Abstract

This paper aims to investigate the dynamic meshing behavior and fatigue life of high-speed helical gear. Initially, a multi-degree-of-freedom rotor-bearing system dynamic equation is established using the finite element method to calculate the natural frequency of gear meshing. Subsequently, the displacement response is computed using the Newmark-β method. The tooth profiles are modified in both the profile and lead directions using KISSsoft, and transient analyses of helical gear pairs before and after modification are performed in ANSYS Workbench. A comparative analysis focusing on equivalent stress, fatigue life, and safety factor is conducted. The results demonstrate that modified helical gear exhibit reduced equivalent stress, increased fatigue life, and improved safety factors, thereby validating the feasibility of the modification approach and providing a valuable reference for high-speed helical gear meshing research.

1. Introduction

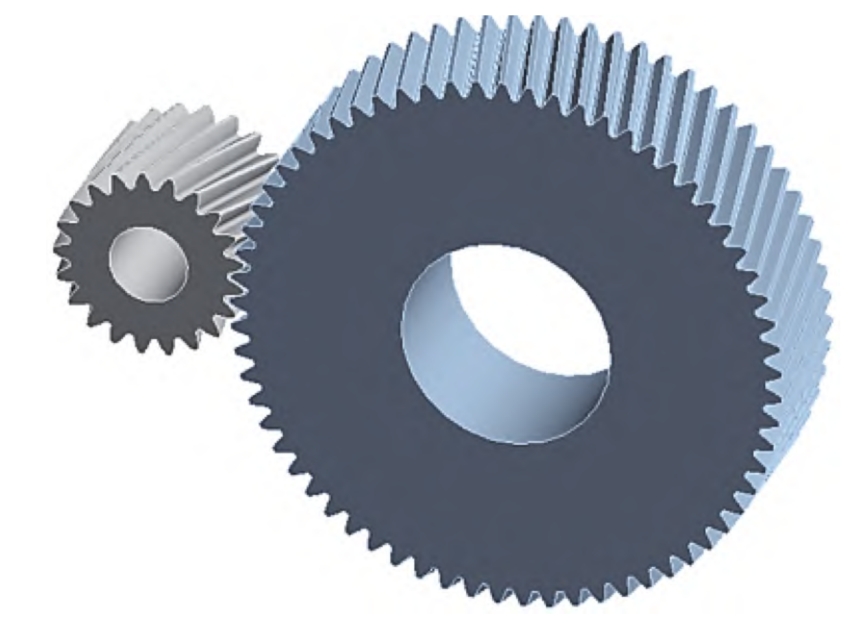

Helical gear is widely utilized in various industrial applications, particularly in electric vehicles, due to their smooth transmission, high load-bearing capacity, and wide range of applicability. However, prolonged use of gears can lead to issues such as vibration during transmission, significantly impacting transmission efficiency, and fatigue failure under heavy loads and high speeds. Therefore, an in-depth study of helical gear is essential to address these challenges and enhance gear performance.

This paper presents a comprehensive approach to analyze the dynamic meshing and fatigue life of high-speed helical gear. By combining theoretical modeling, simulation, and empirical analysis, we aim to identify effective gear modification strategies that can improve gear performance.

2. Literature Review

Numerous studies have explored gear modeling and simulation, focusing on dynamic behavior and fatigue life. Du et al. investigated the vibration characteristics of high-speed helical gear in pure electric vehicles by establishing a six-degree-of-freedom bending-torsion-axial dynamics model. Zhou et al. developed a six-degree-of-freedom nonlinear dynamics model for a cylindrical gear system, considering tooth surface friction, backlash, and time-varying meshing stiffness, and analyzed the effects of temperature variations and excitation frequencies on system dynamics. Wang established a multi-degree-of-freedom rotor-bearing system model using the Rayleigh beam model and Lagrange equations to derive the system’s critical speed and unbalanced response.

Additional studies by Liu , Liu and Qu , Yue et al. , and Yan et al. have further contributed to the understanding of gear dynamics and fatigue behavior. However, many of these studies have focused on low-speed gears or constructed incomplete dynamics equations. This paper aims to fill this gap by establishing a more comprehensive dynamics equation for high-speed helical gear and analyzing the effects of gear modification on dynamic meshing and fatigue life.

3. Methodology

3.1 System Modeling

The rotor-bearing-gear system is modeled using a finite element approach, considering multiple degrees of freedom at each node. The system comprises shaft elements, disk elements, eccentric mass elements, and bearing elements.

