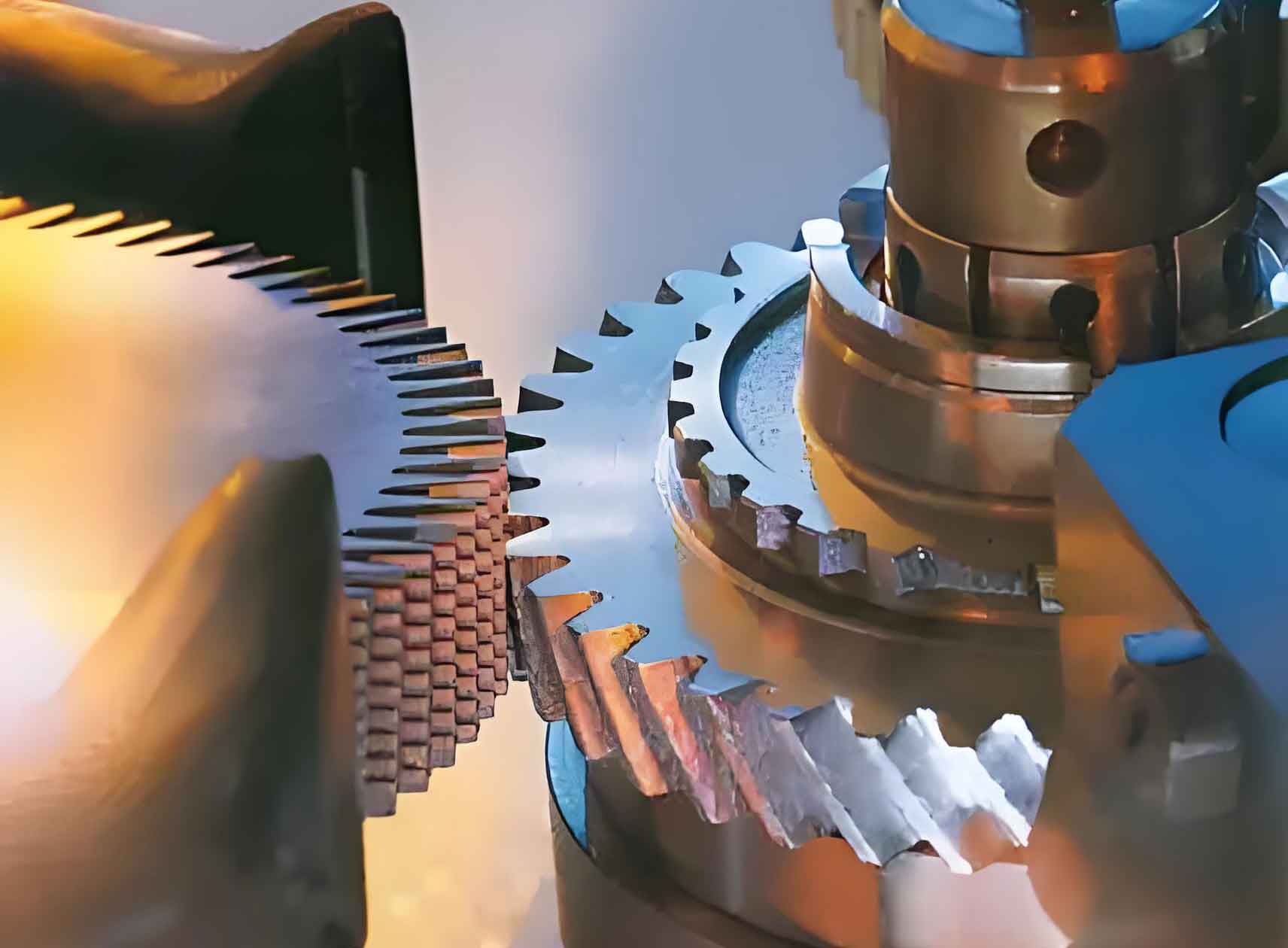

Gear manufacturing stands as the largest industry within the realm of machinery fundamental components. With the rapid advancement of China’s equipment manufacturing capabilities, the demands for gear processing precision and efficiency have escalated significantly. The continuous adoption of advanced CNC equipment has catalyzed transformative changes in cutting processes and technologies. As a core element in gear finishing, gear shaving is extensively employed across various gear types, ranging from small gears used in automobiles, reducers, and agricultural machinery to large reduction gears for marine turbines. The evolution of advanced gear shaving technology is intrinsically linked to developments in cutting fluid technology. Consequently, the judicious selection of cutting fluids in production is paramount. During gear shaving, a substantial portion of energy dissipates through friction at the tool-chip and tool-workpiece interfaces. Thus, metal cutting fluids must exhibit superior lubrication, rust prevention, cleaning, and cooling properties.

Traditional oil-based cutting fluids suffer from inadequate cooling performance. During high-speed cutting operations, excessive heat generation elevates temperatures in the cutting zone, leading to smoke, fire hazards, and thermal deformation of workpieces that compromise machining accuracy. In contrast, water-based cutting fluids offer superior thermal conductivity, cleaning efficiency, and cost-effectiveness due to aqueous dilution. They also enhance workplace safety and hygiene. With the ongoing depletion of non-renewable resources like petroleum, research and development into water-based cutting fluids present a promising trajectory.

This research centers on cutting fluids, using the gear shaving process as the investigative platform. We propose transitioning from oil-based to water-based cutting fluids to achieve greener machining processes and minimize environmental pollution. First, based on the characteristics of gear shaving and the roles and classifications of cutting fluids, we conduct physicochemical tests on preselected fluids and outline selection methodologies tailored to diverse machine tools, tools, materials, and operations. Second, comparative