Abstract

Tooth surface pitting is a major failure mode of helical gears, impacting their reliability and durability. Accurate diagnosis of pitting severity and quantity requires extensive experimental data, which is often difficult to obtain. This paper proposes a combined simulation and experimental approach to identify the extent and number of pitting corrosions on helical gear tooth surfaces. Dynamic models for different types of pitting faults, including single-tooth surface pitting and multi-tooth surface pitting, are established. Envelope spectrum analysis is performed on the dynamic response signals to obtain characteristic response laws in both time and frequency domains. Vibration signals from gear contact fatigue experiments are analyzed to validate the accuracy of the dynamic models. The results demonstrate that the proposed dynamic models can effectively diagnose and identify various pitting severities and multi-tooth surface pitting, providing a valuable basis for fault diagnosis and health prediction in gear transmission systems.

1. Introduction

Helical gears are essential components in automotive transmissions, engineering machinery, aerospace systems, rail transportation, and military vehicles. Operating in complex environments at high speeds, helical gears primarily experience contact stress on their tooth surfaces and bending stress on their roots. Fatigue pitting on the tooth surfaces significantly reduces the strength of gears, leading to premature failure and affecting the overall performance and lifespan of the transmission system. Early detection of pitting faults in helical gears is crucial for ensuring the reliable operation of automotive automatic transmissions and related power transmission devices.

1.1 Background and Motivation

In recent years, researchers have conducted in-depth studies on gear pitting from various perspectives. However, most studies have focused on spur gears, with limited attention given to helical gears. Moreover, most studies on helical gears have primarily concentrated on single-tooth surface pitting, neglecting multi-tooth surface pitting faults. Therefore, there is a pressing need for comprehensive research on the dynamic characteristics and fault diagnosis of helical gears with various types of pitting faults.

1.2 Objectives

The primary objectives of this study are:

- Establish dynamic models for helical gears with single-tooth surface pitting and multi-tooth surface pitting faults.

- Analyze dynamic response signals in the time and frequency domains using envelope spectrum analysis.

- Validate the accuracy of the proposed dynamic models through experimental data from gear contact fatigue tests.

- Provide a diagnostic basis for identifying pitting faults in helical gears, supporting the development of fault diagnosis and health prediction methods for gear transmission systems.

2. Literature Review

Extensive research has been conducted on gear pitting faults, primarily focusing on spur gears. Key studies relevant to this work are reviewed below.

2.1 Spur Gear Pitting Studies

LI Y et al. compared the system dynamics of healthy spur gears and those with pitting faults, analyzing the excitation sources of vibration frequency components. LIANG X et al. modeled gears with varying degrees of pitting and studied their influence on mesh stiffness. HUANGFU Y et al. developed a dynamic model for spalled gear pairs based on loading contact analysis and investigated the fault characteristics of different pitting severities.

2.2 Helical Gear Studies

Studies specifically focusing on helical gears and their pitting faults are limited. HAN L et al. studied the effect of tooth spalling and local breakage on the time-varying mesh stiffness of helical gears. MA R et al. investigated the dynamics and fault mechanisms of helical gear pairs with spalling defects. RINCON A et al. examined the influence of cracks and pitting defects on the meshing of helical gears.

3. Methodology

The proposed methodology combines simulation and experimentation to comprehensively study the dynamic characteristics and fault diagnosis of helical gears with pitting faults.

