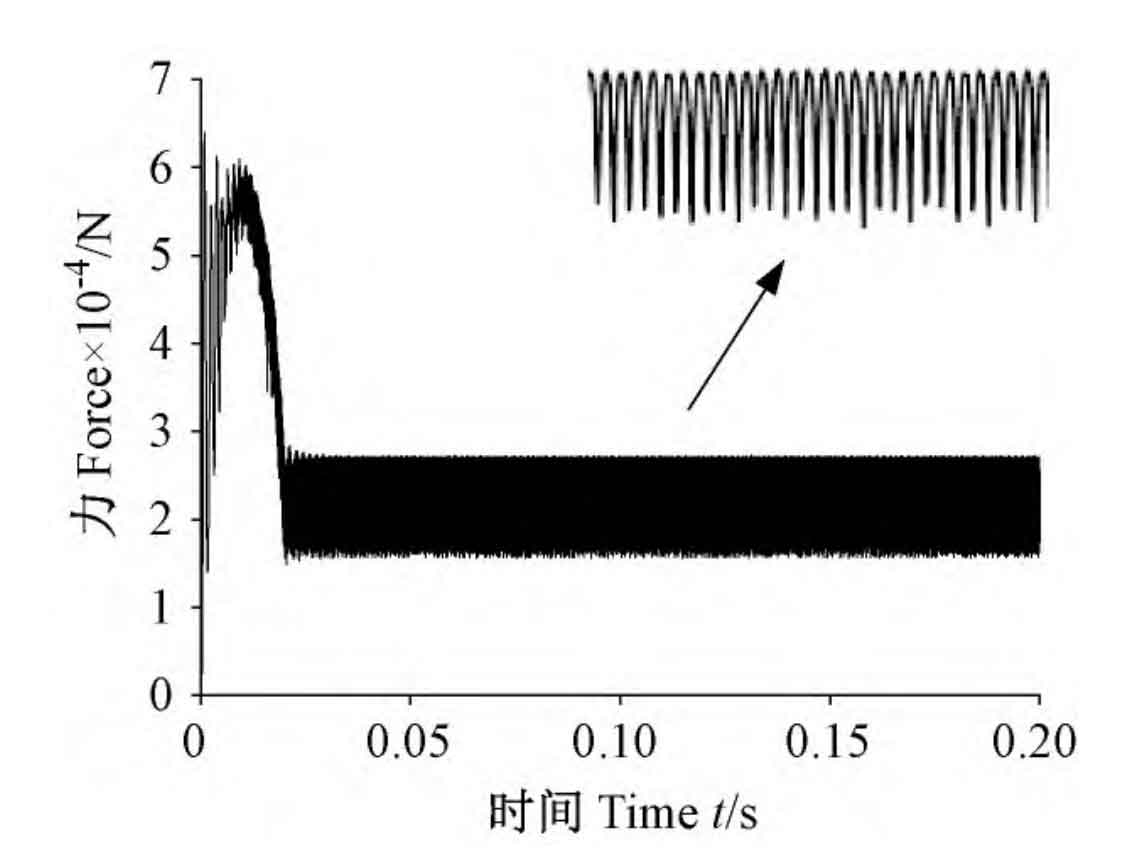

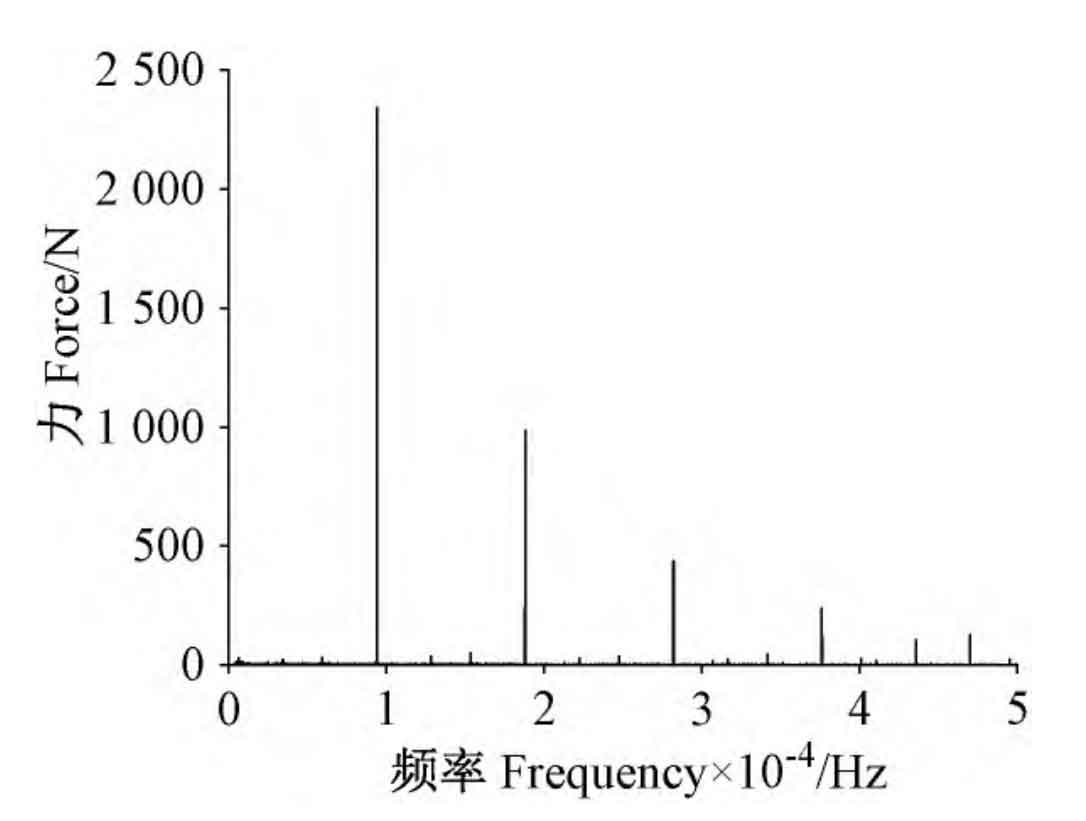

Further harmonic response analysis is carried out on the basis of modal analysis. Firstly, the multi-body dynamics software Adams is used to extract the dynamic meshing force of spiral bevel gear pair, and its time-domain spectrum and spectrum are shown in Fig. 1 and Fig. 2.

