The efficient processing of agricultural by-products, such as soybean meal, into high-quality animal feed is a critical task in modern agriculture. The twin-screw extruder stands as a cornerstone machine in this field, valued for its superior mixing, shearing, and conveying capabilities compared to single-screw counterparts. However, a persistent challenge lies in optimizing the mixing homogeneity within the extruder barrel. Conventional twin-screw designs often exhibit limitations where material transport is too efficient, leading to insufficient residence time and shear, which ultimately compromises the final product’s uniformity and quality. This study addresses this fundamental performance gap by introducing a novel screw design that integrates a cycloidal drive reduction unit and a reverse-flight section to actively manipulate flow dynamics and enhance mixing performance.

The core innovation lies in the strategic modification of both the screw’s rotational kinematics and its local geometry. The integration of a compact cycloidal drive directly within the screw shaft creates a controlled speed differential along the screw length. Simultaneously, a section with reversed flight direction is introduced to promote material reflux and re-circulation. This combined approach aims to disrupt streamlined flow, increase shear history, and prolong the residence time of the material within the mixing zones. The design process, analysis, and validation of this novel configuration form the basis of this comprehensive investigation.

Parametric Optimization and Geometric Model Design

The design process commenced with a systematic parametric optimization to define the core dimensions of the twin-screw assembly. Given the complexity of the system, a focused optimization on key geometric parameters influencing mixing and conveying was conducted using MATLAB’s Optimization Toolbox. The objective was to maximize mixing performance while adhering to the fundamental constraints of twin-screw geometry, such as proper intermeshing and mechanical strength. The governing equations for the screw geometry are central to this optimization.

The relationship between the screw’s outer diameter, root diameter, and channel depth is fundamental:

$$ D_s – 2H = D_b $$

where $D_s$ is the screw outer diameter, $D_b$ is the screw root diameter, and $H$ is the channel depth. The lead and helix angles are determined by:

$$ \tan(\psi_s) = \frac{T}{\pi D_s}, \quad \tan(\psi_b) = \frac{T}{\pi D_b} $$

Here, $T$ is the screw lead, and $\psi_s$ and $\psi_b$ are the helix angles at the screw tip and root, respectively. The lead is related to the pitch $S$ and the number of flights $n$ by:

$$ T = n \cdot S $$

For proper meshing of two identical, co-rotating screws, the centerline distance $CL$ must satisfy:

$$ CL = \frac{D_s + D_b}{2} \quad \text{and} \quad CL < D_s $$

The flank angle $\alpha$ can be derived from:

$$ \cos\left(\frac{\alpha}{2}\right) = \frac{CL}{D_s} $$

Applying these equations within the optimization framework, with constraints including a length-to-diameter ratio between 4 and 6, a double-flighted design ($n=2$), and a relatively large lead to aid conveyance, yielded the primary design parameters summarized in the table below.

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Total Screw Length | $L$ | 390 | mm |