3.1 Modeling Approach

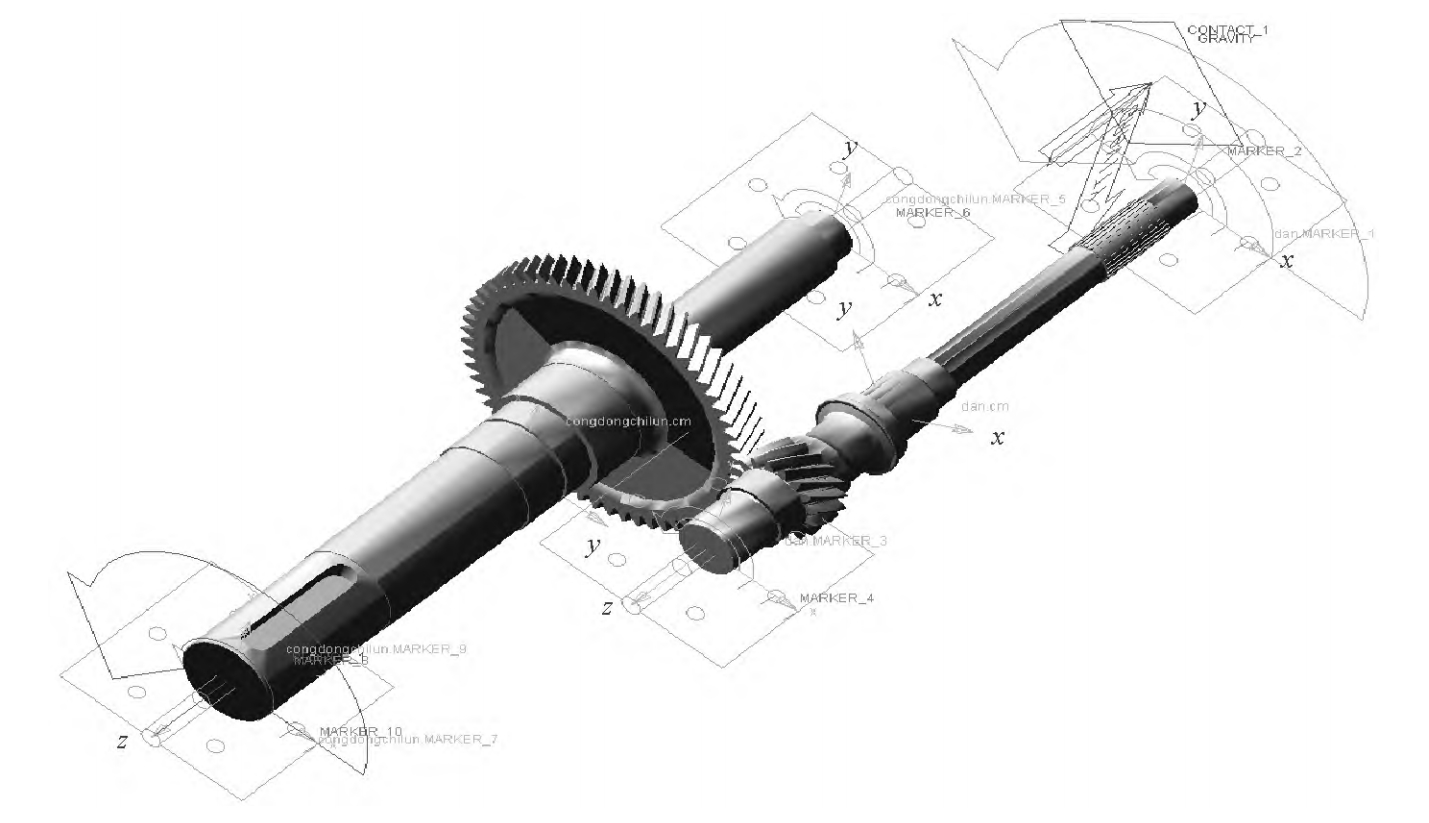

Three-dimensional (3D) models of helical gears with varying pitting severities and numbers of affected tooth surfaces are created using CAD software. These models are then imported into a dynamics simulation environment for analysis.

3.2 Simulation Setup

The dynamic simulation setup includes:

- Geometry and Meshing: Import 3D models of pitted helical gears into the simulation software.

- Constraints and Loads: Apply rotational constraints at the shaft ends and specify the driving speed and load torque.

- Contact Definition: Define contact parameters based on material properties and mesh stiffness calculations.

- Analysis: Run the simulation to obtain dynamic response signals.

3.3 Experimental Validation

An experimental setup is developed to validate the simulation results. Key components include:

- Test Rig: A dedicated test rig with motors, gears, bearings, and sensors is constructed.

