In actual processing, forging blanks are mostly formed by pre forging. First, the blank is pre forged into a blank with a size similar to that of large wheel forgings. Sometimes, the pre forging also carries out the rough forming of spiral bevel gears, and then through cold finishing to improve the precision of the final forging. It is a more reasonable process, which can not only improve the efficiency of forging, but also increase the service life of cold forging dies.

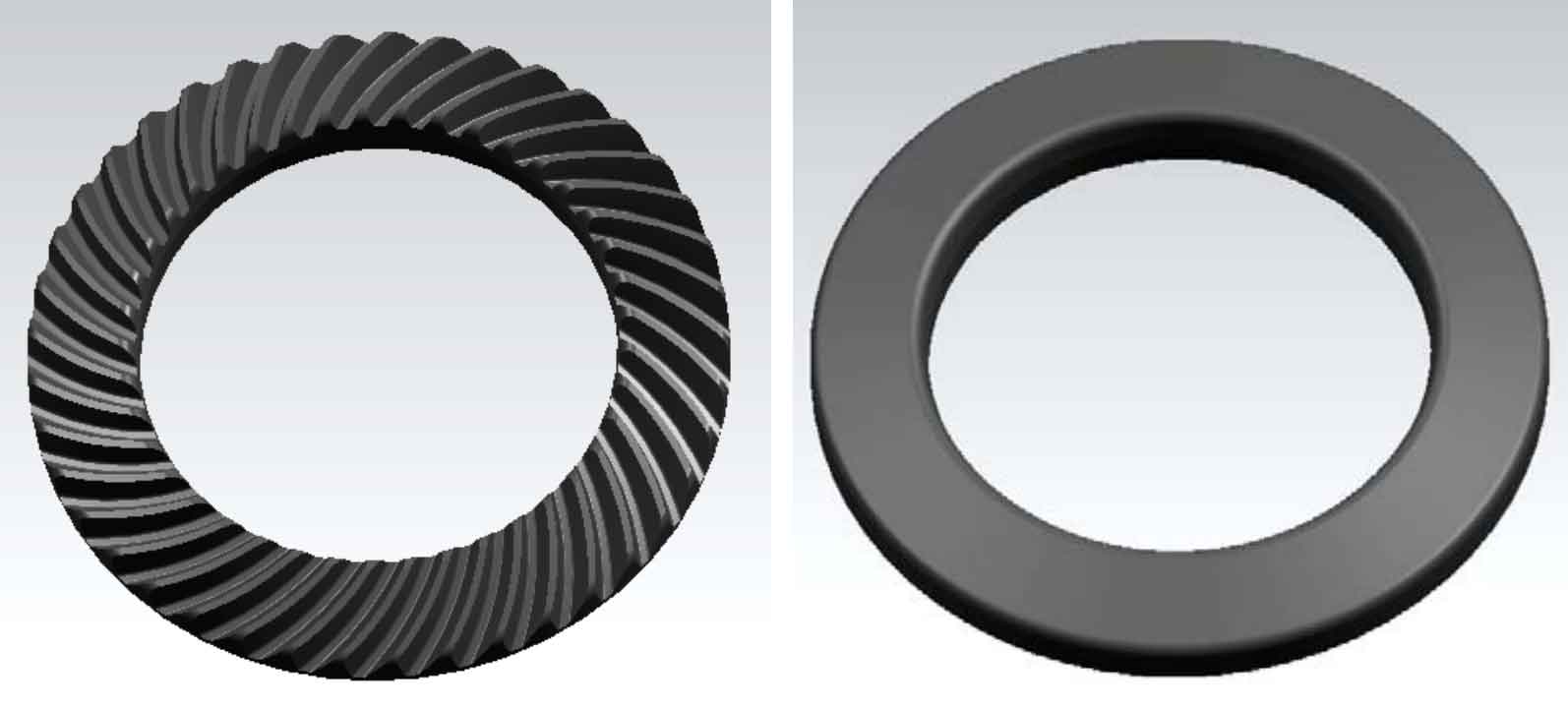

The blank model of cold precision forging spiral bevel gear is designed into a blank shape similar to the overall contour of spiral bevel gear, that is, it has the same cone angle. This design can improve the material forming accuracy during forging, reduce the amount of material flow and flash, and improve the product accuracy and the utilization rate of blank materials. The blank model designed according to the model of the big wheel is shown in the figure.

As shown in the figure, the model of cold precision forging spiral bevel gear blank is established according to the model of the big wheel, and the fillet treatment is carried out. This treatment can smoothly transition the included angle of the two surfaces and will not cause too much damage to the die during forging. The cold precision forging spiral bevel gear blank model is different from the big wheel only at the tooth slot. This design can reduce the deformation of the blank during forging, It can reduce the forging forming force, so as to reduce the tonnage of the required forging press.