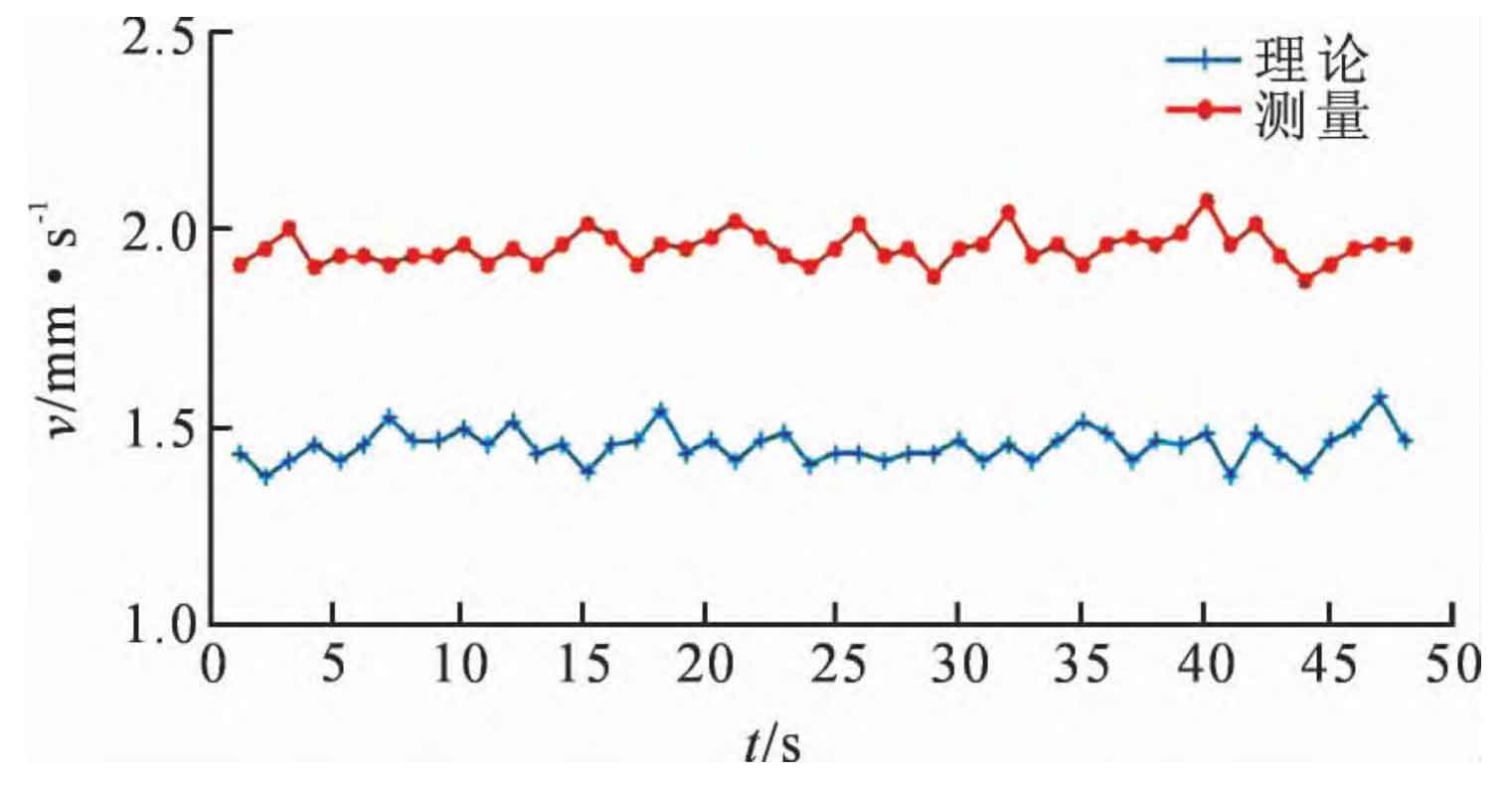

In order to evaluate the accuracy of the model, the measured results of herringbone gear at 1000r · min ^ – 1 are directly compared with the theoretical results. It can be seen from the figure that the overall shape of the response curve is in good agreement. Although a small number of errors can be seen, the reasonable consistency between the model and the experiment is still quite obvious.

1) A 12 degree of freedom bending torsion shaft dynamic analysis model of the transmission system considering the symmetry deviation of the teeth on both sides of the herringbone gear is established, and the time-varying meshing stiffness of the teeth engagement on both sides considering the influence of the symmetry deviation is accurately solved by using the finite element method. The results show that the symmetry deviation significantly reduces the comprehensive meshing stiffness of the herringbone gear pair.

2) Using herringbone gear pitch measurement method, the symmetry deviation of small wheel is 0.025 mm, and that of large wheel is 0.048 mm; The dynamic equation is solved by Runge Kutta method, and the axial vibration velocity of the transmission system under different working conditions is obtained; A closed power flow herringbone gear transmission test-bed was built, and the herringbone gear was tested in the actual torque and speed range. The test results showed that the increase of torque and speed would cause the increase of vibration speed; The direct comparison between the theoretical analysis results and the experimental results shows that the variation trend of the axial vibration velocity of the small wheel is highly consistent.

3) The theoretical analysis results obtained only take into account the dynamic behavior of herringbone gear system under different working conditions, so there is a large error compared with the experimental data of herringbone gear box surface. Considering the dynamic characteristics of herringbone gear box, it is a further study to establish the coupling dynamic analysis model of herringbone gear system and box and explore the coupling vibration of herringbone gear box.