- Data Acquisition: Vibration accelerometers are used to capture vibration signals during gear operation.

- Signal Processing: Envelope spectrum analysis is performed on the acquired signals to extract fault features.

4. Simulation Modeling

4.1 Gear Geometry and Pitting Defects

Helical gear parameters for a 7-speed dual-clutch automatic transmission are used as the basis for modeling (Table 1). Pitting defects are modeled as elliptical pits of varying sizes and depths on the tooth surfaces.

Table 1: Gear parameters for the modeled helical gears

| Parameter | Value |

|---|---|

| Number of Teeth | 17 (Driving), 60 (Driven) |

| Normal Modulus | 2.1175 mm |

| Pressure Angle | 19.8° |

| Helix Angle | 16.9° |

| Tooth Width | 20 mm |

4.2 Modeling Pitting Faults

Pitting faults are modeled as follows:

- Single-tooth Surface Pitting: Mild (5×1.5 mm ellipse) and severe (10×1.5 mm ellipse) pitting on a single tooth surface.

- Multi-tooth Surface Pitting: Pitting on two or more tooth surfaces, with varying sizes and depths.

Modeled helical gears with (a) no pitting, (b) mild single-tooth surface pitting, (c) severe single-tooth surface pitting, (d) double-tooth surface pitting, and (e) multi-tooth surface pitting.

4.3 Simulation Setup and Analysis

Dynamics simulations are set up with realistic constraints, loads, and contact definitions. Key parameters include:

- Constraints: Rotational constraints applied at the shaft ends.

- Loads: Driving speed of 2500 rpm and load torque of 840 N·m.

- Contact Definition: Based on mesh stiffness calculations and material properties.

5. Results and Discussion

5.1 Simulation Results

The dynamic response signals from the simulations are analyzed in both the time and frequency domains.

5.1.1 Time Domain Analysis

In the time domain, the contact forces exhibit distinct patterns for different pitting severities and numbers of affected tooth surfaces.

Time domain contact forces for (a) normal gear, (b) mild single-tooth surface pitting, (c) severe single-tooth surface pitting, (d) double-tooth surface pitting, and (e) multi-tooth surface pitting.

5.1.2 Frequency Domain Analysis

Envelope spectrum analysis reveals characteristic frequency components and their variations with pitting severity and number of affected tooth surfaces.

Frequency domain envelope spectra for (a) normal gear, (b) mild single-tooth surface pitting, (c) severe single-tooth surface pitting, (d) double-tooth surface pitting, and (e) multi-tooth surface pitting.

5.2 Experimental Validation

Experimental results from the gear contact fatigue test rig validate the simulation findings.

5.2.1 Time Domain Validation

Vibration acceleration signals captured from the test rig show similar patterns to the simulated contact forces.

Time domain vibration acceleration signals for (a) normal gear, (b) mild single-tooth surface pitting, (c) severe single-tooth surface pitting, (d) double-tooth surface pitting, and (e) multi-tooth surface pitting.

5.2.2 Frequency Domain Validation

Envelope spectrum analysis of the experimental signals matches the simulated frequency domain results.

Experimental frequency domain envelope spectra for (a) normal gear, (b) mild single-tooth surface pitting, (c) severe single-tooth surface pitting, (d) double-tooth surface pitting, and (e) multi-tooth surface pitting.

6. Conclusion

This study comprehensively investigated the dynamic characteristics and fault diagnosis of helical gears with various pitting faults through simulation and experimentation. Key findings include:

- Dynamic Models: Accurate dynamic models were established for helical gears with single-tooth surface pitting and multi-tooth surface pitting faults.

- Time and Frequency Domain Analysis: Distinct patterns were observed in both the time and frequency domains, enabling the identification of pitting severities and numbers of affected tooth surfaces.

- Experimental Validation: Experimental results validated the accuracy of the simulation models, confirming their usefulness for fault diagnosis.

- Diagnostic Basis: The proposed methodology provides a solid foundation for developing diagnostic tools for helical gear pitting faults, supporting the maintenance and reliability of gear transmission systems.