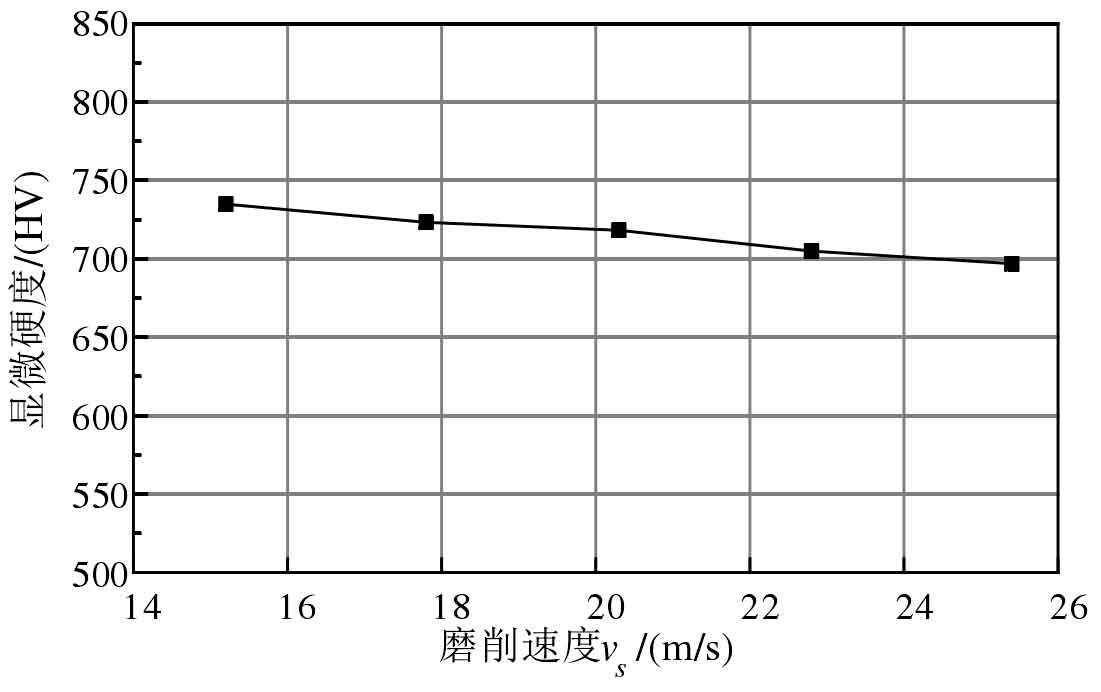

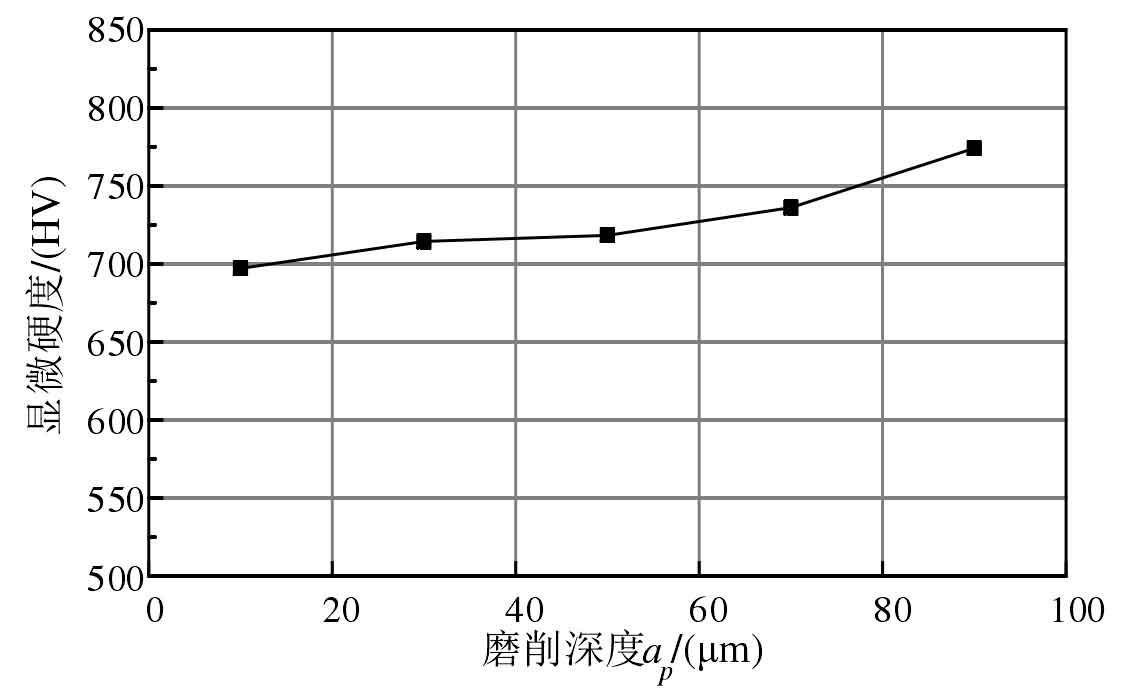

The microhardness of workpiece grinding surface corresponding to different grinding speed and grinding depth of spiral bevel gear steel is shown in the figure.

It can be seen from the figure that the surface microhardness of spiral bevel gear steel after grinding is higher than that before grinding, and the hardening degree is between 2% ~ 13%. Moreover, due to the presence of residual austenite on the surface, the grinding surface hardness of spiral bevel gear steel is slightly lower than the maximum hardness in the strengthening layer. When other parameters remain unchanged, the surface microhardness decreases with the increase of grinding speed, and increases with the increase of grinding depth.

This is because as mentioned above, there are two factors affecting the surface hardening in the grinding of spiral bevel gear steel. On the one hand, the plastic deformation caused by grinding force will distort the lattice, elongate or even break the grains, which will improve the surface hardness of the workpiece after grinding. On the other hand, the grinding heat of spiral bevel gear steel will restore and recrystallize the plastic deformation, lose the work hardening, and form the softening effect. However, if the temperature in the grinding area is too high and exceeds the phase transformation temperature of the material, the workpiece surface will be subject to secondary quenching. According to the microstructure analysis, the needle martensite formed after grinding of this spiral bevel gear steel is fine and has high hardness, which greatly improves the microhardness of the workpiece surface.

