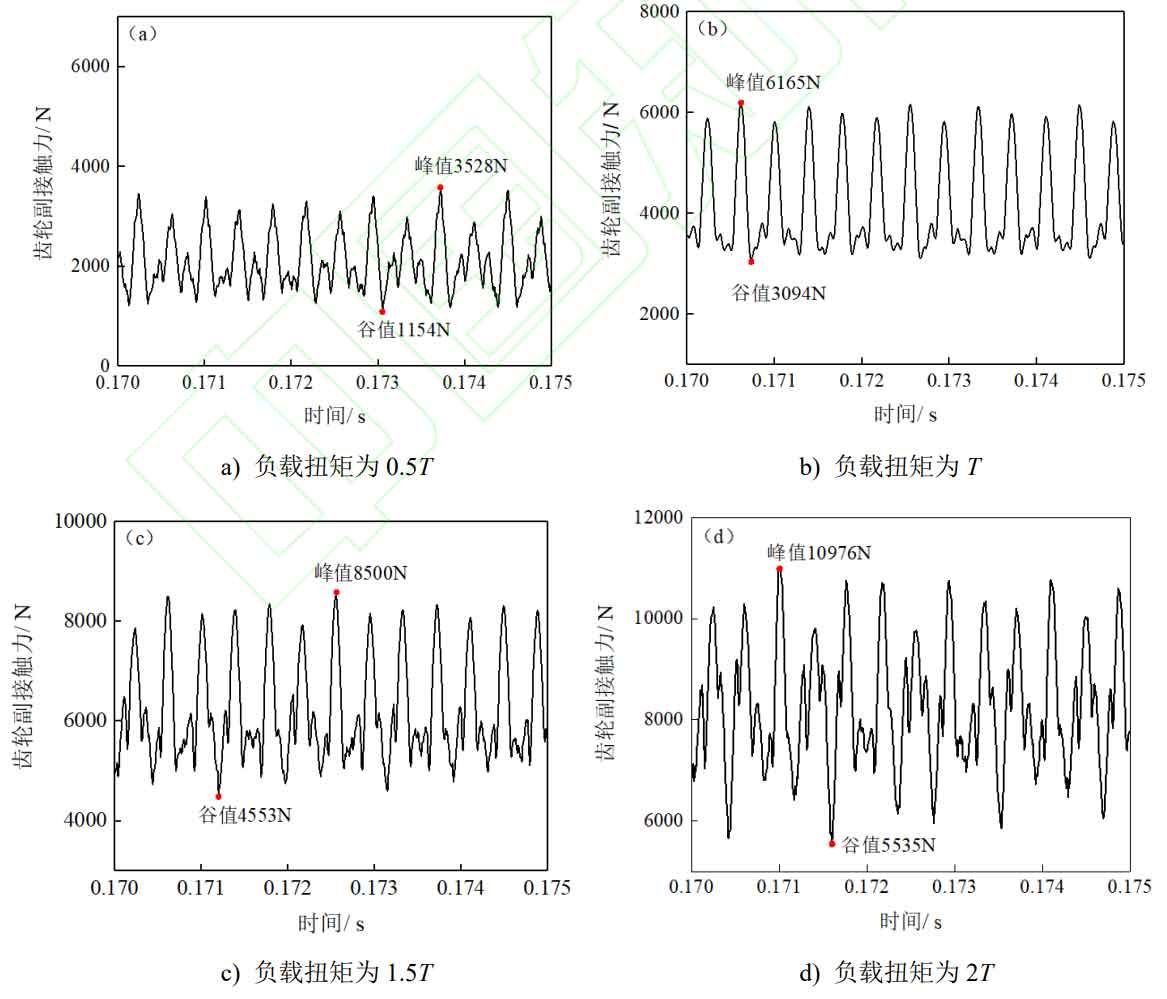

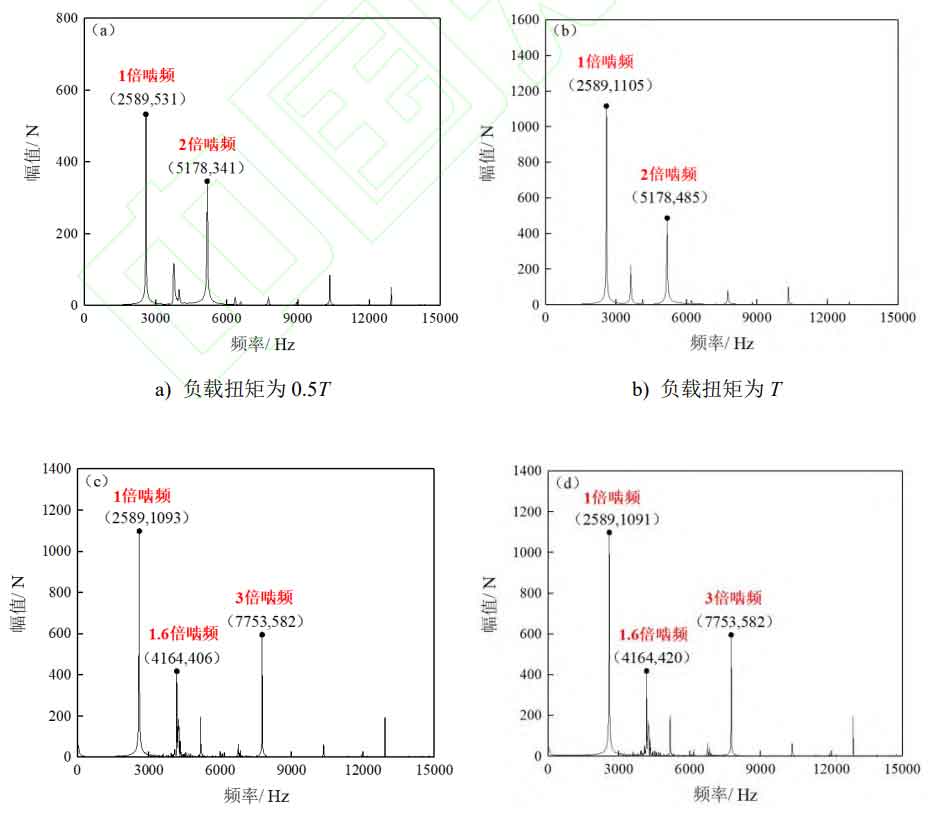

Perform Fourier transform on the meshing force curve of the spur gear pair in Figure 1 to obtain a spectrum diagram of the meshing force of the spur gear pair, as shown in Figure 2.

According to the spectrum diagram of spur gear meshing force, as the torque increases, the spectrum amplitude of the same frequency gradually increases, and finally reaches a relatively stable level. In addition, when the torque is 0.5T and T, the amplitudes of the main 1-fold and 2-fold meshing spectral lines in the spectrum of spur gear pairs are higher, while the amplitudes of other sidebands are lower; When the torque is 1.5T and 2T, the 1 time meshing spectral line is still the main component, but the amplitude of the 2 times meshing spectral line in the spectrum of the spur gear pair significantly decreases, while the amplitude of the 1.6 times and 3 times meshing spectral line significantly increases. According to the analysis results of the spoke vibration, the reason for the above phenomenon is that as the torque increases, the friction between the teeth increases. When the meshing point passes through the node, the magnitude and direction of the friction force on the teeth suddenly changes, causing spur gear pitch line impact, resulting in three impacts, namely, meshing in, meshing out, and pitch line impact, experienced by the teeth within a meshing cycle, These impacts are transmitted along the teeth to the spoke, which in turn causes axial vibration of the spoke.

Increasing the load torque will exacerbate the meshing vibration of the spur gear pair. When the torque reaches a certain value, in addition to meshing in and out impacts, there will also be pitch line impacts and abnormal vibration of the spokes during the meshing process of the spur gear pair, resulting in poor meshing performance of the spur gear pair.