gear shaving experiments employing different cutting fluid types analyze outcomes across workpiece quality, tool life, cost, and resource/environmental impact. Finally, leveraging experimental results, we employ fuzzy comprehensive evaluation to assess machining outcomes. A decision-making model optimizing cutting fluid selection for green manufacturing is proposed, integrating five objectives: processing time (T), quality (Q), cost (C), resource consumption (R), and environmental impact (E). This model provides a theoretical foundation for the eco-conscious selection of gear shaving cutting fluids.

Gear Shaving Fundamentals and Green Cutting Fluids

Gear shaving, a critical gear finishing technique first applied in the USA in 1926, offers advantages over grinding, including higher efficiency, lower cost, and absence of surface burns or cracks. Consequently, it is widely utilized in batch production for automotive, tractor, and machine tool gears.

Gear Shaving Machines and Tools: Gear shaving machines perform precision finishing on cylindrical gears. For gears requiring Grade 6 or higher accuracy, or post-hardening finishing, shaving follows roughing operations like hobbing or shaping. It effectively reduces surface roughness, corrects profile and lead deviations, and enhances overall gear precision, typically achieving Grades 6-7 with surface roughness Ra of 0.8-0.4 μm.

Gear shaving machines are categorized by layout:

- Horizontal Gear Shaving Machines: Feature horizontal axes for tool and workpiece. Sub-types include tool-above-workpiece (compact, suited for mass production of small/medium gears) and tool-behind-workpiece (facilitates workpiece loading/unloading, ideal for large gears/shaft gears). The shaving cutter, mounted on the main spindle, rotates bidirectionally. The workpiece, fixed between centers on the worktable, rotates freely via meshing with the cutter.

- Vertical Gear Shaving Machines: Feature vertical axes, primarily for large gears in locomotive, mining, and marine sectors. Unlike horizontal machines, large vertical types often employ workpiece-driven cutter rotation with axial tool movement. Radial feed is used for double-flank shaving; single-flank shaving requires applying a braking torque to the cutter spindle.

