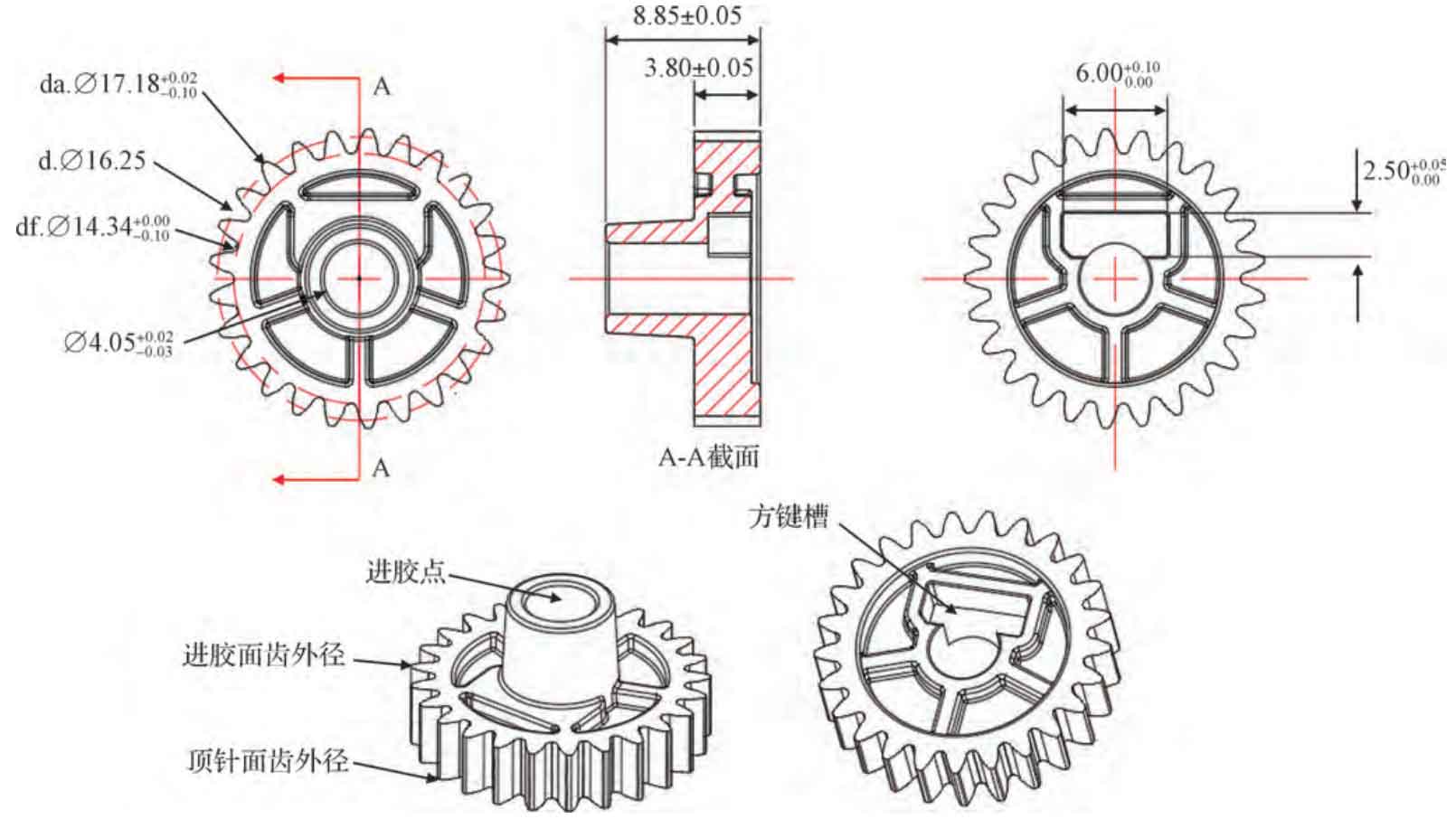

The experiment adopts the spur gear design shown in the figure. Because it needs to approach the working state of the actual gearbox, the spur gear with a step connecting shaft sleeve is used to facilitate the subsequent measurement of various dimensions. The general linear shrinkage factor (OSF)=1.165 is adopted for mold design, that is, all dimensions shown in the figure are enlarged by 1.165 times. The mold design and manufacturing work are carried out in the mold center inside the precision hardware company.

In order to confirm the distortion of spur gears after sintering, the MIM products shall be prepared after the mold is processed. The relevant steps are shown in Table. All equipment are mass production equipment to meet the evaluation of the actual manufacturing process. Each manufacturing procedure adjusts the optimization parameters more than 3 times to ensure that the experimental results meet the mass production standards.

| Step | Describe | Important parameters |

| Powder selection | Water-air combined atomization powder | D10>2.4 μ m,D50=7.9 μ m,D90<21 μ m |

| Feed manufacturing | Strong mixing | Conventional feeding process, shrinkage ratio 1.165 |

| Mold design | Three-plate mold | Common runner design |

| Injection molding | Electric injection machine (50 t) | Nozzle temperature 195 ° C |

| Pendulum row | Alumina ceramic bearing plate | Surface roughness Ra<10 μ m |

| Degrease | Oxalic acid catalytic degrease (400 L) | 120 ° C insulation for 5 h+front and rear washing |

| Sinter | Vacuum degreasing sintering (6 temperature zone/240 L) | High temperature argon partial pressure sintering+3 h insulation |

| Post-processing | Magnetic needle grinding | 60 r/min+30 min+forward and reverse+0.3 mm magnetic needle |

In order to obtain the best geometric shape after sintering, Moldflow analysis (Moldflow ®), The feeding rubber inlet of MIM stainless steel is located in the center of the shaft sleeve, which can obtain more uniform filling and improve the true roundness of the spur gear; At the same time, taking into account the thermal process after injection, the zonal pendulum test is adopted to observe the geometric shape and size of the final sintered product and obtain the best conditions; The manufacturing process of MIM uses oxalic acid degreasing furnace to fully degrease at 120 ° C for 6 hours, and confirms that the weight loss of green body degreasing is qualified (including weight method and crushing method), and then uses graphite thermal field vacuum degreasing sintering compound furnace with six-zone temperature control to sinter at 1 280~1 340 ° C, after obtaining the best sintering temperature, the test sample is copied.

For the straight gear sintered by MIM, the Archimedes principle is adopted for density measurement, and the microbalance is used to match the beaker and pure water for measurement. The sintered silver billet is soaked in vacuum to completely immerse the pure water into the open hole; Use Vicker’s hardness tester to test the hardness of the sample; The microstructure was observed by optical microscope after polishing and etching of metallographic photos, and compared with the microstructure of normal stainless steel 17-4P; The full-automatic spur gear measuring instrument of Japan Osaka Precision Machinery (TPR OSAKA SEIMITSU KIKAI CO, LTD. GC-1HP 1211) is used for dimension measurement, and the distortion degree between it and the design value is compared, and the drawing is used for description.

The experimental mold adopts a four-hole symmetrical three-plate mold. After the MIM gear products are sintered and ground, according to the above measurement results, the best process method is adopted, and with reference to our company’s experience in injection plastic spur gears, the deformation amount is reserved at the beginning of the mold design as compensation. During the pilot experiment, four mold cavities are designed, only two mold cavities are selected for wire cutting processing, and the normal shrinkage processing chart is used for the pilot experiment. According to the experimental results, the tooth shape of the compensation mold core is optimized. After the optimization experiment is verified, the full mold core is corrected to the final target size, and the final result is obtained by the full hole straight gear measurement after optimization.