When the load torque is 80 N · m, the input speed is 600 r/min, 1400 r/min and 2200 r/min, which are set as condition 1, condition 2 and condition 3 respectively; When the input speed is 1400 r/min, the load torque is 40 N · m, 80 N · m, and 120 N · m, which are respectively set as Condition 4, Condition 2, and Condition 5. The simulation time is 1s and the simulation step is 2.5 × 10-3 s。

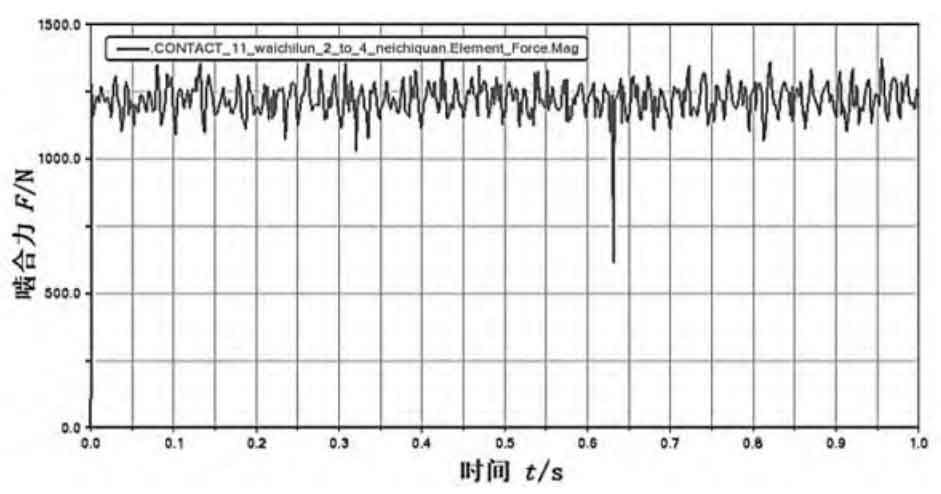

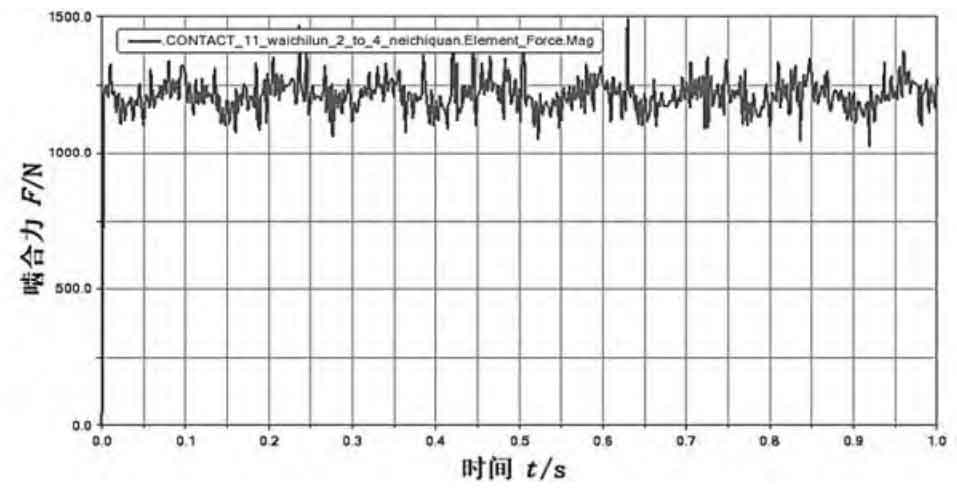

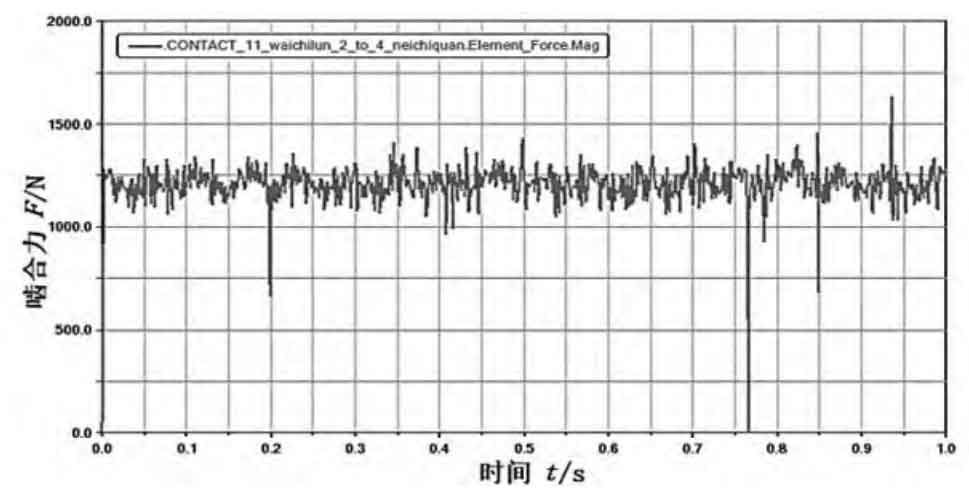

(1) Influence of different input speeds on dynamic meshing force simulation of planetary gear reducer

As shown in Figure 1, under the same working condition, the dynamic simulation value of meshing force fluctuates around 1214.07 N, the theoretical calculation value is 1303.69 N, and the error is 6.87%, within a reasonable range. During dynamic operation, the eccentric force and unbalanced inertial force generated by the reducer cause the meshing force to fluctuate up and down. The time-varying meshing stiffness and tooth deformation of the planetary gear will also affect the meshing force fluctuation. When the load torque is constant, the speed and meshing force fluctuations are positively correlated.