The predominant tool is the disk-type shaving cutter, resembling a high-precision helical gear with small grooves along the involute direction on its tooth flanks, forming cutting edges. During operation, these edges remove minute amounts of material (0.005–0.01 mm), improving surface finish and accuracy. Disk cutters are classified as Grade A or B for finishing Grade 6 or 7 gears, respectively. A single disk cutter can process gears with different tooth counts if the module matches. Common helix angles are 5°, 10°, and 15° (5° suits gears with shoulders or multi-step gears). Cutters have left- or right-hand helix directions, opposite to the workpiece helix.

Arbor precision critically affects workpiece accuracy. Key arbor requirements include:

$$ \text{Radial runout} \leq 0.003 \, \text{mm}, \quad \text{End face runout} \leq 0.005 \, \text{mm} $$

$$ \text{Fit clearance with gear bore} \rightarrow \text{Minimal} $$

$$ \text{Proper mounting tension and alignment using precision centers} $$

$$ \text{Gear bore tolerance: H6, H7, H8; Arbor diameter tolerance: h5} $$

Principles and Methods of Gear Shaving: Gear shaving relies on the relative sliding motion generated during the crossed-axis helical gear engagement between the shaving cutter and the workpiece. The cutter, essentially a hardened, high-precision helical gear with serrated cutting edges, removes material through this sliding action. The essential motions are:

- Cutter high-speed bidirectional rotation (primary motion).

- Workpiece rotation driven by cutter meshing (free rotation).

- Radial feed per worktable stroke cycle (to achieve full tooth depth).

The relative sliding speed (V_w), the cutting velocity, arises from the axis crossing angle (Σ):

$$ V_w = V_1 \frac{\sin \Sigma}{\cos \beta_2} = V_{2t} – V_{1t} $$

where \( V_1 \), \( V_2 \) are the pitch line velocities of cutter and workpiece, \( V_{1t} \), \( V_{2t} \) are their tangential components, \( \beta_1 \), \( \beta_2 \) are their helix angles, and \( \Sigma = |\beta_1 \pm \beta_2| \) (sum for same hand, difference for opposite hand). Larger Σ increases V_w and shaving efficiency.

Common gear shaving methods include:

| Method | Principle Diagram | Motion | Advantages | Disadvantages |

|---|---|---|---|---|

| Axial | Workpiece reciprocates axially | Cutter rotates; Workpiece reciprocates axially; Radial feed per stroke; Final strokes without feed. | Can shave crowned gears via machine crowning mechanism; Suitable for wide gears. | Long stroke length, numerous strokes reduce productivity and tool life; Localized cutter wear. |

| Diagonal | Workpiece fed at angle ω to axis | Workpiece fed along a direction angled ω to its axis. | Can machine flanged/stepped gears; Shorter stroke length benefits gears ≤50mm; Continuous node shift improves tool life. | Higher cutter precision required; Unsuitable for very wide gears; Cutter width must increase with gear width. |

| Tangential | Workpiece fed tangentially | Cutter fed tangentially relative to workpiece. Radial feed constant for small stock; Multiple strokes with radial feed for large stock. | Can shave flanged/multi-step gears; Short stroke; Uniform tool wear; Simple motion. | Modified cutter needed for crowning; Cutter width > gear width; Inferior surface quality. |

| Radial | Purely radial feed | Purely radial feed; No axial feed. Cutter serrations arranged in staggered pattern. | Can shave double-step/flanged gears; Large contact area improves lead/profile accuracy; High efficiency; Reduced tool wear. | Modified cutter needed for crowning/taper. |

Radial gear shaving excels in efficiency, accuracy, tool life, and economy, enabling the machining of double-step gears unachievable via axial methods. Axial shaving typically yields Grade 7.5 accuracy, while radial shaving achieves Grade 6.