| Forward Flight Section Length | $L_1$, $L_3$ | 150 (each) | mm |

| Reverse Flight (Variable Speed) Section Length | $L_2$ | 90 | mm |

| Screw Outer Diameter | $D_s$ | 100 | mm |

| Screw Root Diameter | $D_b$ | 80 | mm |

| Screw Pitch | $S$ | 30 | mm |

| Centerline Distance | $CL$ | 96 | mm |

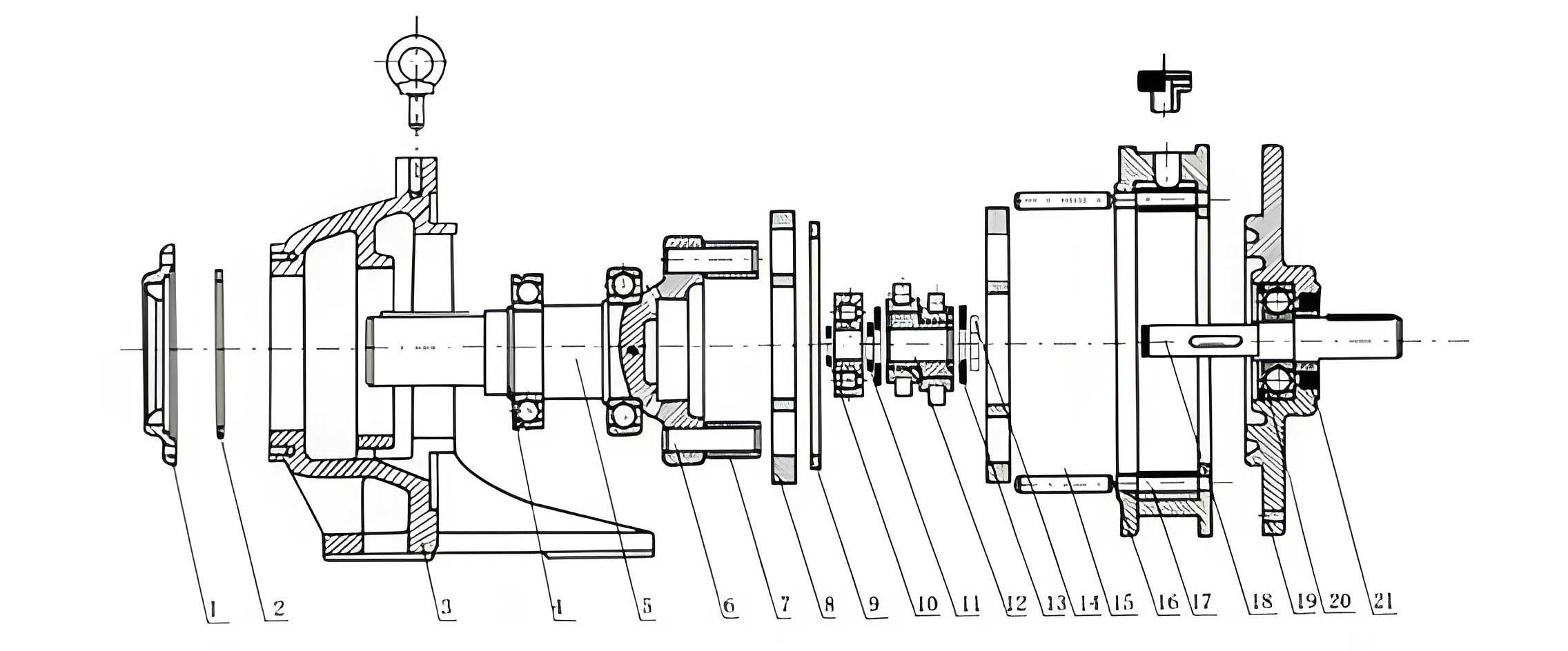

Based on these parameters, a three-dimensional geometric model was constructed. The screw assembly was divided into three distinct functional zones: two standard conveying sections at the inlet and outlet, and a central “variable-speed” section housing the novel elements. This central section incorporates the reverse-flight geometry and internally houses the cycloidal drive reduction unit.

The cycloidal drive was specifically designed to fit within the root diameter of the screw. The selected configuration featured a cycloid disc with 7 lobes meshing with 8 stationary pin gears. This provides a high reduction ratio in a compact form factor. The speed reduction ratio $i$ for such a cycloidal drive is given by:

$$ i = \frac{N_p}{N_p – N_c} $$

where $N_p$ is the number of pins (8) and $N_c$ is the number of lobes on the cycloid disc (7). Thus, the theoretical reduction ratio is:

$$ i = \frac{8}{8-7} = 8:1 $$

In the practical assembly, the input shaft of the cycloidal drive is connected to the forward section of the screw, and the output shaft is connected to the reverse-flight section. This setup ensures that the central section rotates at a significantly lower speed than the inlet and outlet sections when the main drive shaft rotates at a constant speed.

Mathematical Model and Simulation Setup for Flow Field Analysis

To analyze the mixing performance, a computational fluid dynamics (CFD) approach was employed. The non-Newtonian, viscous flow of soybean meal within the extruder barrel was simulated. Key assumptions were made to formulate a tractable mathematical model: the flow was assumed to be isothermal, steady-state, laminar, and fully developed within the screw channels. The soybean meal was modeled as an incompressible power-law fluid, with wall adhesion (no-slip condition) at both the screw and barrel surfaces.

