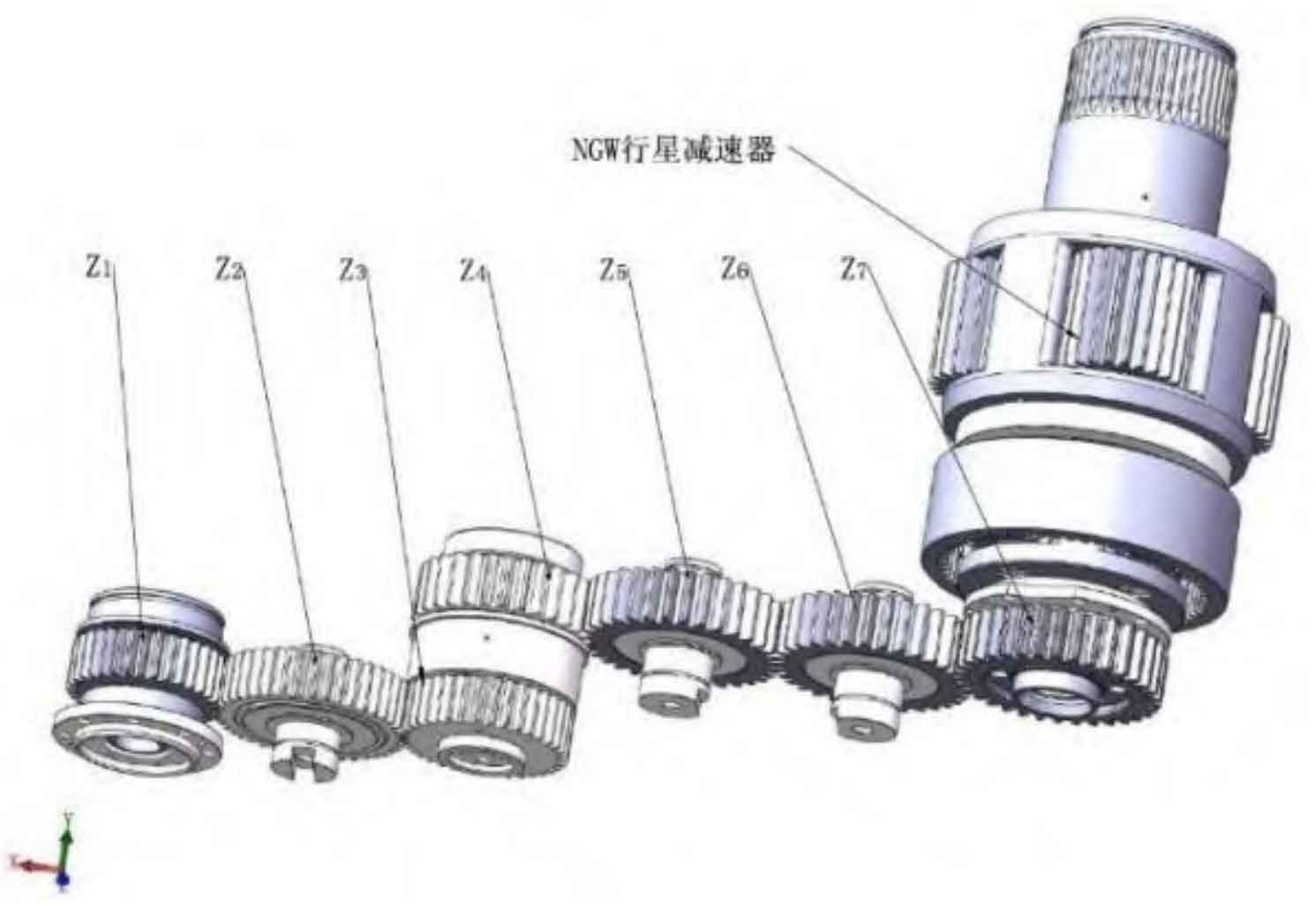

The working principle of rocker arm gear drive of a thin seam shearer is shown in Figure 1. The gears Z2, Z5 and Z6 are idler gears, and the rest are meshing gears. NGW planetary reducer is connected with the end spur gear Z7 through splines, which plays an important role in transmitting large power, bearing complex loads, and transferring power to the drum through deceleration.