Cutting Parameter Selection: Key parameters influencing gear shaving include:

- Cutting Speed (V_w): Governed by cutter rotational speed (n₀). Higher speeds improve surface finish but accelerate tool wear. Optimal ranges depend on workpiece material:

$$ n_0 = \frac{1000 V_0}{\pi m z_0} \, \text{(r/min)}, \quad n = \frac{z_0 n_0}{z} \, \text{(r/min)} $$

where \( z_0 \), \( z \) are cutter and workpiece teeth numbers, \( V_0 \) is cutter pitch line velocity.Workpiece Material Carbon Steel Alloy Steel Cast Iron Hardness HBS 170 196 217 285 229 210 V (m/min) 150 140 130 80 105 80 - Feed Rates:

- Longitudinal Feed (f): Expressed as feed per workpiece revolution (f, mm/rev) or worktable feed rate (vf, mm/min), related by \( v_f = f n \). Higher vf increases productivity but degrades accuracy and surface quality. Selection depends on gear precision:

- Radial Feed (fr): Critical for correcting pre-shaving errors. Insufficient fr fails to remove stock; excessive fr overloads machine/tool, damages accuracy, and accelerates wear. Start with maximum fr, decrease gradually, finish with 2-4 spark-out strokes.

Gear Grade Surface Roughness (μm) Teeth Number f (mm/rev) Radial Feed/Stroke (mm) 6 ≥Ra0.63 17 25 40 100 0.02-0.025 Ra1.25 0.15-0.20 0.20-0.25 0.25-0.30 0.35-0.40 7 >Ra0.63 0.15-0.20 0.20-0.25 0.25-0.30 0.35-0.40 0.04-0.05 Ra1.25 0.20-0.30 0.25-0.30 0.35-0.40 0.50-0.60 - Stroke Count: Includes cutting strokes (determined by stock and fr) and finishing strokes (critical for surface roughness, typically 4-6 for Grade 6, 2-4 for Grade 7).

- Stock Allowance (Δs, ΔH): Minimize stock to reduce tool wear and workload, yet ensure adequate correction of pre-shaving errors. Relationship at α=20°:

$$ \Delta H = 1.37 \Delta s $$Module Range Δs (mm) <1 0.011~0.029 1.5~1.7 0.018~0.037 1.75~2.5 0.029~0.044 2.5~3 0.037~0.066 Large Module

Gear Dia (mm)<100 100-200 200-500 500-1000 >1000 3~5 0.08-0.12 0.10-0.15 0.12-0.18 0.12-0.18 0.15-0.20 5~7 0.10-0.14 0.12-0.16 0.15-0.18 0.15-0.18 0.16-0.20 7~10 0.12-0.16 0.15-0.18 0.18-0.20 0.18-0.22 0.18-0.22

Green Cutting Fluids: Green manufacturing in gear shaving involves optimizing process parameters and sequences to minimize environmental impact and resource consumption (material, energy, tool wear, cutting fluid use). We focus on green cutting fluid selection and process parameter optimization.

- Cutting Fluid Selection: A qualitative-quantitative decision problem. Traditional selection prioritizes Time (T), Quality (Q), and Cost (C). Green manufacturing adds Resource consumption (R) and Environmental impact (E). The goal is minimizing T, R, C, E while maximizing Q. These interdependent objectives form the decision framework:

- Environmental Impact (E): Encompasses ecological effects (pollution from lifecycle stages), human health hazards (toxicity, skin/respiratory irritation), and safety risks (fire for oils, corrosion for water-based fluids).

- Process Parameter Optimization: Parameters like cutting speed and feed rates significantly influence tool life, surface quality, energy consumption, and environmental footprint. Optimization involves adjusting parameters within constraints to achieve optimal overall performance (e.g., minimizing energy while ensuring quality). Orthogonal experimental design is effective for exploring parameter combinations efficiently.

Physicochemical Properties and Selection Methodology of Cutting Fluids

Cutting fluids, essential adjuncts in machining, enter the cutting zone to improve lubrication and cooling. Objectives include extending tool life, ensuring part accuracy, enhancing surface finish, removing chips, cooling components, preventing rust, boosting efficiency, and reducing costs. Cutting fluids fulfill four primary functions: Cooling, Lubrication, Cleaning, and Rust Prevention.