3.1.1 Shaft Element Modeling

The shaft elements are modeled using Timoshenko beam elements, which account for both bending and torsion. Each node in the beam element has six degrees of freedom (x, y, z, θx, θy, θz).

The mass, gyroscopic, and stiffness matrices of the beam elements are derived using the following equations:

M=MT+MR+Mθ

MT=∫0LρA[Nx00Ny][NxTNyT]ds

MR=∫0LρJp[Nθx00Nθy][NθxTNθyT]ds

Mθ=∫0LρANθzNzTds+∫0LJdNθzNθzTds

G=2ρJpL0a0000−a00000000b0000−b00000000c0000−c0

K=∫0LEANx′Ny′Nθz[Nx′TNy′TNθzT]ds+∫0LGJp[Nθy′−Nθx′][Nθy′T−Nθx′T]ds

3.1.2 Disk Element Modeling

Disk elements are modeled as rigid bodies, and the meshing part is simulated using spring elements. The mass and gyroscopic matrices for the disk elements are given by:

M=m1000000m1000000m1000000Id1000000Id1000000Ip1⊕m2000000m2000000m2000000Id2000000Id2000000Ip2

G=[0symmetric matrixskew-symmetric matrix0]

3.1.3 System Dynamics Equation

The dynamics equation of the rotor-bearing-gear system is given by:

Mx¨+(C+ΩG)x˙+Kx=F

where M is the mass matrix, C is the damping matrix, G is the gyroscopic matrix, K is the stiffness matrix, Ω is the rotational speed, F is the external force vector, and x, x˙, and x¨ are the displacement, velocity, and acceleration vectors, respectively.

3.2 Gear Modification

To improve the dynamic behavior and fatigue life of the helical gear, modifications are applied to both the tooth profile and lead directions. The modifications are performed using KISSsoft, with key parameters summarized in Table 1.

Table 1: Modification Parameters

| Parameter | Small Gear | Large Gear |

|---|---|---|

| Tooth Root Relief (μm) | – | 10 |

| Lead Crown (μm) | 5 | – |

| Helix Angle Correction (μm) | -3 | – |

3.3 Simulation Setup

The modified and unmodified gear models are imported into ANSYS Workbench for transient analysis. Material properties for 20CrMnTiH are specified, and contact settings are defined. Meshing is performed using hexahedral elements for higher accuracy, and the contact surfaces are refined to capture stress and deformation details.

4. Results and Discussion

4.1 Natural Frequencies and Campbell Diagram

The natural frequencies of the rotor-bearing system are calculated using the established dynamics equation. The first six natural frequencies are presented in Table 2, and the Campbell diagram.

Table 2: Natural Frequencies

| Mode Order | Natural Frequency (Hz) | Vibration Mode |

|---|---|---|

| 1 | 22 | 1st Order Reverse Whirl |

| 2 | 26 | 1st Order Forward Whirl |

| 3 | 59 | 2nd Order Reverse Whirl |

| 4 | 103 | 2nd Order Forward Whirl |

| 5 | 323 | 3rd Order Reverse Whirl |

| 6 | 398 | 3rd Order Forward Whirl |

4.2 Displacement Response

The displacement responses of the small and large gears are calculated using the Newmark-β method. The time-domain and frequency-domain plots, respectively.

Similar plots for the large gear are also generated and analyzed.

4.3 Stress Analysis

The equivalent stress distributions of the unmodified and modified gears are presented.

The maximum equivalent stress in the unmodified gear is 1579 MPa, which decreases to 1426 MPa after modification, representing a 6.6% reduction.

4.4 Fatigue Life Analysis

The fatigue life and safety factor distributions are analyzed using the S-N curve of 20CrMnTiH material. The fatigue life distributions of the unmodified and modified helical gear.

The minimum fatigue life in the unmodified gear is improved significantly after modification, as evidenced by the increased fatigue life in the modified gear.

Similarly, the safety factor distributions before and after modification are compared .

The minimum safety factor increases from 0.83 to 0.92 after modification, indicating improved reliability.

5. Conclusion

This paper presents a comprehensive analysis of the dynamic meshing and fatigue life of high-speed helical gear. By establishing a multi-degree-of-freedom rotor-bearing system dynamics equation and applying gear modifications, the dynamic behavior and fatigue life of the gears are significantly improved. The key findings are summarized below:

- The natural frequencies and vibration modes of the rotor-bearing system are successfully calculated using the finite element method.

- The displacement responses of the gears are accurately simulated using the Newmark-β method.

- Gear modifications effectively reduce the equivalent stress, increase fatigue life, and improve safety factors.

- The analysis provides valuable insights into the design and optimization of high-speed helical gear for various industrial applications.