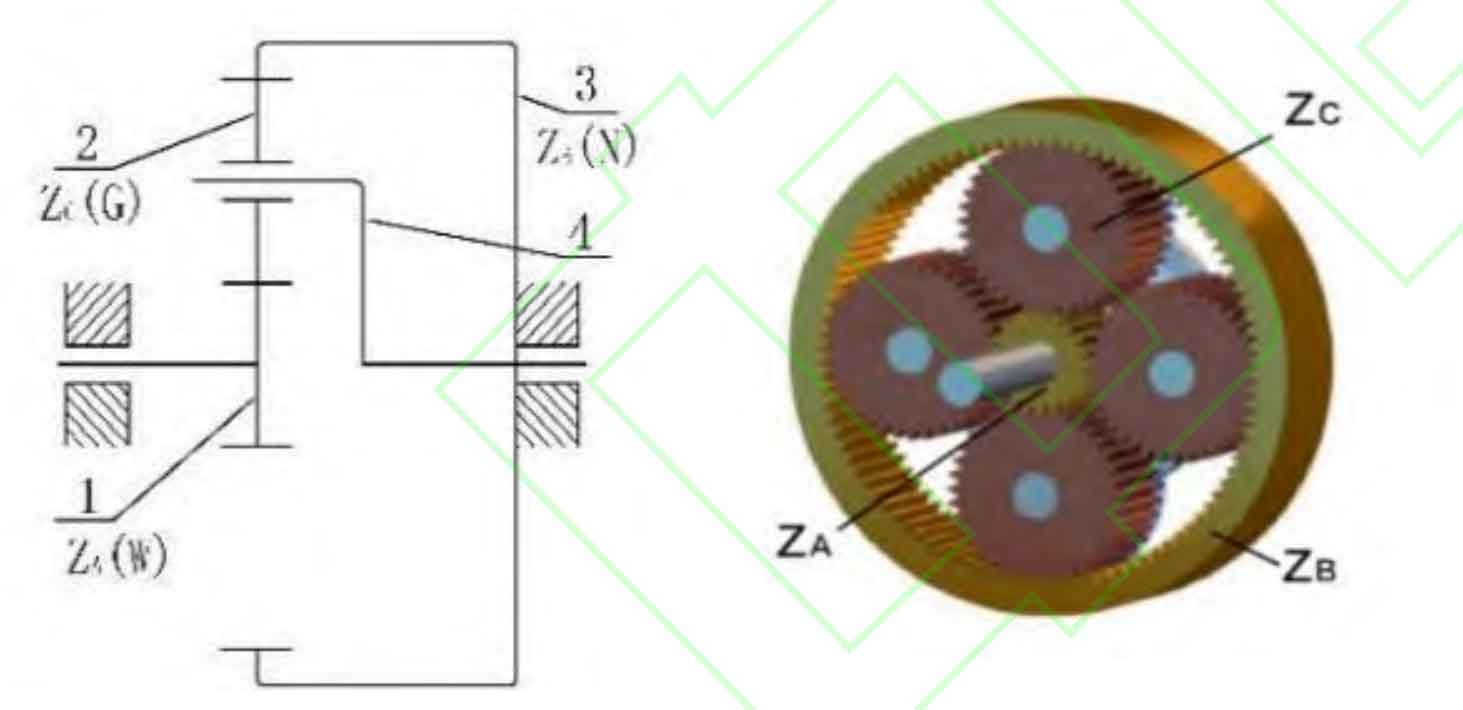

The NGW type planetary transmission gear is a four planet gear reduction mechanism, which is mainly composed of sun gear, planet gear, internal gear ring, planet carrier, etc. Its transmission structure is shown in Figure 2, and the basic parameters of traditional empirical design are shown in Table 1, with the following characteristics:

1) To ensure good coal loading effect, control the radial size; At the same time, the force of the reduction system is balanced, and the sun gear is automatically centered. It is planned to use 4 planetary gears for meshing.

2) In order to meet the load sharing characteristics of the four planetary gears, the sun gear adopts a floating structure; It can float sensitively along the axial direction, reduce the reverse torque, and ensure the axial floating amount through the external spline side clearance matched with the big gear.

3) When the sun gear rotates under force, it drives the planet gear to rotate along each axis and drives the planet carrier to rotate; The planet carrier is connected with the square sleeve through splines to transmit the output torque to the roller.

When the drum shearer is cutting coal and rock, the planetary reducer bears complex impact load. The number of teeth of the sun gear is small, the diameter is small, the number of load cycles is the largest, and the planetary gear is subjected to internal and external bending loads. The sun gear and planet gear are made of high-quality alloy steel 18Cr2Ni4WA of the same material, which is subject to multi process treatment such as carburizing, quenching, gear grinding and shot peening to improve the contact and bending fatigue strength. The strength and hardness of the internal gear ring can be appropriately reduced. High strength steel 42CrMo is selected and deep nitriding treatment is carried out after gear shaping.