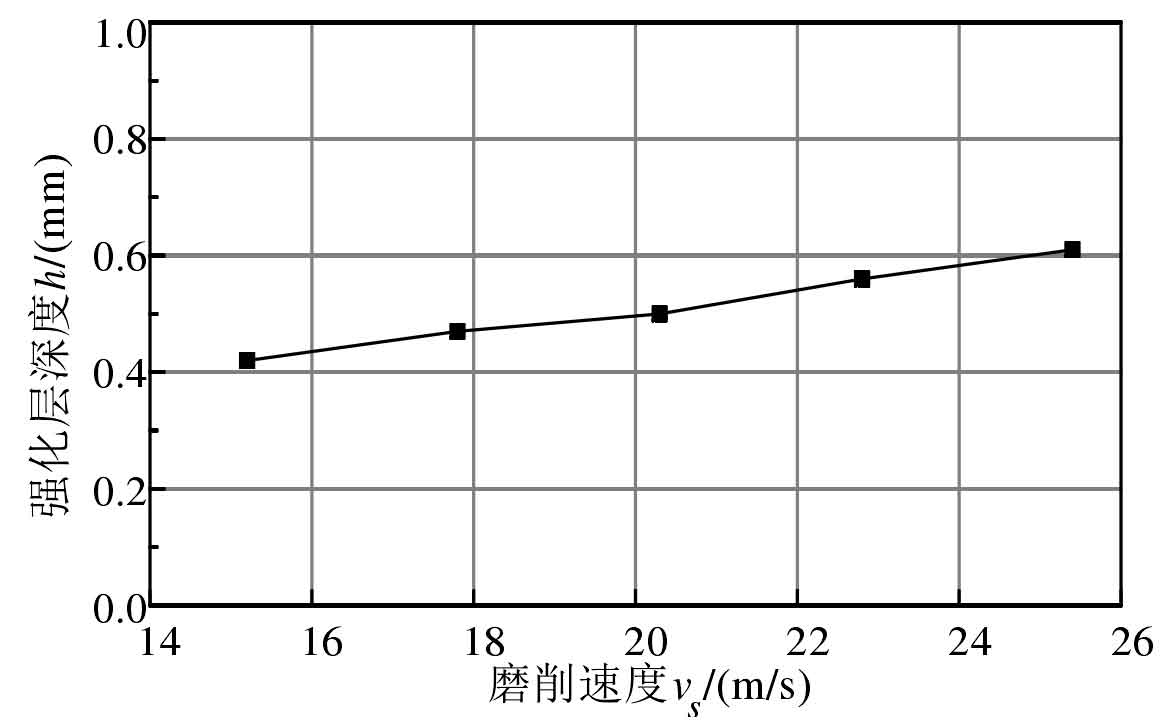

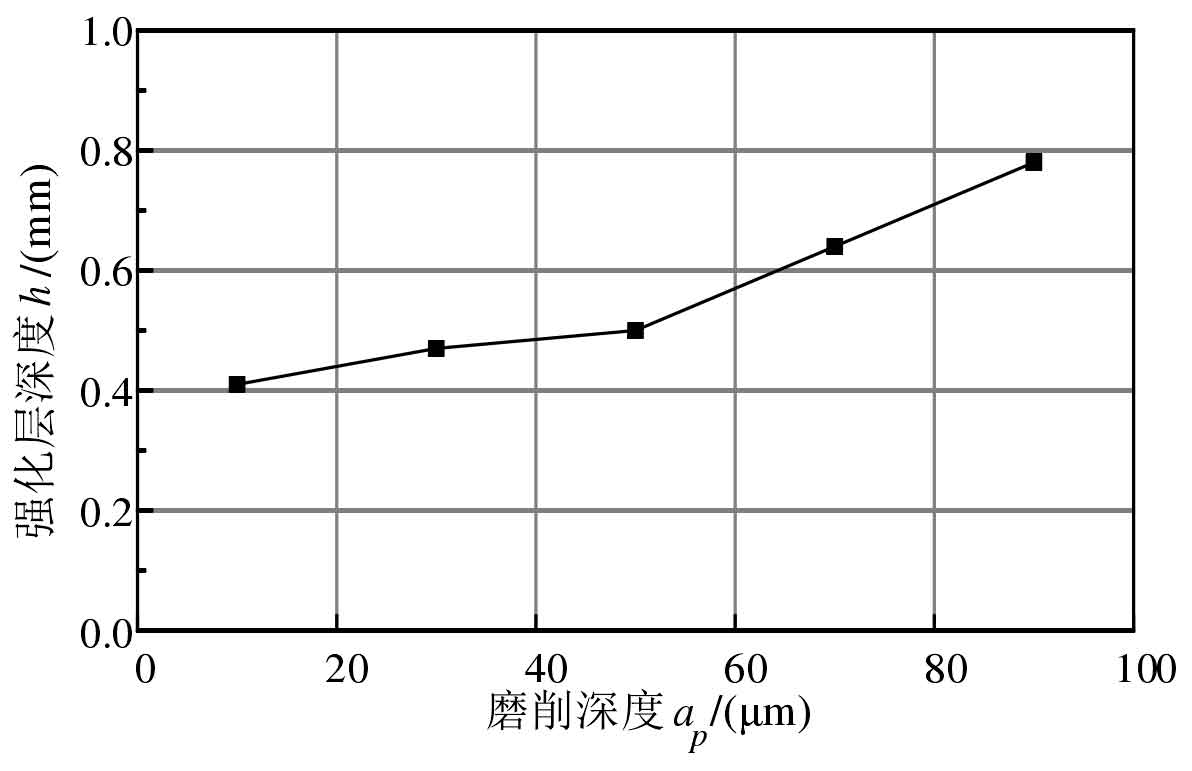

The depth value greater than the microhardness 685 HV of carburized layer is recorded as the strengthening layer depth, and the change trend of strengthening layer depth with grinding parameters is obtained, as shown in the figure.

It can be seen from figure (a) that the depth of strengthening layer increases with the increase of grinding depth. This is because the grinding depth increases, the contact arc length of the workpiece increases, the number of effective abrasive particles involved in grinding increases, and the undeformed cutting thickness of a single abrasive particle increases. These together lead to the increase of the energy transmitted to the workpiece and the increase of the thickness of the strengthening layer on the surface of the workpiece.

As can be seen from figure (b), when the grinding speed increases, the depth of the strengthening layer also increases. This is because the grinding speed increases, the number of effective abrasive particles participating in grinding per unit time increases, the cutting deformation energy increases, and the average undeformed cutting thickness of a single abrasive particle decreases, which intensifies the extrusion and friction, increasing the number of sliding friction of abrasive particles on the workpiece surface, resulting in increased friction and grinding heat, Finally, the thickness of the strengthening layer on the workpiece surface increases.

Therefore, in order to obtain a deeper strengthening layer and high surface hardness, the grinding depth and grinding speed can be appropriately increased, but the increase of grinding depth will lead to the increase of surface roughness, the aggravation of grinding wheel wear and serious grinding burn. Therefore, in order to obtain the best surface performance of gear steel 30crmnti after grinding, it is necessary to comprehensively consider all factors and select appropriate grinding parameters.