The basic parameters of the selected straight tooth surface gear are a straight tooth surface gear with a module of 1.35mm and a tooth number of 42. The number of teeth of the cutter is 17, and the specific basic parameters are shown in the table.

| Project | Spur gear | Tool |

| Modulus/(mm) | 1.35 | 1.35 |

| Helical angle/(°) | 0 | 0 |

| Pressure angle/(°) | 20 | 20 |

| Number of teeth | 42 | 17 |

| Tooth width/(mm) | 4.4 | 6 |

| Coefficient of displacement | 0 | 0 |

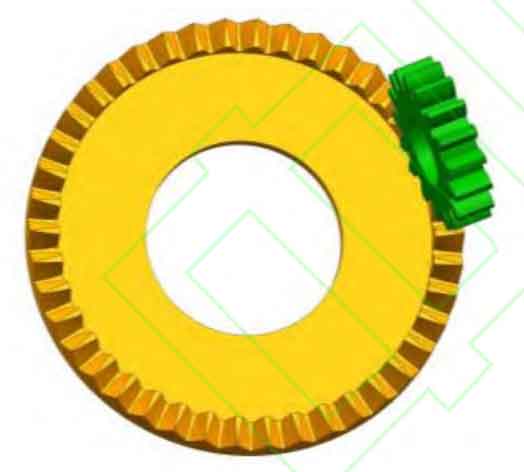

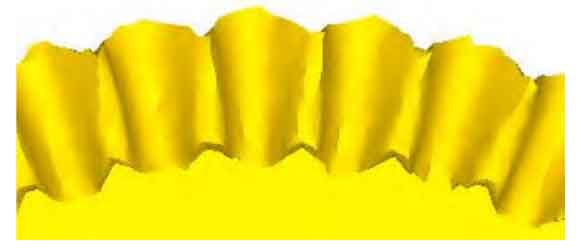

Calculate the tooth surface points of the straight tooth surface gear and its meshing cylindrical gear by writing a matlab program, and import the calculated “dat” file into the 3D software UG for modeling, as shown in Figure 1 and Figure 2.

Establish a three-dimensional model of the spur gear and mold wheel, obtain the tooth volume of the spur gear through the volume measurement function of UG software, and obtain the relevant dimensions of the wheel blank based on the equal volume method.

First, the volume of the effective teeth is obtained. Since the effective blank portion of the spur gear is a hollow cylinder, the volume of the blank can be calculated by simply calculating the volume A1=A2 based on the unchanged volume of the spur gear before and after rolling. The three-dimensional model of the blank is shown in Figure 3.

The assembly diagram of tool wheel and wheel blank during hot rolling of spur gear is shown in Figure 4. Gear rolling is a gear that cooperates with a straight tooth surface gear. During the feeding process, the rolling wheel rotates while feeding, overcoming material deformation forces, and causing plastic deformation of the blank. As the feed rate continues to increase, the blank begins to perform a fanning motion with the rolling wheel, and finally the target gear is rolled out, as shown in Figure 5.

Therefore, the simulation of spur gear rolling is that the cylindrical gear needs to be fed along the axial direction of the spur gear while rotating. As the feed rate gradually increases, the spur gear wheel blank undergoes plastic deformation under the compression of the cylindrical gear, and the convex part undergoes a rotational motion with the teeth of the cylindrical gear to produce the tooth shape of the face gear.