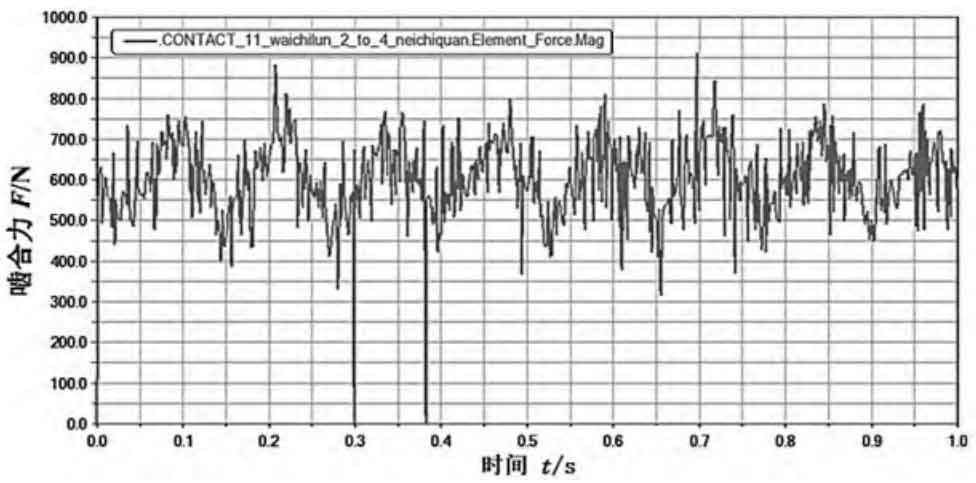

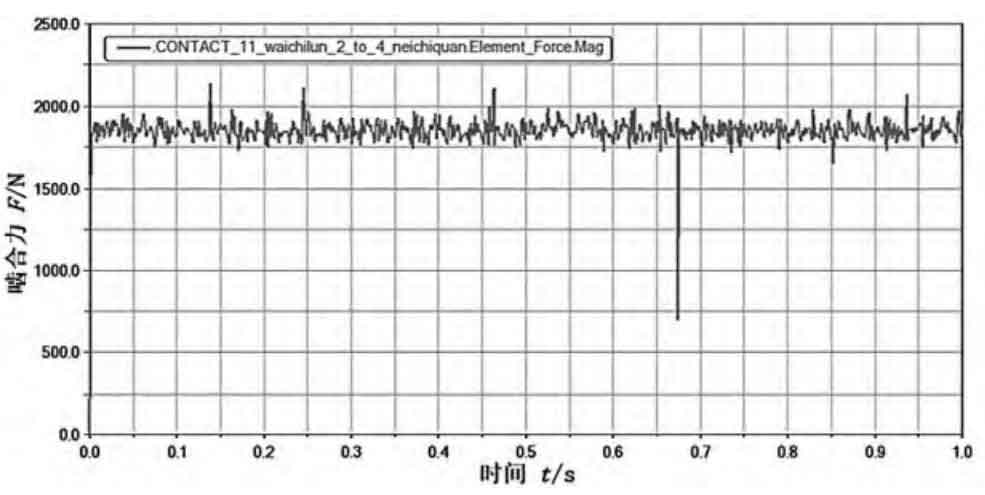

(2) Influence of Different Load Torques on Dynamic Engagement Force Simulation of Planetary Gear Reducer

Combined with Figure 2 and Figure 1 (b), with the increase of load torque, the RMS values of the dynamic simulation results of meshing force are 606.18 N, 1214.07 N, 1849.17 N, and the theoretical calculated values are 651.85 N, 1303.69 N, and 1951.64 N. The errors between the simulation values of meshing force and the theoretical calculated values are 7.01%, 6.87%, and 5.41%, respectively, which are within a reasonable range.

The existence of eccentric force, unbalanced inertial force, time-varying meshing stiffness and gear tooth deformation will lead to fluctuation. When the speed is maintained at 1400 r/min, the meshing force value increases with the increase of load torque, but the fluctuation amplitude decreases. Because the meshing force of the planetary gear is dynamic fluctuation, it will have a certain impact on the fatigue life of the planetary gear.

| Typical working conditions | Max/N | RMS/N |

| 600 r/min, 80 N·m | 1,453.54 | 1,219.86 |

| 1,400 r/min, 80 N·m | 1,492.75 | 1,214.07 |

| 2,200 r/min, 80 N·m | 1,628.77 | 1,208.66 |

| 1,400 r/min, 40 N·m | 912.66 | 606.18 |

| 1,400 r/min, 120 N·m | 2,139.88 | 1,849.17 |