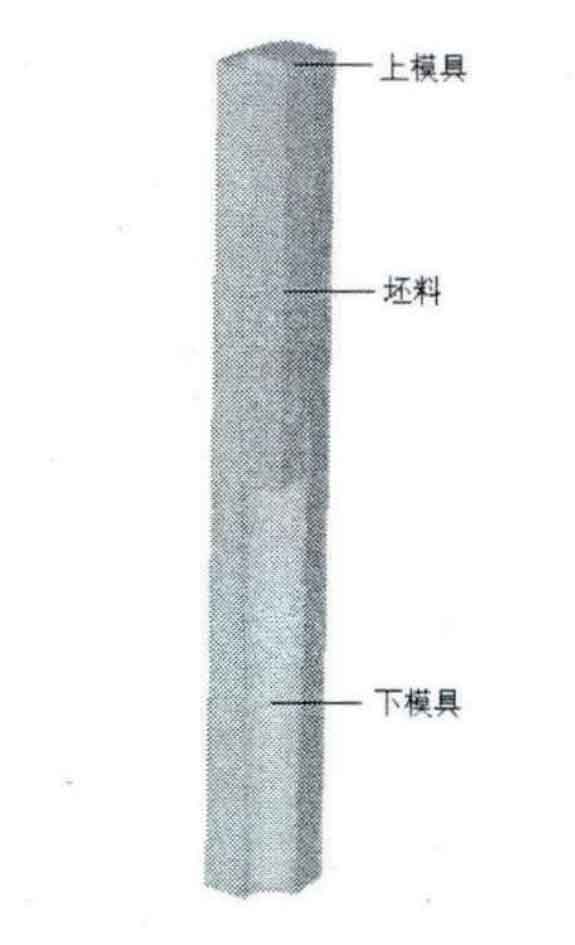

Using Pro / E4 0 establish the geometric model of extrusion process, including the geometric model of upper and lower dies and the geometric model of blank. According to the drawings provided by the enterprise, the blank is φ 40mmx196mm bar material. Because the upper and lower dies and blanks are symmetrical, only 1 / 4 model is taken for research, and the established assembly drawing is shown in Figure 1.

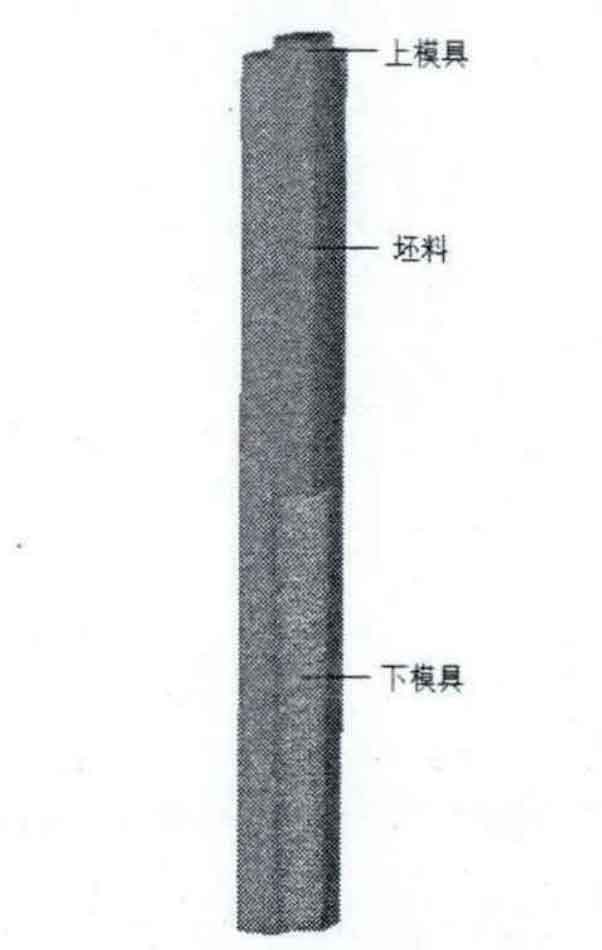

The geometric model is imported into the preprocessor in format to establish the finite element model.

(1) Meshing

Divide the grid according to the introduction. After division, the grid number of the upper die is 8135, the grid number of the blank is 109021, and the grid number of the lower die is 110174.

(2) Basic attribute setting of blank and upper and lower dies

The blank is set as a plastic body, the initial forging temperature is 1050 ° C, and the material is 20CrMnTiH. Set the upper and lower molds as rigid bodies, the initial temperature is 250 ° C, and the material is 4Cr5MoSiV1.

(3) Analog control parameter setting

Set the iteration method as 28mm, set the iteration method as 28mm, and use the gradient simulation method as 28mm.

(4) The friction coefficient is 0.3, and the downward speed of the upper die is 5mm / s.

The final finite element model is shown in Figure 2.