The governing equations for the flow are the continuity equation and the Cauchy momentum equations. For an incompressible flow, the continuity equation simplifies to:

$$ \nabla \cdot \vec{V} = \frac{\partial V_x}{\partial x} + \frac{\partial V_y}{\partial y} + \frac{\partial V_z}{\partial z} = 0 $$

The momentum conservation equations, neglecting body forces, are:

$$ \rho \left( \frac{\partial \vec{V}}{\partial t} + \vec{V} \cdot \nabla \vec{V} \right) = -\nabla p + \nabla \cdot \boldsymbol{\tau} $$

For steady-state flow, the time derivative term vanishes. The stress tensor $\boldsymbol{\tau}$ for a generalized Newtonian fluid is related to the strain rate tensor $\dot{\boldsymbol{\gamma}}$ by the constitutive equation. For the power-law model:

$$ \boldsymbol{\tau} = \mu(\dot{\gamma}) \dot{\boldsymbol{\gamma}}, \quad \text{where} \quad \mu(\dot{\gamma}) = K \dot{\gamma}^{\, n-1} $$

Here, $\dot{\gamma}$ is the shear rate magnitude, $K$ is the consistency index, and $n$ is the power-law index. For shear-thinning (pseudoplastic) materials like soybean meal, $n < 1$.

The boundary conditions for the simulation were defined based on the operational parameters of a standard extruder and the novel design’s kinematics:

| Boundary/Parameter | Setting |

|---|---|

| Inlet Sections (Forward Flight) | Rotational Speed: 120 rpm |

| Central Section (Reverse Flight with Cycloidal Drive) | Rotational Speed: 120 rpm / $i$ ≈ 17.1 rpm |

| Material Inlet | Velocity Inlet: 0.05 m/s |

| Flow Outlet | Pressure Outlet: 1 MPa |

| Barrel Wall | Stationary, No-Slip |

| Screw Surfaces | Rotating with specified zone speeds, No-Slip |

| Material Properties (Soybean Meal) | Density: 700 kg/m³; Apparent Viscosity Model: Power-law parameters fitted to 1930 Pa·s at a reference shear rate. |

The three-dimensional fluid domain was created, and a high-quality tetrahedral mesh was generated for the complex intermeshing region. The ANSYS CFX solver was used to simulate the pressure and velocity fields for both a conventional twin-screw design and the novel cycloidal drive-enhanced design.

Analysis of Flow Field and Mixing Performance

Macroscopic Pressure Field Comparison

The simulated pressure field provides crucial insight into the conveying and mixing behavior. In the conventional twin-screw design, the pressure increased monotonically and smoothly from the inlet to the outlet. This indicates stable, predictable pumping with minimal flow disruption. In contrast, the novel design exhibited a distinctly different pressure profile. While the overall trend was increasing, a significant pressure drop was observed within the central variable-speed section. This localized decrease in pressure is a clear indicator of flow disruption and the presence of a reflux zone. The reverse-flight geometry, combined with the speed differential created by the cycloidal drive, actively works against the forward conveying action, creating a region of re-circulation and re-mixing. The pressure must then rebuild in the final forward-flight section, confirming that material is held longer and worked more intensively in the central mixing zone.

Velocity Field and Shear Analysis

The velocity field analysis offers direct evidence of the enhanced mixing mechanism. Velocity vector plots for the conventional screw showed uniform, high-velocity flow aligned with the conveying direction. For the novel design, the vectors within the central section showed a marked reduction in magnitude and increased directional complexity, with clear components opposing the main flow.

Quantitative data extracted along the axial centerline of the flow domain starkly illustrates this effect. The following comparative plot (conceptual data derived from simulation results) shows the axial velocity component:

(Note: The plot below is a textual description of the data trend. In a full implementation, this would be an embedded chart or a data table.)

- Conventional Screw: Axial velocity remains relatively high and constant, with minor fluctuations corresponding to screw flight passing.

