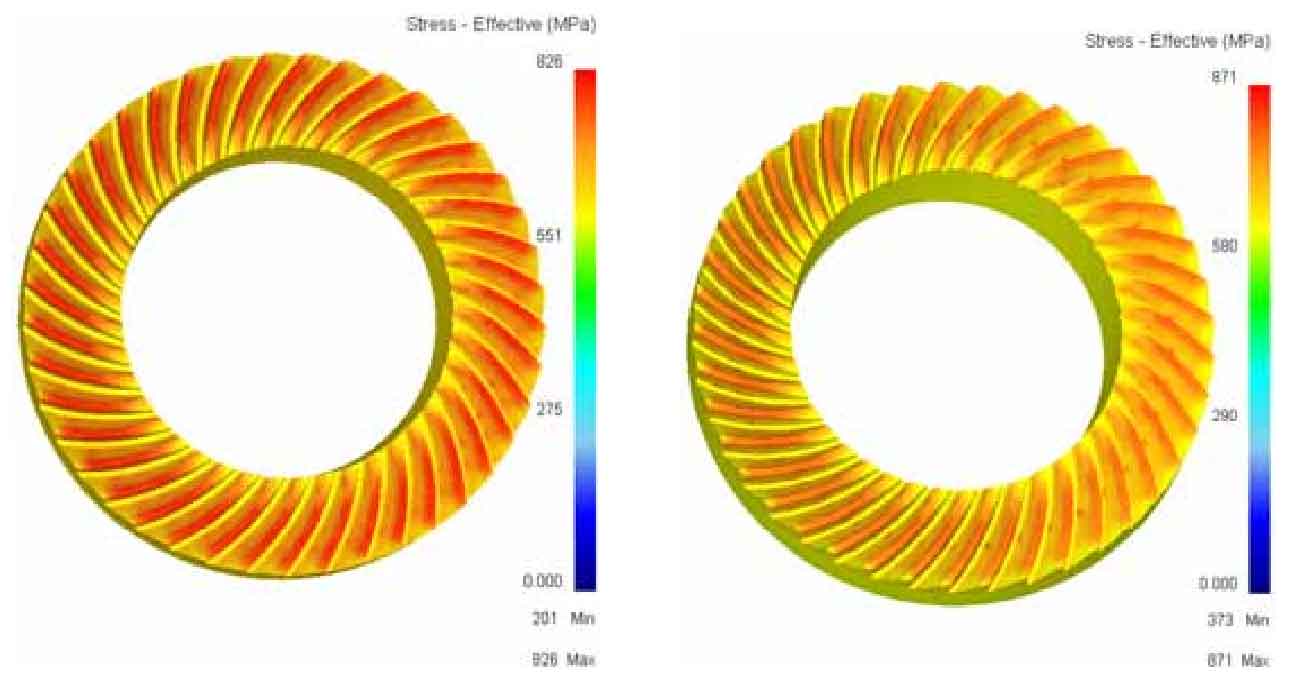

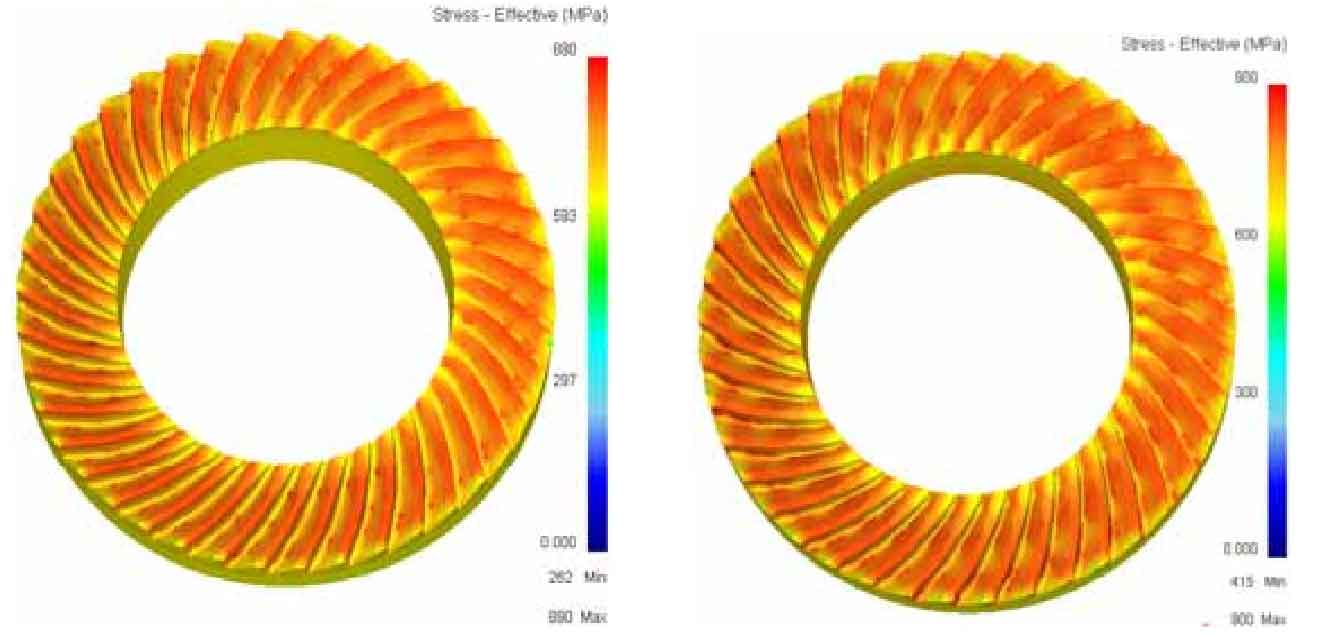

As shown in the figure, the equivalent stress distribution diagram corresponding to different finishing quantities at the end of cold finishing of bevel gear profile blank. As can be seen from the figure: λ When equal to 0.15mm, the maximum equivalent stress value is 826mpa, the equivalent stress value at the crown of bevel gear is about 795mpa, the equivalent stress value at the tooth surface of bevel gear is about 710MPa, and the equivalent stress value at the tooth root is about 665mpa. λ When equal to 0.3mm, the maximum equivalent stress value is 871mpa, the equivalent stress value at the crown of bevel gear is about 800MPa, the equivalent stress value at the tooth surface of bevel gear is about 725MPa, and the equivalent stress value at the tooth root of bevel gear is about 692mpa. Compared with equal to 0.15mm, the equivalent stress value of each part is increased, and the maximum equivalent stress value is increased.

λ When it is equal to 0.45mm, the maximum equivalent stress value is 890mpa, the equivalent stress value at the crown of bevel gear is about 824mpa, the equivalent stress value at the tooth surface of bevel gear is about 775mpa, and the equivalent stress value at the root of bevel gear is about 718mpa. And λ Equal to 0.3mm, the equivalent stress value of each part is increased, and the maximum equivalent stress value is increased.

λ When equal to 0.6mm, the maximum equivalent stress value is 900MPa, the equivalent stress value at the crown of bevel gear is about 843mpa, the equivalent stress value at the tooth surface of bevel gear is about 815mpa, and the equivalent stress value at the tooth root of bevel gear is about 752mpa. And λ Equal to 0.45mm, the equivalent stress value of each part is increased, and the maximum equivalent stress value is increased.

According to the above summary, λ When the values are different, the larger value of the equivalent force is mainly distributed on the tooth surface and tooth top of the bevel gear tooth profile, and the equivalent stress value at the tooth top of the bevel gear is greater than that at the tooth surface of the bevel gear. Therefore, it can be concluded that the metal material at the tooth top of the bevel gear flows more violently than that at other parts. With the gradual reduction of the finishing amount, the equivalent force value also decreases, and the distribution area decreases. Therefore, it can be explained that with the reduction of the finishing amount, the material flow becomes more and more stable, and the value of the finishing amount mainly depends on the quality of the hot forging blank.