1. Introduction

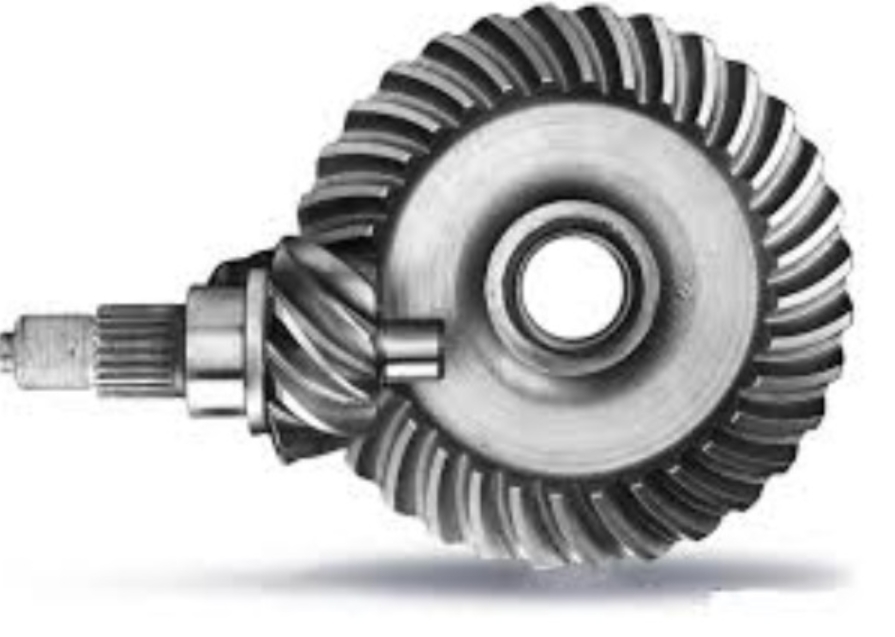

Hypoid gear is widely recognized for their ability to transmit motion between non-parallel, non-intersecting axes with high efficiency and compact design. However, high reduction hypoid gear face unique challenges due to their extreme speed ratios (often exceeding 60:1), including insufficient curvature of the wheel tooth profile and excessive twist of the pinion tooth surface. This study addresses these issues through tool modification strategies, computational modeling, and dynamic performance validation. By integrating ease-off topology analysis and motion simulation, we demonstrate how controlled modifications enhance meshing performance while maintaining manufacturing simplicity.

2. Mathematical Modeling of Hypoid Gear Tooth Surfaces

2.1 Tool Modification for the Wheel

To compensate for the curvature deficiency in high reduction hypoid gear wheels, a parabolic tool modification is applied along the w-axis. The modified cutter profile is defined in the coordinate system Sc(xc,yc,zc):

Parabolic Tool Profile Equations:w=0.5a1(u−u0)2,w′=a1(u−u0)

where a1 is the curvature parameter and u0 is the reference point. The pressure angle α(u) becomes a function of u:α(u)=α0+arctan(w′)

The modified cutter surface is expressed as:rc=rucosθrusinθucosα,nc=−cosαcosθcosαsinθsinα

where ru=r0−usinα.

2.2 Conjugate Tooth Surface Generation

The meshing relationship between the wheel and pinion is established using coordinate transformations. The wheel surface r2 and normal vector n2 are mapped to the global coordinate system Sm:rm2=Mm2r2,nm2=Lm2n2

The pinion surface r1 is derived using the meshing equation f(u,θ,ϕ)=0:r1=M1mrm2,n1=L1mnm2

3. Ease-off Topology and Motion Simulation

3.1 Ease-off Surface Construction

The ease-off surface quantifies deviations between the theoretical and modified tooth surfaces. Key parameters include:

- Contact Path: Trajectory of instantaneous contact points.

- Differential Curvature: Determines contact ellipse dimensions.

- Transmission Error (TE): Reflects kinematic accuracy.

Table 1: Geometric Parameters of High Reduction Hypoid Gear

| Parameter | Pinion | Wheel |

|---|---|---|

| Number of Teeth | 3 | 60 |

| Face Width (mm) | 28.979 | 20 |

| Midpoint Spiral Angle (°) | 72 | 32.8983 |

| Pitch Cone Angle (°) | 10.9919 | 75.8605 |

| Offset Distance (mm) | 40 | — |

Table 2: Cutting Parameters for High Reduction Hypoid Gear

| Parameter | Pinion | Wheel (Concave/Convex) |

|---|---|---|

| Curvature Parameter a1 | — | 0.014 |

| Tool Tip Radius (mm) | 37.6 | 37.4 |

| Pressure Angle (°) | 20.5 | 19.0 |

| Radial Blade Position S (mm) | 51.9712 | 53.1513 |

3.2 Motion Simulation Results

- Unmodified Gears: Edge contact occurs at the tooth tip/root.

- Modified Gears: Contact shifts to the mid-face near the toe, forming an elliptical pattern.

- Overlap Ratio: Simulations confirm 5+ overlapping teeth, aligning with TE analysis.

4. Dynamic Performance Validation

4.1 Rolling Test and Contact Pattern Analysis

Post-grinding rolling tests on a Y9550 machine reveal:

- Contact Zone: Centered near the toe, avoiding edge contact.

- Consistency: Actual contact patterns match simulation predictions.

4.2 Vibration Characteristics

Vibration tests under varying loads (50 N·m, 200 N·m) and speeds (710–2100 rpm) demonstrate:

- Dominant Frequencies: 2× meshing frequency (141 Hz at 1410 rpm) exhibits peak amplitudes.

- Load Impact: Higher loads reduce vibration amplitudes due to increased stiffness.

Table 3: Vibration Acceleration Amplitudes (Vertical Direction)

| Condition | 50 N·m | 200 N·m |

|---|---|---|

| 710 rpm | 0.221 m/s² | 0.158 m/s² |

| 1410 rpm | 0.443 m/s² | 0.159 m/s² |

| 2100 rpm | 0.867 m/s² | 0.642 m/s² |

5. Key Findings and Innovations

- Tool Modification Strategy: Wheel tool parabolic correction enables point contact, simplifying pinion machining.

- Ease-off Optimization: Controlled ease-off topology minimizes edge contact and transmission error.

- Dynamic Stability: high reduction hypoid gear exhibit superior load-bearing capacity and vibration damping.

6. Conclusion

This study validates a systematic approach for designing and manufacturing high-performance high reduction hypoid gear.

- Optimal Contact Patterns: Eliminating edge contact while maintaining high overlap ratios.

- Manufacturing Efficiency: Simplified pinion machining parameters.

- Robust Dynamic Performance: Stable operation under extreme speed/load conditions.

Future work will focus on multi-objective optimization of ease-off surfaces for noise reduction and fatigue life enhancement.