Functions and Classification:

- Cooling: Transfers heat via convection/vaporization, preventing thermal deformation. Water excels due to high thermal conductivity (0.63 W/m·K), specific heat (4.18×10³ J/kg·K), latent heat (2260 J/g), and low viscosity (1.0 mm²/s) compared to oil (0.125–0.21 W/m·K, 1.67–2.09×10³ J/kg·K, 167–314 J/g, 20–300 mm²/s). Water-based fluids generally outperform oil-based in cooling. Increasing flow rate/pressure or using mist cooling enhances effectiveness.

- Lubrication: Reduces friction at tool-chip/workpiece interfaces by forming a thin film. Oil-based fluids, especially with lubricity/EP additives, generally offer better lubrication. Effective lubricants combine oiliness agents (fatty acids, alcohols, esters) and EP agents (Cl, S, P compounds).

- Cleaning: Removes chips/abrasives to prevent damage and maintain surface quality. Lower viscosity oils clean better. Water-based fluids with surfactants excel, as surfactants dislodge contaminants and prevent redeposition.

- Rust Prevention: Protects workpiece/machine from corrosion by moisture, oxygen, etc. Rust-inhibitive oils and some emulsions offer this; many synthetics only provide specific machining protection. Modern fluids often combine machining performance with rust prevention.

| Property | Oil-Based | Water-Based |

|---|---|---|

| Cooling | Poorer | Better |

| Lubrication | Better | Poorer |

| Cleaning | Poorer | Better |

| Rust Prevention | Better | Poorer |

Cutting fluids are classified as Oil-based or Water-based.

- Oil-Based: Primarily mineral oil. Types include:

- Straight Mineral Oils (e.g., kerosene, diesel): Good settling, low cost, stable, non-corrosive. Poor lubrication.

- Fatty Oils (Vegetable/Animal): Good for low-speed, light cuts. Prone to oxidation, scarce, largely replaced.

- Non-active EP Oils: Mineral oil + non-active EP additives (e.g., chlorinated oils). Good EP lubrication, stable, non-corrosive to non-ferrous metals.

- Active EP Oils: Mineral oil + reactive S-based additives. Excellent EP/anti-weld but corrosive to non-ferrous metals.

- Compound Oils: Mineral oil + lubricity/EP additives/vegetable oils. Better lubrication than straight oils but inadequate under severe conditions.

- Water-Based:

- Emulsions (Soluble Oils): Mineral oil (40-80%) + emulsifiers, rust inhibitors, etc. Form oil-in-water emulsions. Combine cooling and lubrication, cost-effective, safe. Prone to bacterial degradation, shorter life.

- Semi-synthetic Fluids (Microemulsions): Lower mineral oil content (5-30%) + surfactants, EP agents, etc. Dilute to translucent solutions. Better bacterial resistance than emulsions but prone to inorganic salt residue.

- Full Synthetic Fluids: No mineral oil. Comprise water-soluble EP agents, lubricants, rust inhibitors, surfactants. Dilute to transparent/semi-transparent solutions. Safe, long life, resource-efficient. A key future focus.

Physicochemical Performance Testing: Laboratory tests assess key properties of preselected fluids (Emulsion I, Microemulsion II, Synthetic III):

- Emulsion Stability: Tested per standard (e.g., GBT 6144-2010). 5g sample diluted to 100ml with water, shaken, pH measured, observed after 24h for oil/soap separation. Emulsion I and II showed excellent stability (no separation).

- Salt Tolerance: 0.5ml saturated NaCl added to 100ml of 15% dilution, shaken, stored 4h. Microemulsion II and Synthetic III passed (no separation); Emulsion I failed (stratification).

- Defoaming: 70ml dilution shaken vigorously for 1min, foam height measured after 10min. All passed (≤2ml residual foam). Synthetic III performed best (foam vanished in 1min).

- Maximum Non-Seizure Load (PB Value): Measured via Four-Ball Test (GB/T 3142-1982). Higher PB indicates better lubricity/EP performance.