Figure (a) shows the test results of grinding speed on microhardness. When the grinding speed of spiral bevel gear steel increases, the average undeformed cutting thickness of a single abrasive grain decreases, which reduces the grinding force on each abrasive grain. The reduction of grinding force of spiral bevel gear steel leads to the reduction of plastic deformation, the reduction of cold work hardening degree and the corresponding reduction of hardening degree. At the same time, with the increase of grinding speed, the number of working abrasive particles per unit time increases, which intensifies the extrusion and friction, increasing the number of sliding friction of abrasive particles on the workpiece surface, resulting in the increase of grinding heat of spiral bevel gear steel and the corresponding softening effect. However, under different grinding parameters, the surface microstructure has little difference, and the hardness difference caused by microstructure is small. These reasons together lead to the decrease of microhardness of workpiece surface.

Figure (b) shows the test results of grinding depth on microhardness of spiral bevel gear steel. When the grinding depth increases, the microhardness increases. This is because with the increase of grinding depth, the number of effective abrasive particles participating in the grinding of spiral bevel gear steel increases, the undeformed cutting thickness of a single abrasive particle increases, and the contact arc length of the grinding wheel increases. These together lead to the increase of grinding deformation force and friction force in the grinding process, so the grinding force and grinding heat increase accordingly. The increase of grinding force of spiral bevel gear steel increases the plastic deformation of workpiece surface and the degree of cold work hardening. Compared with the softening effect of grinding heat of spiral bevel gear steel, it plays a leading factor, so it finally leads to the enhancement of work hardening. Therefore, from the perspective of improving the surface microhardness of gear steel 30crmnti after grinding, the grinding depth can be appropriately increased and the grinding speed can be reduced.