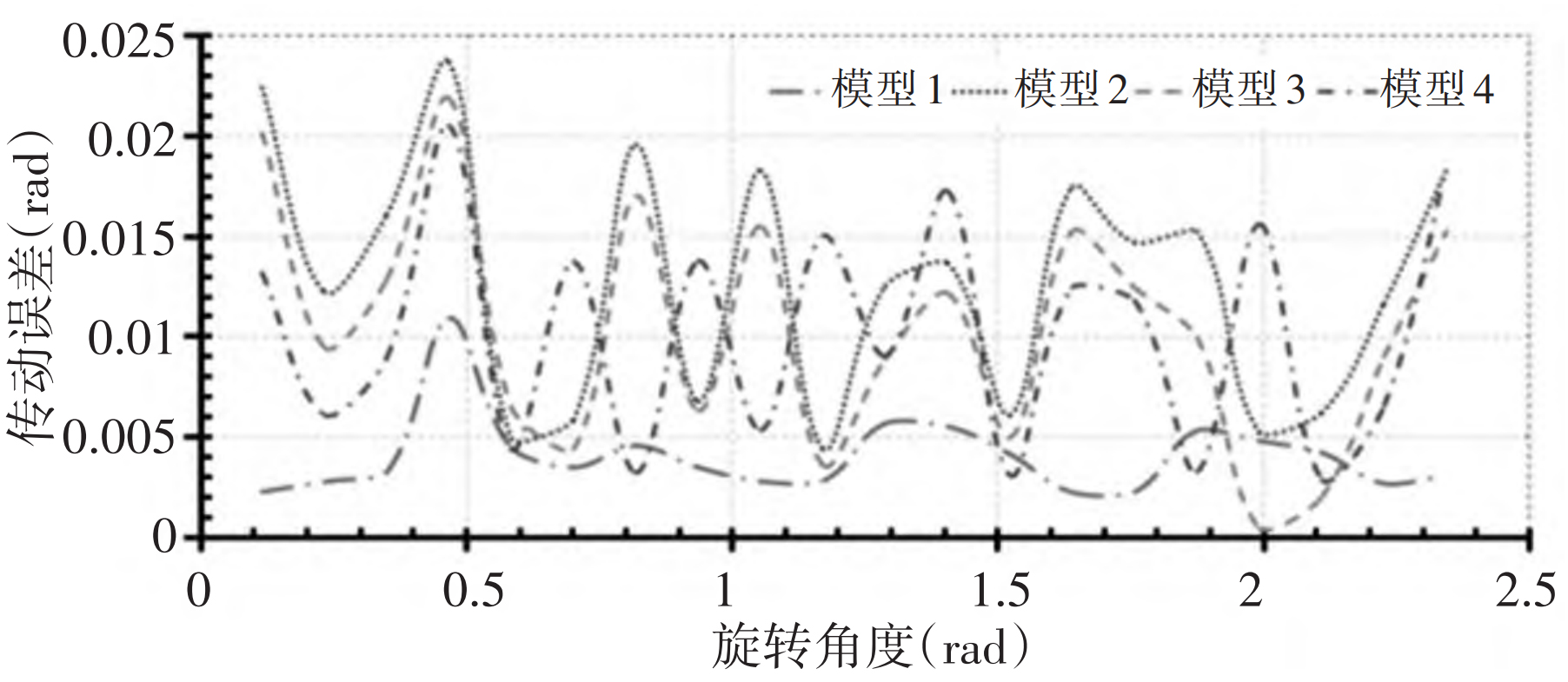

In the static meshing analysis, the influence of the load of spiral bevel gears on the meshing results has been obtained. Therefore, in the dynamic analysis process, only the analysis under the load of 500N · m is considered, and the transmission error curve results obtained are as shown in the figure.

Model 1: axial offset of large gear, Model 2: axial offset of small gear, Model 3: shaft intersection angle, Model 4: shaft spacing.

Similarly, the statistical analysis method is used to draw the error analysis table, as shown in the table.

From the table, we can see that the amplitude, mean value and mean square deviation are from small to large in order: axial deviation of big gear, axial spacing deviation, axial intersection angle deviation, and axial deviation of small gear. The dynamic analysis results are basically consistent with the static ones.

| Model | Amplitude | Average value | Standard deviation |

| Axial deviation of large gear | 0.010892832 | 0.004016559 | 0.001910399 |

| Axial offset of pinion | 0.023608162 | 0.012730864 | 0.006008592 |

| Axis intersection offset | 0.021818879 | 0.010369482 | 0.005805038 |

| Axis spacing offset | 0.018459501 | 0.010206753 | 0.005501538 |

From the dynamic error transfer diagram, we can also see that the amplitude fluctuation at the initial stage is large, and then the vibration gradually decreases and tends to be stable. The main reason for this phenomenon is that in the process of dynamic transmission, the meshing in and out impact in the initial state is relatively serious, and then the spiral bevel gear speed reaches a stable level, which will weaken and gradually stabilize.

(1) The periodicity of transmission error is caused by the impact received when the spiral bevel gear meshes in and out. The periodicity of the transmission error curve is more regular when the load is lower.

(2) In static analysis, the error value increases with the increase of load, which directly affects the transmission accuracy. However, with the increase of load, the amplitude fluctuation of transmission error is relatively gentle, which effectively reduces the noise generated by vibration.

(3) The amplitude of the dynamic analysis at the initial stage is larger than that of the static analysis, and the subsequent results are basically consistent with the static analysis.

(4) It can be obtained that the transmission error values of four kinds of error offsets affect the meshing performance from small to large: the axial displacement of the big gear, the shaft spacing, the shaft intersection angle, and the axial displacement of the small gear. Therefore, when we cannot control the installation error, we should try to reduce the installation error types of spiral bevel gears that have a great impact on the meshing performance.