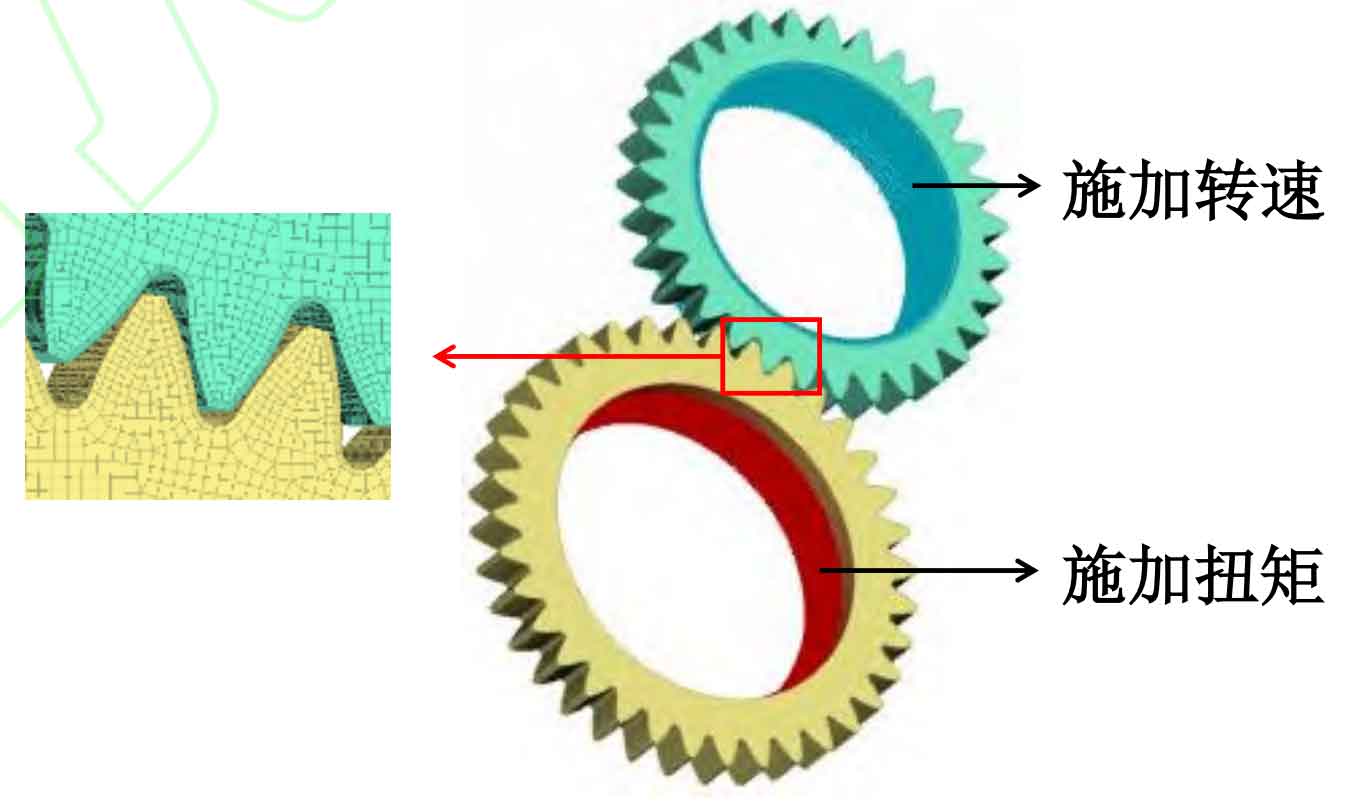

Based on the model in Figure 1, the center distance deviation is set to 0.06 mm, the rotational speed n is set to 5000 r/min, and the basic load torque T is set to 200 N · m. The finite element models of spur gear pairs with torques of 0.5T, T, 1.5T, and 2T are established respectively. Import the model into LS-DYNA for simulation solution.