Fluid PB (N) Microemulsion II 510 Synthetic III 620 - Surface Tension: Measured by ring method (GB/T 6541-86). Lower tension enhances wettability/cooling.

Fluid Surface Tension (mN/m) Microemulsion II 28 Synthetic III 25 - Rust Prevention: Gears immersed in dilutions (10%, 15%, 20%, 25%), withdrawn, exposed, monitored for rust spots. All concentrations exhibited excellent rust prevention (>14 days). pH decreased gradually then stabilized; minor temp/humidity variations had negligible impact.

- Paint Compatibility: Coated cast iron panels half-immersed in fluid for 21 days (GBT 6144-2010). Inspected weekly for blistering, peeling, cracking. All fluids passed. New anti-rust paint outperformed standard paint (less gloss loss).

Cutting Fluid Selection Methodology: Selection involves choosing between oil/water-based, then specific type based on application.

- Machine Tool Requirements: Consider machine design compatibility (seals, materials), precision level (high-precision/expensive machines may prefer oils or high-performance synthetics), and lubrication system integrity (prevent cross-contamination). Prioritize high rust prevention.

- Tool and Workpiece Material:

- Tool Material: HSS tools (high heat ~600°C) need good cooling (water-based). Carbide tools (very high heat ~1000°C) require careful fluid selection; use flood cooling. Ceramic tools generally avoid fluids or use carefully.

- Workpiece Material:

- Cu/Al/Mg alloys: Can use dry or light fluids. Aluminum needs neutral/slightly acidic fluids.

- Cast Iron: Often dry machined; graphite acts as lubricant. Grinding/planing may use kerosene/sulfurized oils.

- Low/Medium Carbon & Alloy Steels: Low-carbon steels (high ductility) need higher viscosity active oils for hobbing/shaving. Medium-carbon steels use EP emulsions/active oils.

- High-Temperature Alloys: Require excellent lubrication/cooling.

- Operation Type: Machining difficulty influences fluid choice:

- Roughing: High stock, speed, feed. Prioritize cooling (emulsions, synthetics).

- Finishing: High precision/surface quality demands. Balance lubrication/cooling based on tool material and speed. HSS tools at low speed (<10 m/min) need good lubrication; medium speed (10-30 m/min) need balance; high speed (>30 m/min) need cooling (EP synthetics/microemulsions).

Machining Performance Testing of Gear Shaving Cutting Fluids

Real-world machining tests are indispensable for evaluating cutting fluid performance. We employed a “process rhythm” approach on a production line (Chongqing Machine Tool Group), maintaining identical conditions (machine: YDA4232CNC, tool: disk cutter, workpiece: 20CrMo auto gear, parameters: n=180 rpm, vf=0.8 mm/min, fr=0.08 mm) while varying cutting fluids: Oil-based, Domestic Microemulsion II, Imported Synthetic III.

Test Conditions:

- Machine: YDA4232CNC CNC Precision Gear Shaving Machine (Max Ø320mm, Max module: axial 6/radial 4).

- Tool: Disk Shaving Cutter (M35 HSS, mn=2.25, α=20°, β=15°R, Ø170.05mm, z=73).

- Workpiece: Auto Transmission Gear (20CrMo, mn=2.25, α=20°, β=25°L, z=32).

- Inspection: CNC3903A Gear Tester.

- Fluids:

Property Oil-Based Microemulsion II Synthetic III Appearance (Conc.) Transparent Red-Brown Transparent Light Green Transparent Light Brown Kin. Viscosity (mm²/s) 11 – – Flash Point (°C) 180 – – PB (N) 980 510 550 Dilution pH – 8.6 9.0 Defoaming (ml/10min) – 2 0.5 Surface Tension (mN/m) – 28 32

Results and Analysis:

- Workpiece Quality: Sampled parts measured for surface roughness (Ra) and profile slope deviation (fHα).

