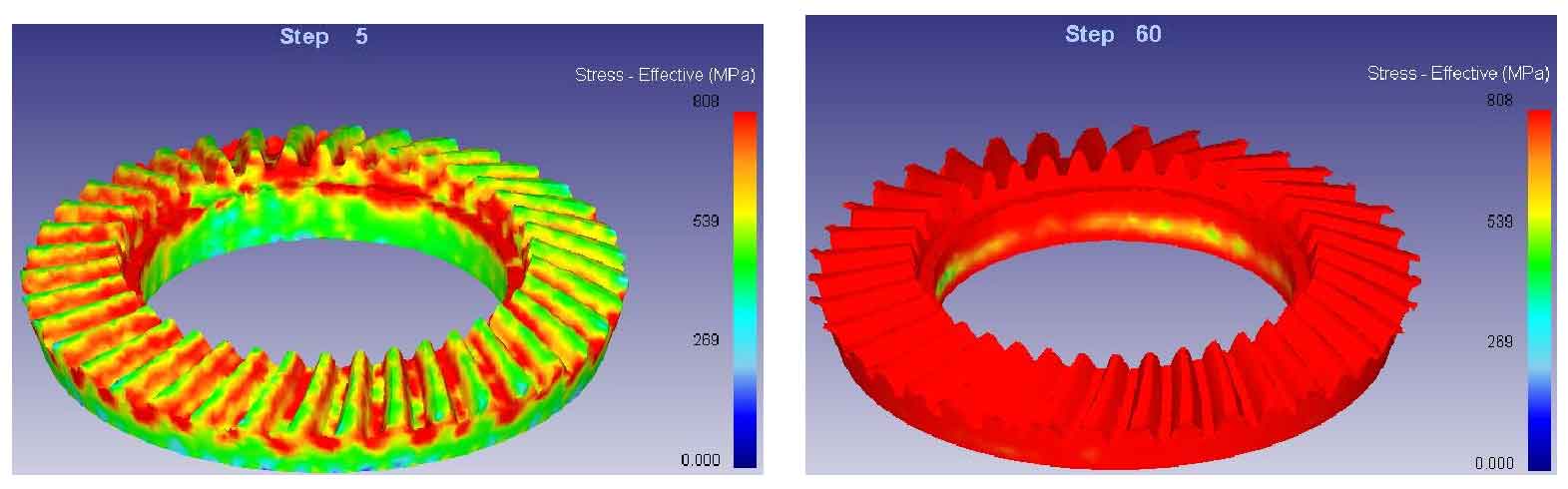

The figure shows the equivalent stress distribution diagram of spiral bevel gear at different strokes in the cold finishing process, figure (a) shows the equivalent stress distribution diagram when the stroke is 4 mm, and figure (b) shows the equivalent stress distribution diagram of the final step. From the change of the equivalent stress distribution in the cold finishing process of spiral bevel gear, it can be seen that when the upper die starts to move downward, the places with large equivalent stress are mainly concentrated in the tooth shape of the gear. When the stroke exceeds 4 mm, The equivalent stress of each part increases rapidly, and the equivalent stress distribution of each part is relatively uniform and the difference is small. The maximum equivalent stress is 808 MPa, which is about 2.7 times that of warm precision forging.

In the warm precision forging process of spiral bevel gear, the forming temperature is high, the metal plasticity is high, and the equivalent stress in the forming process is relatively low; The cold finishing temperature of spiral bevel gear is low, the metal plasticity is relatively low, and the equivalent stress in the forming process is relatively large.