- Novel Screw with Cycloidal Drive: Axial velocity shows a pronounced decrease in the zone corresponding to the central section (approximately 0.15m to 0.24m along the axis). The velocity here is significantly lower than in the inlet/outlet sections, confirming the effective speed reduction from the integrated cycloidal drive.

Furthermore, an analysis of velocity streamlines on cross-sectional planes reveals the mixing quality. In a standard conveying section, streamlines are smooth and orderly. In the variable-speed section with the reverse flight, the streamlines become chaotic, broken, and form localized vortices. The presence of these vortices and the breakdown of laminar flow layers are direct visual proof of distributive mixing enhancement. The repeated shearing action within these vortices contributes to dispersive mixing.

Experimental Validation and Residence Time Distribution

To validate the computational findings, a practical experiment was conducted using a laboratory-scale twin-screw extruder. Soybean meal was processed at several screw speeds, and the mean residence time was measured for both a standard screw configuration and the novel design featuring the cycloidal drive and reverse flight. The results unequivocally demonstrated the extended processing time afforded by the new design.

| Screw Speed (rpm) | Conventional Screw Residence Time (s) | Novel Screw Residence Time (s) | Increase in Residence Time |

|---|---|---|---|

| 80 | 30.42 | 36.54 | ~20.1% |

| 100 | 24.95 | 29.96 | ~20.1% |

| 120 | 20.02 | 24.05 | ~20.1% |

| 140 | 16.54 | 19.82 | ~19.8% |

| 160 | 14.85 | 17.81 | ~19.9% |

The data shows a consistent increase in residence time of approximately 20% across all tested speeds for the novel design. This extended exposure to shear and thermal energy within the barrel directly translates to more thorough mixing, cooking, and homogenization of the feed material, confirming the primary objective of the design.

Optimization of the Cycloidal Drive Placement

An ancillary investigation was performed to determine the optimal axial placement of the cycloidal drive unit within the screw assembly. Three configurations were analyzed via simulation:

- Base Novel Design: Cycloidal drive located in the central section.

- Optimization Variant 1: Cycloidal drive located in the inlet section.

- Optimization Variant 2: Cycloidal drive located in the outlet section.

The evaluation criteria were the pressure build-up capability and the velocity profile. The analysis yielded clear results:

- Pressure Build-up: Variant 2 (drive at outlet) showed the highest final pressure, but this was achieved with less intermediate mixing disruption.

- Velocity Profile & Mixing: Both Variant 1 and 2 failed to create the pronounced, localized velocity minimum and flow reversal in a dedicated mixing zone. The speed change occurred too early or too late in the transport process, reducing its effectiveness for creating a controlled reflux region.

- Optimal Configuration: The base novel design, with the cycloidal drive and reverse flight co-located in a dedicated central section, provided the best compromise. It generated a distinct low-speed, high-shear mixing zone flanked by efficient conveying sections, leading to the most effective overall combination of pumping stability and mixing intensity.

This optimization step underscores the importance of synergizing the kinematic change from the cycloidal drive with a complementary geometric feature (the reverse flight) in a strategically placed zone.

Conclusion

This study successfully designed, analyzed, and validated a novel twin-screw configuration that significantly enhances mixing performance. The integration of a compact cycloidal drive reduction unit within the screw shaft, coupled with a reverse-flight element, introduces a controlled kinematic and geometric discontinuity. Computational Fluid Dynamics (CFD) simulations revealed that this design successfully creates a defined zone of material reflux, reduced axial velocity, and complex vortex generation, all indicators of intensified distributive and dispersive mixing. Experimental trials confirmed a substantial increase of approximately 20% in material residence time, directly correlating to improved mixing efficacy. Furthermore, optimization studies confirmed that positioning the cycloidal drive within a dedicated central mixing section, rather than at the inlet or outlet, yields the most favorable flow dynamics for overall process performance. This work demonstrates a potent and mechanically innovative approach to overcoming the mixing limitations of conventional twin-screw extruders, with significant potential applications in feed, food, and polymer processing industries where homogenization is critical. The principle of using an integrated cycloidal drive for localized speed control opens new avenues for active, zoned management of extrusion processes.