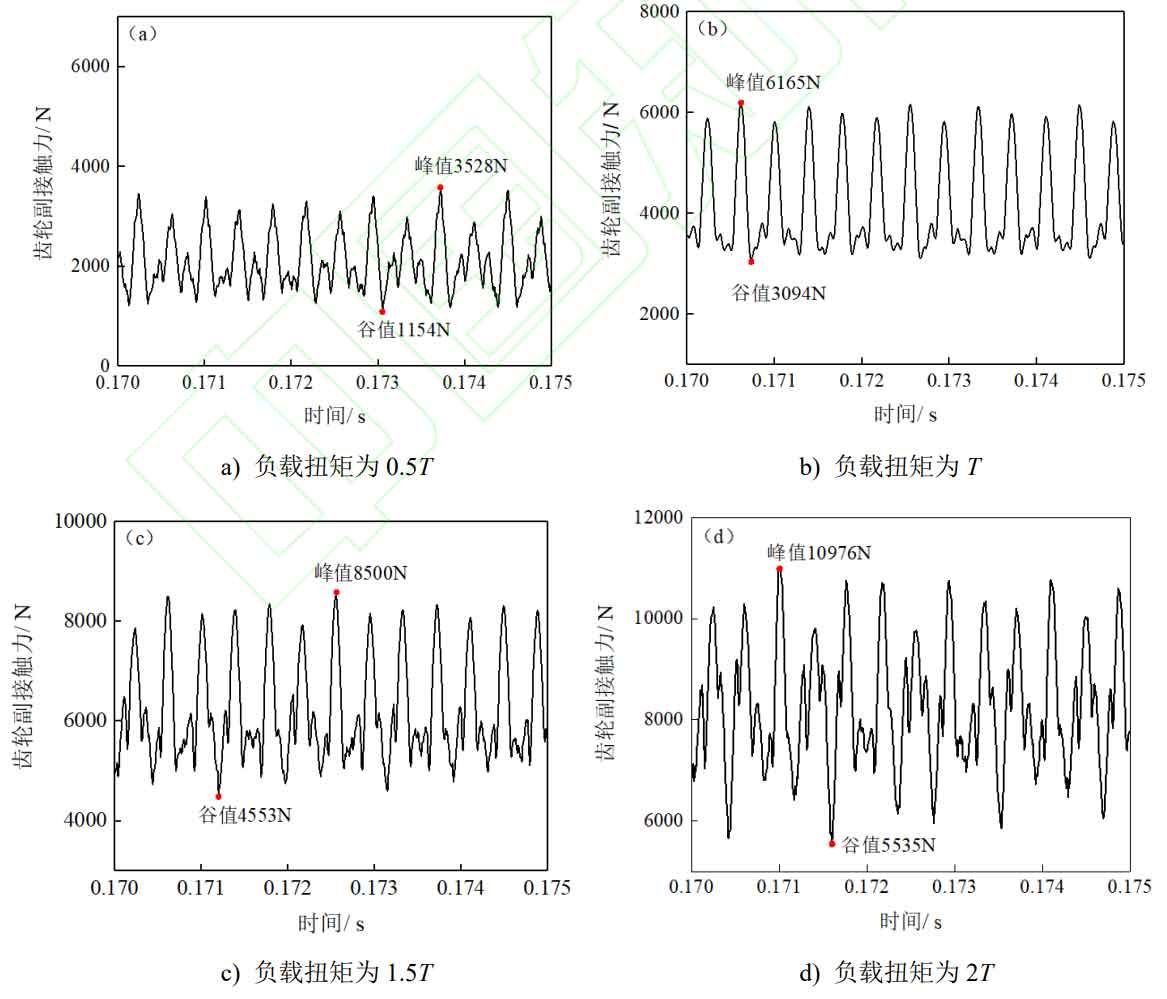

Extract the meshing force curves of the spur gear pair during the meshing stability stage of 0.17s-0.175s under different torques, as shown in Figure 2.

According to the meshing force curve, the fluctuation of the meshing force of spur gear pairs will exhibit a non-linear increasing trend with the increase of torque. The fluctuation of the meshing force when the torque is 0.5T, T, 1.5T, and 2T is 2374N, 3071N, 3947N, and 5441N, respectively. In addition, when the torque is 0.5T, T, and 1.5T, the periodicity of the meshing force is good, but when the torque is 2T, the periodicity of the meshing force significantly decreases, indicating that excessive load torque can affect the meshing stability of spur gear pairs.