- Surface Roughness: Synthetic III provided the most stable and best surface finish over the tool life, followed by Microemulsion II. Oil-based fluid showed the largest Ra increase with part count.

- Profile Slope Deviation: All fluids showed initial improvement then degradation. Microemulsion II exhibited the largest deviation increase, exceeding tolerance (≤11 μm) at ~5500 parts. Synthetic III showed the most stable performance.

- Tool Life: Measured by parts machined per tool grind (tool life = parts per grind × regrinds + 1). Oil-based fluid yielded the highest tool life (6530 parts/grind, ~137k part life). Synthetic III performed better than Microemulsion II (6110 vs 5560 parts/grind, ~128k vs ~117k part life). Water-based fluids did not improve tool life under these conditions; Microemulsion II induced faster wear.

- Environmental Impact & Cost:

- Environmental Impact: Includes ecological damage (waste oil/fluid pollution), human health hazards (toxicity, skin/respiratory irritation), and safety (oil fire risk, water-based fluid corrosion). Water-based fluids eliminate fire risk and are generally easier/safer to treat (filtration, chemical/biological treatment) than oils.

- Cost Analysis: Calculated cost per part based on fluid price, concentration, and consumption rate.

Fluid Type Conc. Price (Conc.) Diluted Vol. Diluted Price/L Consumption/Part (L) Cost/Part (¥) Oil-Based 100% ¥3400/180L 180L ¥18.9 0.0047 0.09 Microemulsion II 15% ¥670/18L 120L ¥5.6 0.0051 0.028 Synthetic III 15% ¥1600/18L 120L ¥13.3 0.0053 0.07 Domestic Microemulsion II offered the lowest cost per part (¥0.028). Imported Synthetic III cost more (¥0.07) but provided better quality/tool life than Microemulsion II. Oil-based was costliest (¥0.09).

Usage and Management: Proper maintenance is crucial for performance and longevity.

- Oil-Based Fluids: Regularly top-up; replace entirely every 6-12 months. Prevent contamination by other oils/lubricants and water ingress. Use magnetic separators/filters for chip removal. Monitor viscosity, flash point, acid number, water content.

- Water-Based Fluids: Critical control parameters:

- Concentration: Monitor via refractometer. Too low: poor lubrication/rust prevention; too high: foaming, skin irritation, waste.

- Microbial Control: Use clean water (preferably deionized/softened for makeup). Use biocides if necessary.

- pH Control: Maintain pH 8.0-9.5. Falling pH indicates bacterial growth; rising pH may cause skin issues. Use pH adjusters.

Monitor appearance, stability, conductivity, foam, bacteria count.

Green Manufacturing-Oriented Evaluation and Optimization for Gear Shaving Cutting Fluids

Fuzzy comprehensive evaluation (FCE), based on fuzzy mathematics, effectively handles qualitative-quantitative problems like cutting fluid selection under multiple conflicting objectives (T, Q, C, R, E).

Evaluation Methodology: The target system comprises five decision objectives: Time (T), Quality (Q), Cost (C), Resource Consumption (R), Environmental Impact (E). The FCE steps are:

- Define factor set U = {u₁, u₂, …, uₘ} (evaluation aspects). Subdivide aspects into criteria sets uᵢ = {uᵢ₁, uᵢ₂, …, uᵢₙ}.

- Define evaluation set V = {v₁, v₂, …, vₚ} (e.g., Good, Fair, Poor).

- Establish fuzzy relation matrix R for each aspect/criterion, where element rᵢⱼ is the membership degree of factor i to grade j.

- Assign weights A = (a₁, a₂, …, aₘ) for aspects, Aᵢ = (aᵢ₁, aᵢ₂, …, aᵢₙ) for criteria, satisfying ∑a=1.

- Compute comprehensive evaluation vector B = A ∘ R = (b₁, b₂, …, bₚ) using fuzzy composition (e.g., weighted average).

- Calculate overall score: Score = 100 × B ∙ U, where U is the grade score vector (e.g., [0.9, 0.6, 0.3]).

