In the research field of straight bevel gear dynamics, the indexes commonly used to evaluate the dynamic performance of straight bevel gear transmission system include dynamic load, dynamic load coefficient, average stiffness and vibration acceleration:

1) Dynamic load

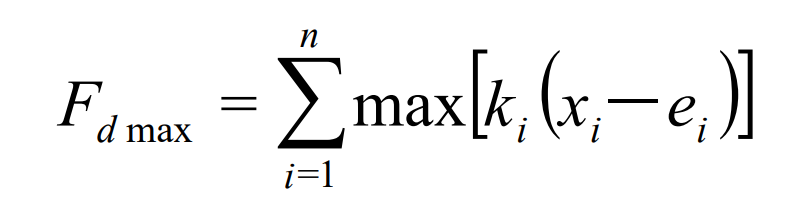

Different degrees of vibration will occur during meshing transmission of straight bevel gears. This vibration causes contact load between teeth. The maximum value of contact load is dynamic load, which can be obtained by the following formula:

Where, Ki, Xi and EI are the single tooth stiffness, relative vibration displacement and straight bevel gear error at meshing position I respectively, and N is the number of equal points in a meshing cycle.

2) Dynamic load coefficient

The dynamic load coefficient kV is the ratio of the normal static load of the gear tooth to the maximum dynamic load on the gear tooth in a straight bevel gear meshing cycle. Its expression is as follows:

3) Average stiffness

The average stiffness of straight bevel gear pair refers to the average value of tooth stiffness at each position along the meshing line in a meshing cycle, and its calculation formula is as follows:

4) Root mean square value of change amplitude of meshing stiffness

By analyzing the change of the root mean square value of the change amplitude of meshing stiffness in a meshing cycle, the impact condition of tooth meshing can be obtained. The expression of the root mean square value of the change amplitude of meshing stiffness is as follows:

5) Vibration acceleration

The root mean square value of the vibration acceleration of the straight bevel gear system changes with the change of the vibration load. The vibration condition of the straight bevel gear system can be seen from the change of the root mean square value of the vibration acceleration of the straight bevel gear.

The dynamic contact load (dynamic load) and vibration response curve of straight bevel gear transmission can be obtained by using RomaxDesigner for dynamic analysis.