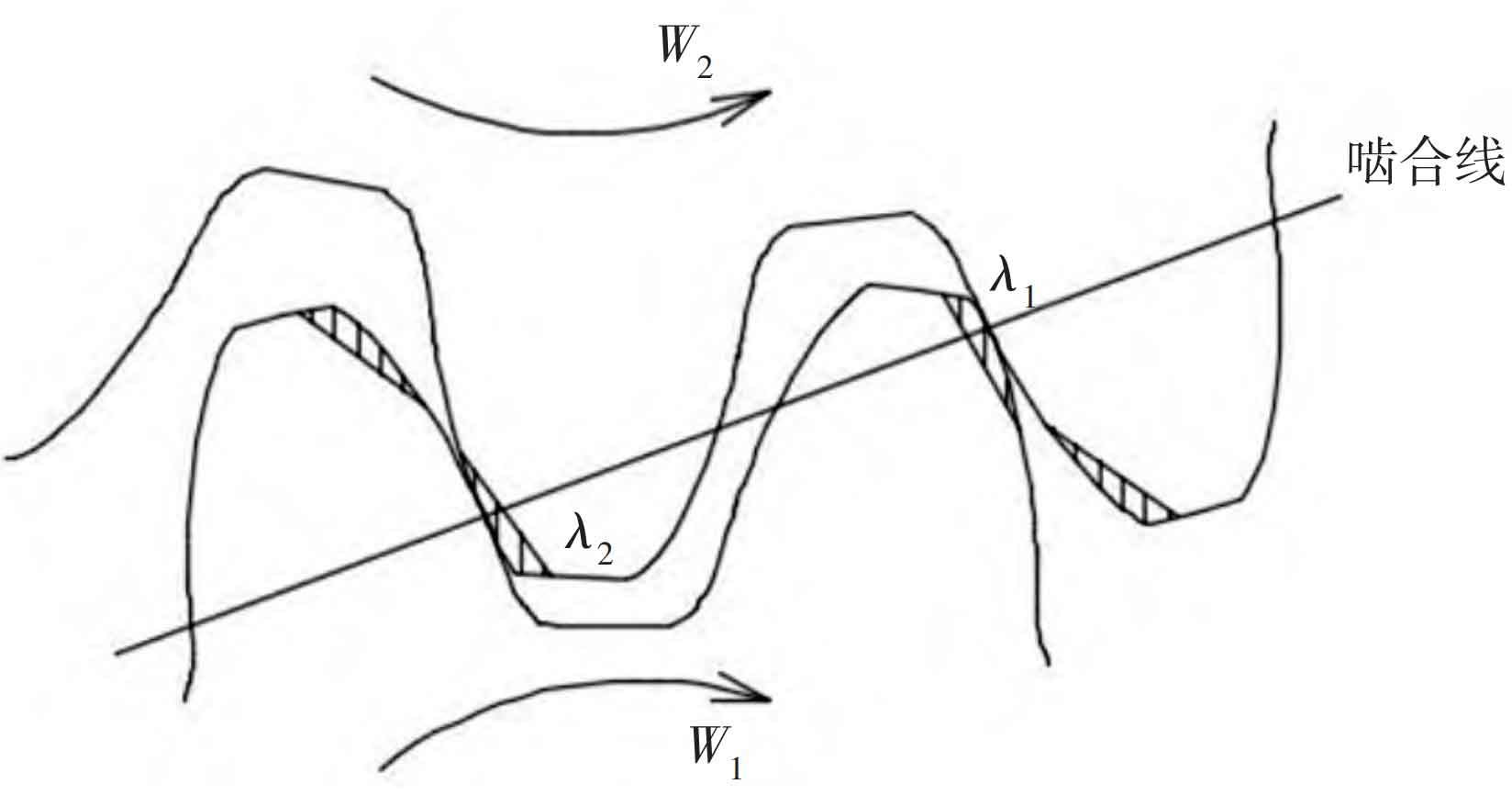

When the spur gear teeth enter the double-tooth meshing area, the two pairs of teeth theoretically contact at the same time, but if the amount of trimming is not properly distributed or the amount of trimming is too large, the front pair of teeth in the position shown in the figure does not actually contact, resulting in the reduction of the length of the meshing line, that is, the actual coincidence is reduced, as shown in Figure 1. Define the actual base pitch of the driving and driven gears as pb1 and pb2 respectively, and the trimming amount of the front and rear pair of teeth is respectively λ 1、 λ 2. The normal deformation of the driving and driven gears after being loaded at the meshing (meshing) stage is: Δ pb1 ( Δ′ Pb1) and Δ pb2 ( Δ′ pb2 )。

