters on the dynamic load distribution in the planetary roller screw assembly. The parameters include screw speed, axial load, pitch, and flank angle. Each parameter is varied while others are held constant, and the resulting load distributions are computed.

Effect of Screw Speed: The screw speed \(\omega_S\) is varied from 26 to 133 rad/s, corresponding to roller orbital speeds of 10 to 50 rad/s. The axial load is fixed at 5000 N. The dynamic contact forces and load distributions change significantly with speed. As speed increases, the inertial force \(F_c\) rises, causing the roller to shift toward the nut and away from the screw. This reduces the roller-screw contact force \(F_{SR}\) and increases the roller-nut contact force \(F_{NR}\). The non-uniformity of load distribution along the threads also intensifies with speed, particularly on the roller-screw side. This highlights the critical role of speed in the design of a high-speed planetary roller screw assembly.

Effect of Axial Load: The axial load \(F_{NZ}\) is varied from 0 to 6000 N at a constant screw speed of 83 rad/s. As expected, both \(F_{SR}\) and \(F_{NR}\) increase linearly with load. However, the load distribution becomes more uneven at higher loads, with the roller-screw side showing greater non-uniformity than the roller-nut side. This implies that under heavy loads, the planetary roller screw assembly may experience localized stress concentrations, necessitating careful thread design.

Effect of Pitch: The pitch \(P\) is set to 2, 4, and 6 mm, with other parameters constant. Larger pitch values lead to steeper load distribution curves, indicating increased non-uniformity. This is because a larger pitch alters the lead angles and contact geometry, amplifying the deformation differences along the threads. Thus, for a planetary roller screw assembly intended for high-speed applications, a smaller pitch may be preferable to ensure smoother load distribution.

Effect of Flank Angle: The flank angle \(\beta\) is varied from 40° to 50°. Contrary to pitch, a larger flank angle results in flatter load distribution curves, reducing non-uniformity. This is due to improved load sharing across thread teeth as the contact area changes. Therefore, optimizing the flank angle can enhance the dynamic performance of the planetary roller screw assembly.

To summarize these effects quantitatively, consider the following table showing the trends in dynamic load non-uniformity (represented by the slope of load distribution curves) for each parameter:

| Parameter | Range | Effect on Non-uniformity | Impact on Planetary Roller Screw Assembly |

|---|---|---|---|

| Screw speed \(\omega_S\) | 26–133 rad/s | Increases | Higher inertial forces worsen load distribution |

| Axial load \(F_{NZ}\) | 0–6000 N | Increases | Heavier loads amplify unevenness, especially on screw side |

| Pitch \(P\) | 2–6 mm | Increases | Larger pitch leads to steeper distribution |

| Flank angle \(\beta\) | 40°–50° | Decreases | Larger angle improves load sharing |

The mathematical expressions for these trends can be derived from the model. For instance, the inertial force dependency is explicit: \(F_c \propto \omega_P^2\), and since \(\omega_P\) is proportional to \(\omega_S\), we have \(F_c \propto \omega_S^2\). This quadratic relationship explains why speed has a strong impact on the planetary roller screw assembly. Similarly, the contact deformations \(\delta_{XR} \propto F_{XR}^{2/3}\), linking axial load to non-linearity in load distribution.

In conclusion, the dynamic load distribution in a planetary roller screw assembly is a complex interplay of static contact forces, inertial effects, and thread deformations. The theoretical model developed here successfully incorporates these factors, providing accurate predictions validated by FEA. Key findings include: (1) inertial forces cause the roller to move toward the nut, reducing roller-screw contact forces and increasing roller-nut forces; (2) load distribution non-uniformity escalates with screw speed and axial load, while larger flank angles mitigate it, and larger pitch exacerbates it. These insights are crucial for designing planetary roller screw assemblies for high-speed applications, where dynamic effects cannot be ignored. Future work could explore thermal effects, wear, or more complex roller configurations to further advance the understanding of this vital transmission component.

Throughout this analysis, the importance of the planetary roller screw assembly in modern machinery is evident, and the dynamic load distribution model presented here offers a robust tool for its optimization. By repeatedly considering the planetary roller screw assembly in various contexts, from static calculations to high-speed dynamics, I hope to emphasize its significance and the need for continued research in this area.