In gear meshing drive, in order to avoid jamming, clearance between tooth profiles must be left, which is an important factor for no-load knocking of gear transmission system.Side clearance can be changed by adjusting the length of the common normal or the center distance.

The influence of tooth side clearance change and center distance deviation change caused by common normal adjustment on dynamic load under no-load condition is studied respectively.It can be seen from the analysis that the variation of center distance deviation also causes the variation of several meshing parameters, such as tooth side clearance, meshing angle and meshing rigidity.

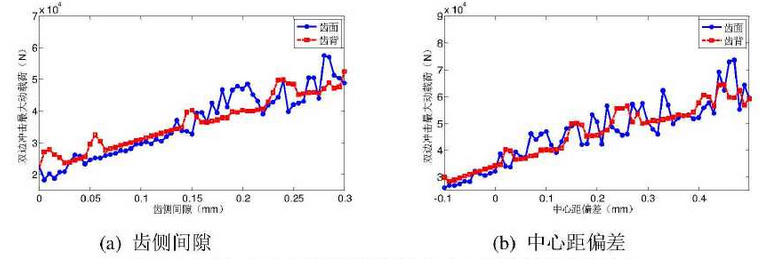

The range of tooth side clearance is [0,0.3mm], and the interval is 0.005mm.The range of center distance deviation is [-0.1mm, 0.5mm], and the interval is 0.01mm.The variation trend of the maximum engagement force with the side clearance and center distance deviation is shown in the figure.It can be seen from the diagram that the tooth side clearance and center distance deviation have a great influence on the maximum dynamic load of the gear under no-load condition.

With the increase of backlash or center distance deviation, the maximum impact load on tooth surface and back shows an increasing trend on the whole, but there are local peaks under individual parameters.Under different backlash, the maximum dynamic loads of tooth surface and back are 57480N and 52390N respectively, which are 1.6 times and 1.86 times higher than the minimum dynamic loads of 22070N and 18310N respectively.Under different center distance deviations, the maximum dynamic loads on tooth surface and back were 73720N and 64390N respectively, which increased by 1.85 times and 1.26 times compared with the minimum dynamic loads of 25900N and 28480N respectively.

The variation trend of the root mean square value of engagement force with the tooth side clearance and center distance deviation is shown in the figure.It can be seen from the diagram that the root mean square value of dynamic meshing force of gears increases approximately linearly with the increase of backlash or center distance deviation.difference

Under the backlash, the maximum and minimum RMS of dynamic load are 7398N and 4458N, respectively, with an increase of 66%.Under different center distance deviations, the maximum and minimum root mean square values of dynamic loads are 8713N and 5034N, respectively, with an increase of 73%.From the above analysis, it can be seen that in the design and assembly of gear drive system, the backlash and center distance deviation should be minimized to reduce the dynamic load under no-load condition without jamming.