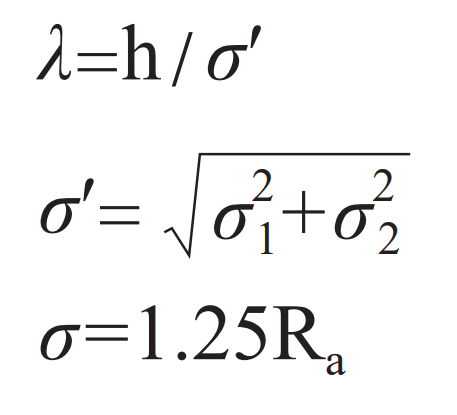

In practical applications, only knowing the thickness of the oil film can not accurately evaluate the lubrication state of the oil film when the spiral bevel gear is running, because the meshing of the spiral bevel gear is a periodic movement, and the lubricating oil film also has the characteristics of periodic change. The film thickness ratio is usually used to evaluate the lubrication state of a machine. Film thickness ratio λ Numerical value is oil film thickness h and comprehensive surface roughness σ′ Ratio of:

Where, σ 1, σ 2 is the root mean square deviation of the profile of the two contact surfaces. Profile root mean square deviation of surface roughness σ It has the following approximate conversion relationship with the arithmetic mean deviation Ra of the contour. The arithmetic mean deviation Ra of the profile has corresponding requirements in industry, and is assigned according to different process levels.

When λ> At 3, it belongs to full-film elastohydrodynamic lubrication, and the lubricating oil film can completely wrap the tooth surface without separation; When 1 < λ < At 3, it belongs to partial film elastohydrodynamic lubrication, and the lubricating oil film may have cavitation effect, which has high requirements on the lubrication state; When λ< At 1, it belongs to boundary film lubrication. The lubricating oil film may have boundary lubrication and damage the tooth surface.

According to the design parameters of the spiral bevel gear, the root mean square deviation of the profile of the surface roughness of the hobbing finish machining is 0.4~0.6 μ m. Therefore σ 1= σ 2=0.5 μ M for calculation. According to the definition of the film thickness ratio formula, the judgment equation for the evaluation of the oil film status is prepared to determine the oil film’s classification, and the classification parameters are expressed by sft.

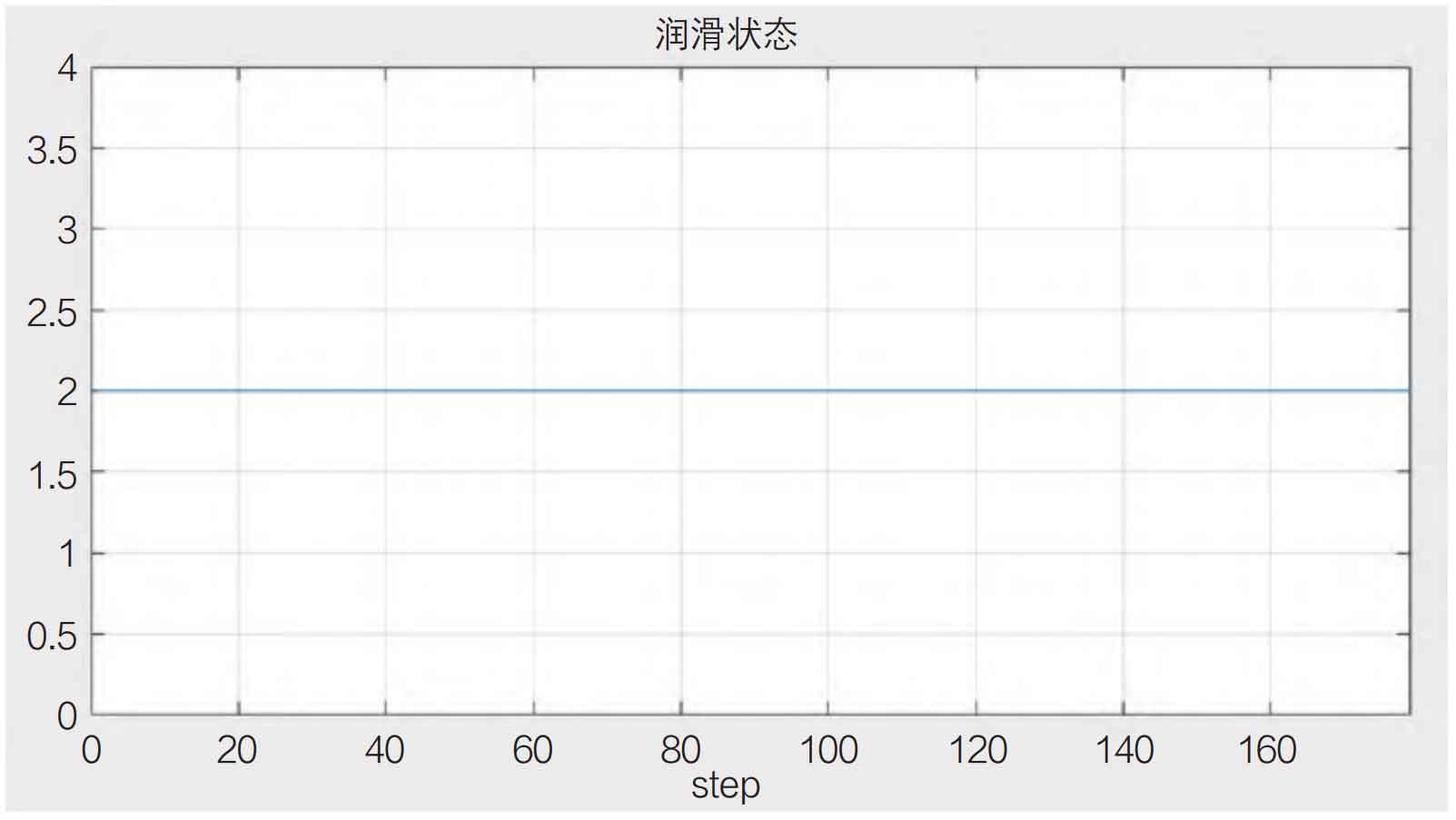

The calculation process is shown in Figure 8. The minimum oil film thickness value calculated above at the rated speed is brought into the judgment formula, that is, when the speed of the driving spiral bevel gear is 600 rpm, the image processing results are as follows.

According to the data, the spiral bevel gear is in partial film elastohydrodynamic lubrication during the meshing process at the assumed rated speed, and the film thickness ratio is found λ After that, it was found that the value was stable between [2.16, 2.91]. Although the film thickness ratio value was low, it was close to comprehensive lubrication in value. The oil film was in a relatively dangerous state, which was prone to cavitation effect and loss of lubricating oil film. It was necessary to put the spiral bevel gear set in an environment rich in lubricating oil.