From the deformation compatibility relationship, when the inequality is satisfied: pb2+ Δ pb2 – λ 2 > pb1 + Δ pb1 – λ At 1 o’clock, the front pair of teeth is in a non-contact state, and the spur gear pair will exit the double-tooth meshing in advance; When the inequality is satisfied: pb1+ Δ′ pb1 – λ 1 > pb2 + Δ′ pb2 – λ At 2, it will delay entering the double-tooth meshing stage. Therefore, when the amount of trimming is greater than the meshing shape variable, the meshing area of double teeth will be reduced and the actual coincidence will be reduced.

The contact condition of each point can be deduced by the above method, and then the actual coincidence degree of spur gear can be calculated.

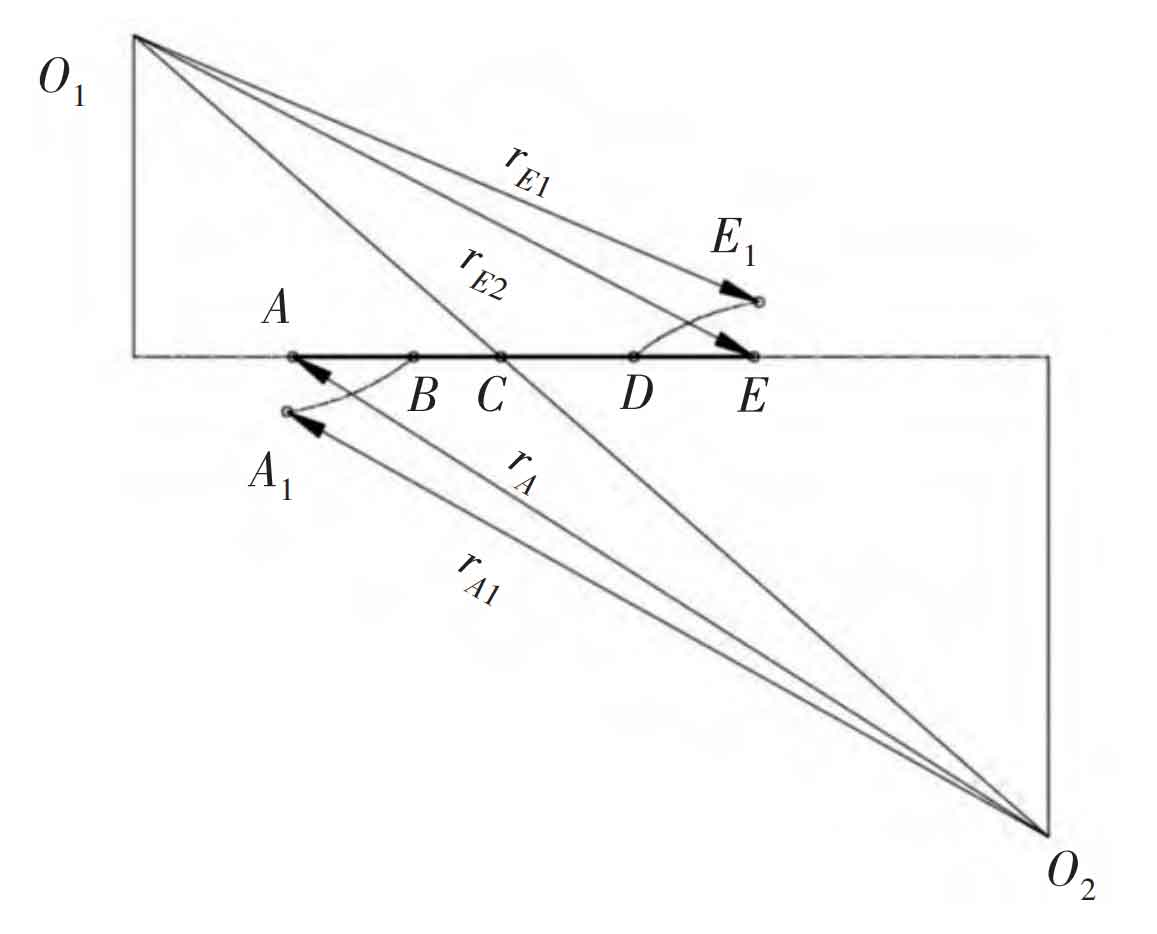

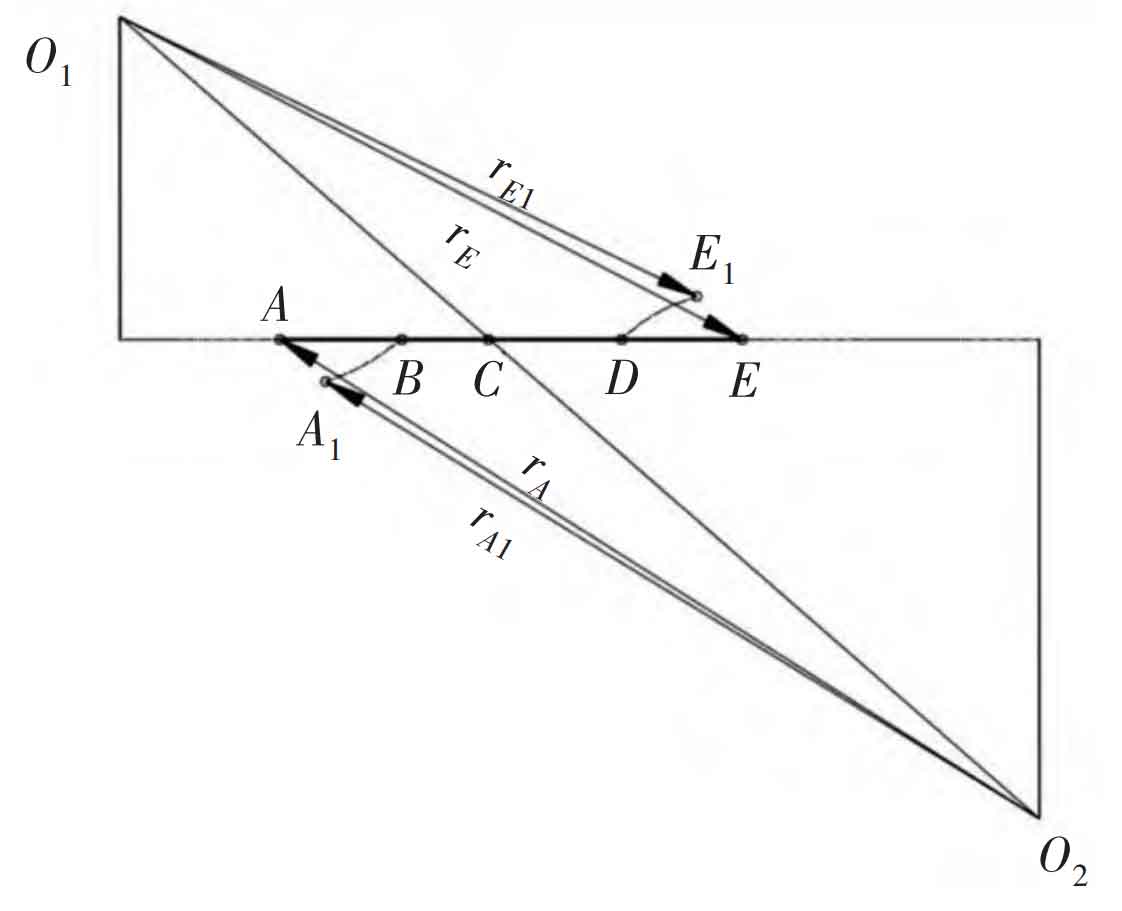

Amount of trimming in progress δ After determination, the shape variables are different under different working conditions, and the included angle of the meshing line ω The actual meshing radius r ′ x at the meshing point is different from each other, so the actual meshing line distribution under different working conditions is different. The actual meshing line distribution under continuous working conditions and high-speed working conditions is shown in Figure 2 and Figure 3.

Fig. 2 The actual meshing line track under continuous working condition is A1BDE1. The meshing line of the spur gear double-tooth meshing area deviates from the theoretical meshing line and its length is larger than the theoretical meshing line, so the actual coincidence ratio increases.

Fig. 3 The actual meshing line track under high-speed working condition is A1BDE1. The meshing line of the spur gear in the double-tooth meshing area deviates from the theoretical meshing line and its length is smaller than the theoretical meshing line, so the actual coincidence is reduced.