Case Study: Apply FCE to the three gear shaving fluids tested. Define X = [x₁, x₂, x₃] where xᵢ=1 selects fluid i (Oil, Microemulsion II, Synthetic III). The model seeks X* optimizing [T(X), Q(X), C(X), R(X), E(X)].

Define U, V, weights, and R matrices based on experimental data and expert judgment (Table 5.1 summary). Calculate B for each fluid:

- Oil-Based (A1): B = A ∘ R = (0.6458, 0.2220, 0.1324). Score = 75.41.

- Microemulsion II (A2): B = (0.6534, 0.2305, 0.1189). Score = 76.20.

- Synthetic III (A3): B = (0.7296, 0.1876, 0.1098). Score = 80.21.

| Fluid | Comprehensive Evaluation Vector (B) | Score |

|---|---|---|

| Oil-Based | (0.6458, 0.2220, 0.1324) | 75.41 |

| Microemulsion II | (0.6534, 0.2305, 0.1189) | 76.20 |

| Synthetic III | (0.7296, 0.1876, 0.1098) | 80.21 |

Synthetic III scored highest, demonstrating superior overall green performance. Microemulsion II offered a cost-effective alternative with better performance than oil.

Optimization of Cutting Fluid System:

- Limitations of Traditional Systems: Single-machine systems suffer high costs, incomplete filtration (chip accumulation), and resource waste (imprecise delivery, inefficient recycling).

- Centralized System Optimization: Implement for large-scale production:

- Three-Stage Filtration: Settling → Vacuum → Back-flush ensures fluid cleanliness.

- Temperature Control: Maintain fluid at 23±1°C (chilling in summer, heating in winter).

- Supply/Return: Overhead main lines feed machines; return lines collect used fluid for centralized treatment/recycling.

Process Parameter Optimization: After fluid selection, optimize cutting parameters (cutter speed A, feed rate B, feed amount C) via orthogonal array L9(3³) to minimize T, R, C while ensuring Q, using Synthetic III. Levels: A=[180, 200, 220] rpm, B=[0.8, 0.9, 1.0] mm/min, C=[0.08, 0.09, 0.10] mm. Analyze results (surface quality, tool wear, energy) to determine optimal combination (AᵢBⱼCₖ).

Conclusion and Outlook

This research demonstrates the viability and advantages of transitioning to water-based cutting fluids for gear shaving, aligning with green manufacturing principles. Key findings include:

- Water-based fluids, particularly high-performance synthetics, offer superior cooling, leading to better surface finish and reduced thermal distortion compared to oil-based fluids.

- While the tested water-based fluids did not extend tool life beyond the oil-based fluid under the specific conditions, the imported synthetic fluid showed better tool life stability than the domestic microemulsion.

- Water-based fluids significantly enhance workplace safety (no fire risk), ease waste treatment, and reduce operational costs, with the domestic microemulsion offering the lowest cost per part.

- The Fuzzy Comprehensive Evaluation model, integrating T, Q, C, R, E, effectively ranked the fluids: Synthetic III (80.21) > Microemulsion II (76.20) > Oil-based (75.41), validating the holistic green performance of selected water-based options.

- Centralized fluid systems with multi-stage filtration and temperature control, coupled with process parameter optimization via orthogonal experiments, offer pathways for further efficiency and sustainability gains.

Future work should focus on:

- Developing simpler, standardized test protocols for rapid cutting fluid performance assessment in gear shaving.

- Conducting rigorous experimental validation of the proposed orthogonal array-based process parameter optimization for Synthetic III.

- Enhancing the comprehensiveness and granularity of the green evaluation model, incorporating lifecycle assessment (LCA) metrics and exploring AI-driven optimization.

- Researching next-generation biodegradable additives and more efficient, closed-loop fluid recycling/minimization technologies to further reduce environmental footprint.

The shift towards high-performance, environmentally responsible water-based cutting fluids represents a critical step for sustainable advancement in gear manufacturing.