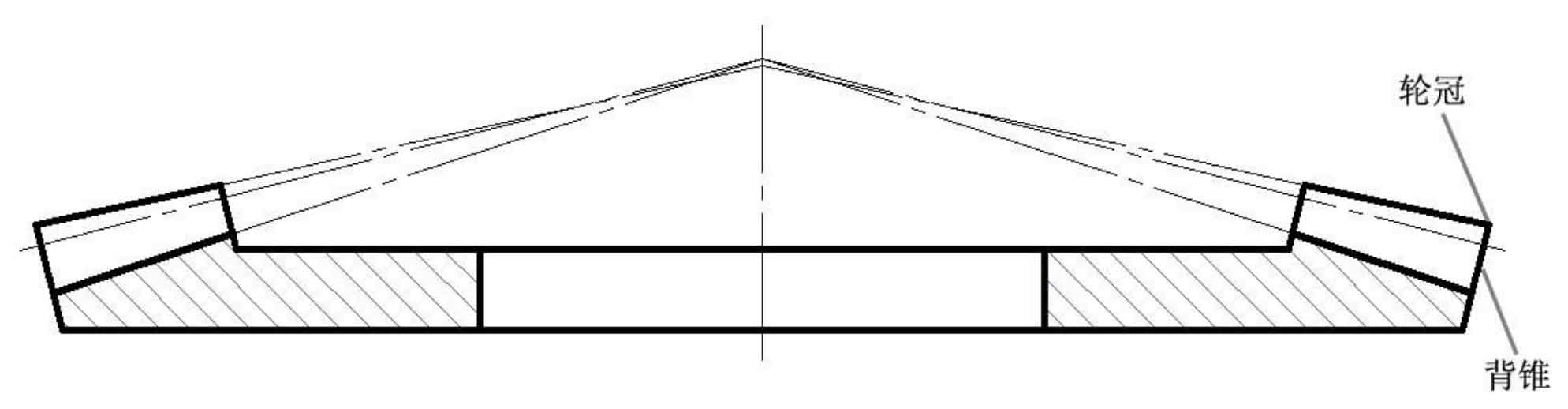

According to the characteristics of the forging process, the tooth profile of the spiral bevel gear is trimmed, which is conducive to forging forming and forging die drawing. As shown in Figure 1, the CAD drawing of large wheel milling is shown. In the milling tooth modeling of the spiral bevel gear, the existence of back cone makes the gear crown of the spiral bevel gear with the largest axial diameter, according to the forging die drawing process, The component die surface should be set at the place with the largest diameter, but there is a tooth shape there. Setting the parting surface requires the upper and lower dies to process the tooth cavity at the same time, which is troublesome and difficult to achieve. It is unfavorable to the forging accuracy and can be modified.

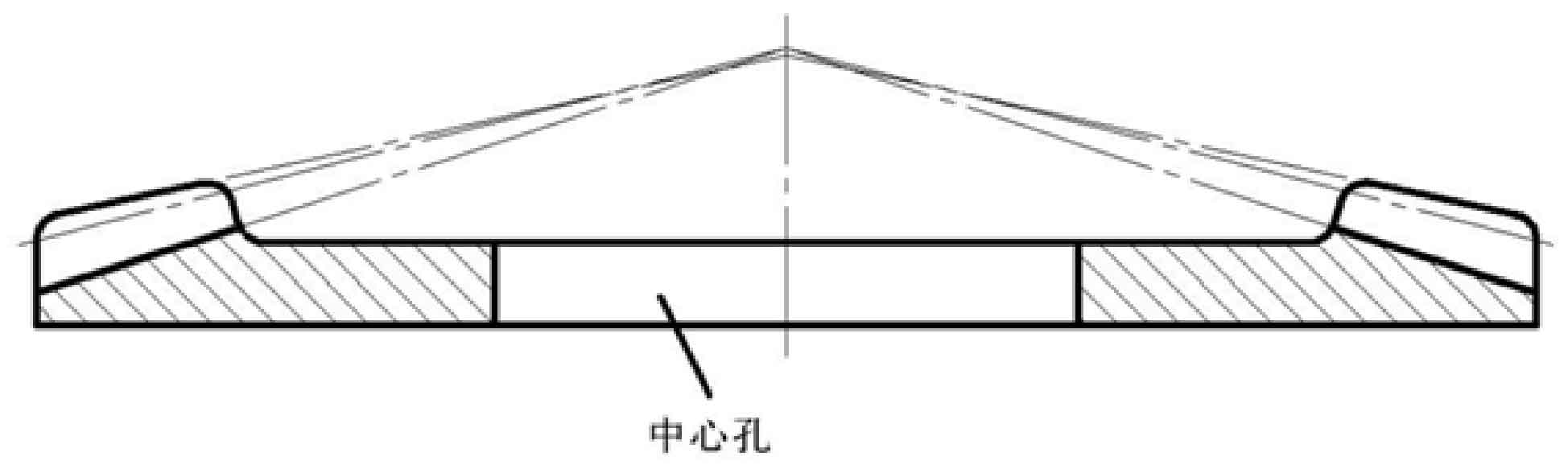

By modifying the back cone, the back cone becomes parallel and axial or reverse design, and the fillet transition is carried out at the sharp corner of the tooth top. The CAD model of the modified wheel blank is shown in Fig. 2. The precision forging of the modified spiral bevel gear will be conducive to the blank filling the die cavity and the forging out; The size of the center hole can be adjusted as needed. For example, in the example, the center hole can be expanded to the gear tooth position to reduce the forming volume and reduce the deformation resistance.