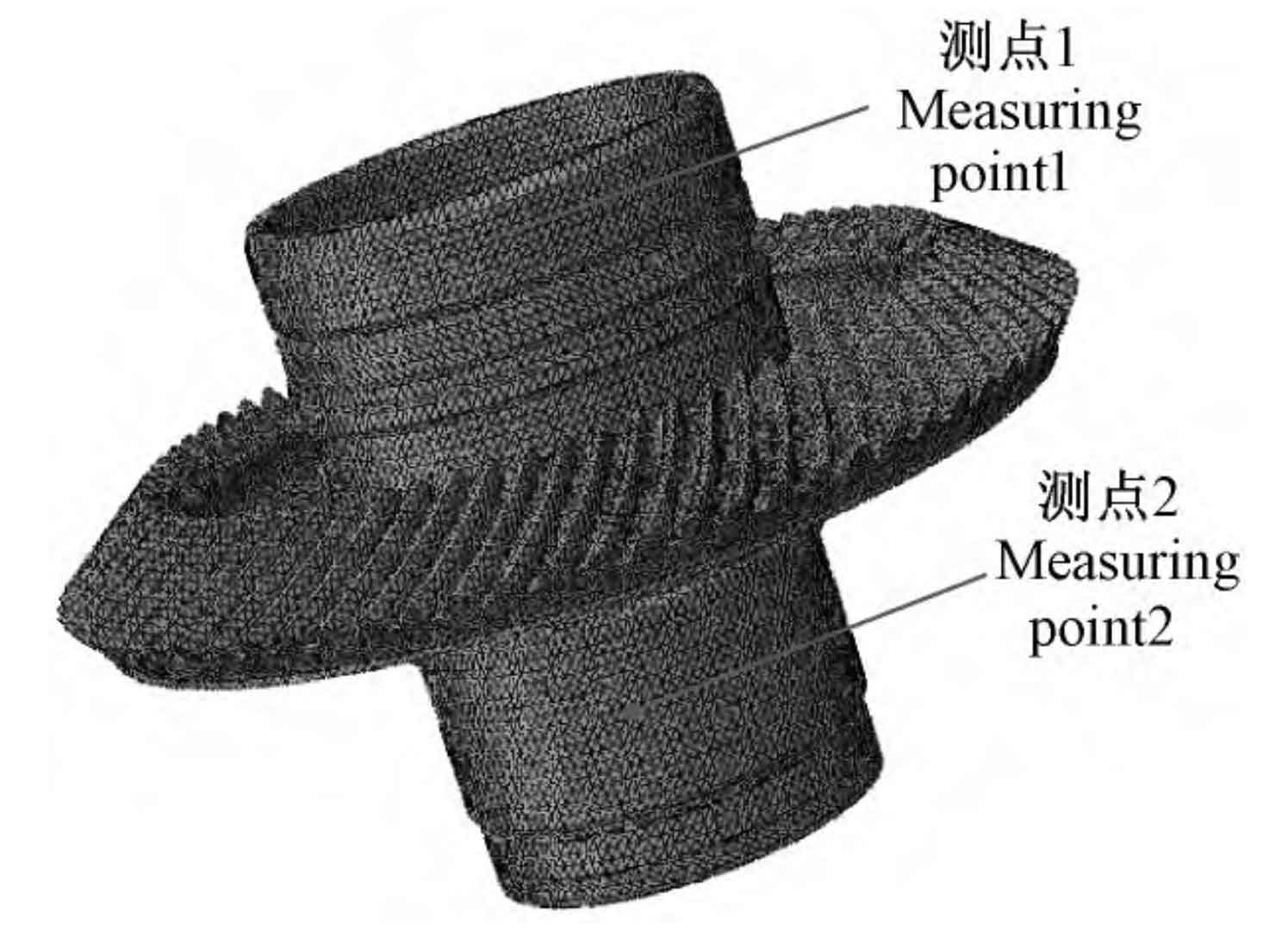

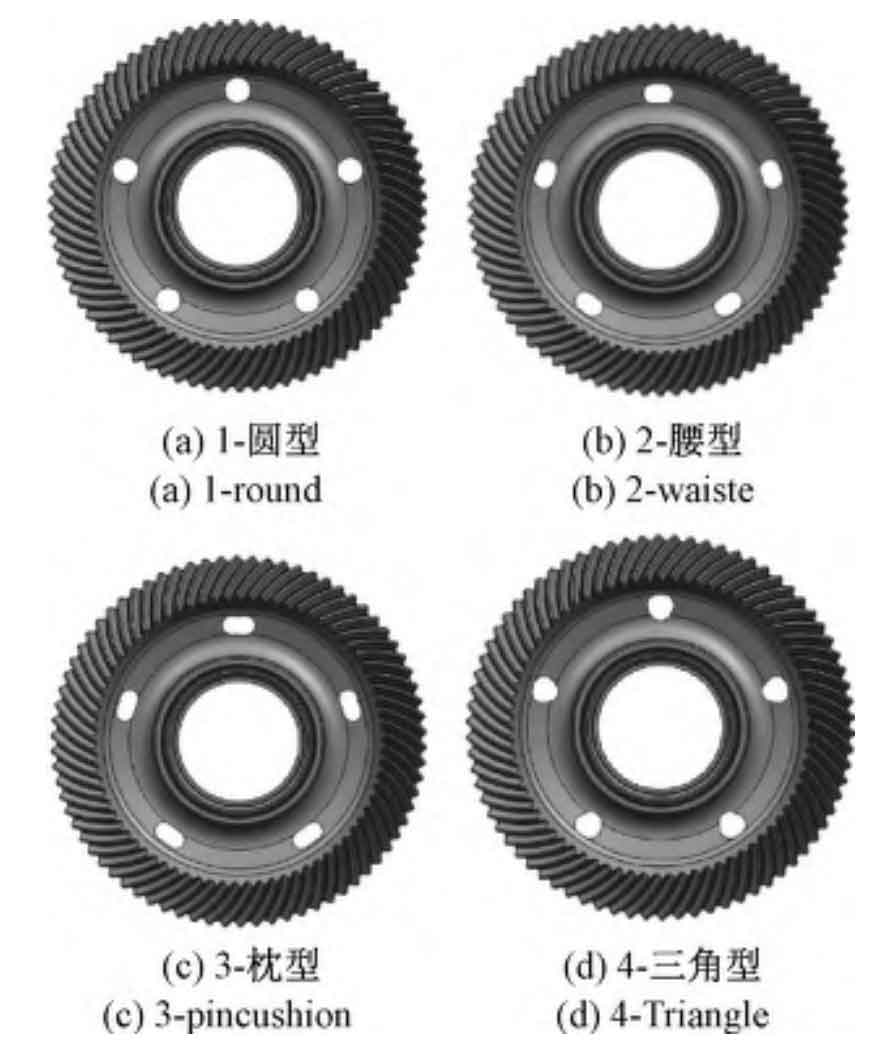

It can be seen from Figure 1 that the amplitude of the impact force at the moment of starting is much greater than that of the steady-state process, which is due to the existence of the impact force at the moment of starting. Figure 2 shows that the meshing force peaks at the meshing frequency of 9 405 Hz and its frequency multiplier. Introduce the meshing force component extracted from Adams into Abaqus and apply it to the meshing contact line of the driven spiral bevel gear. Four structures with equal quantity, equal area and different hole patterns are given, as shown in Figure 3. Two measuring points are selected at the connection position between the shaft and the bearing. The measuring point position is shown in Figure 4. The table shows the vibration comparison results of two measuring points under four passes.

| Pass | Measuring point 1 | Measuring point 2 |

| 1 | 1.736X10^6 | 1.715X10^6 |

| 2 | 1.541X10^6 | 1.511X10^6 |

| 3 | 1.558X10^6 | 1.513X10^6 |

| 4 | 1.770X10^6 | 1.746X10^6 |

It can be seen from the table that the RMS value of vibration acceleration at measuring point 1: 2-waist hole < 3-pillow hole < 1-round hole < 4-triangular hole; the RMS value of vibration acceleration at measuring point 2: 2-waist hole < 3-pillow hole < 1-round hole < 4-triangular hole. It can be seen that the vibration magnitude of different passes at two measuring points is consistent, and the waist hole phase has the most obvious inhibition effect on the vibration transmission of the other three passes, which can be used as the preferred pass.