1. Basic physical properties

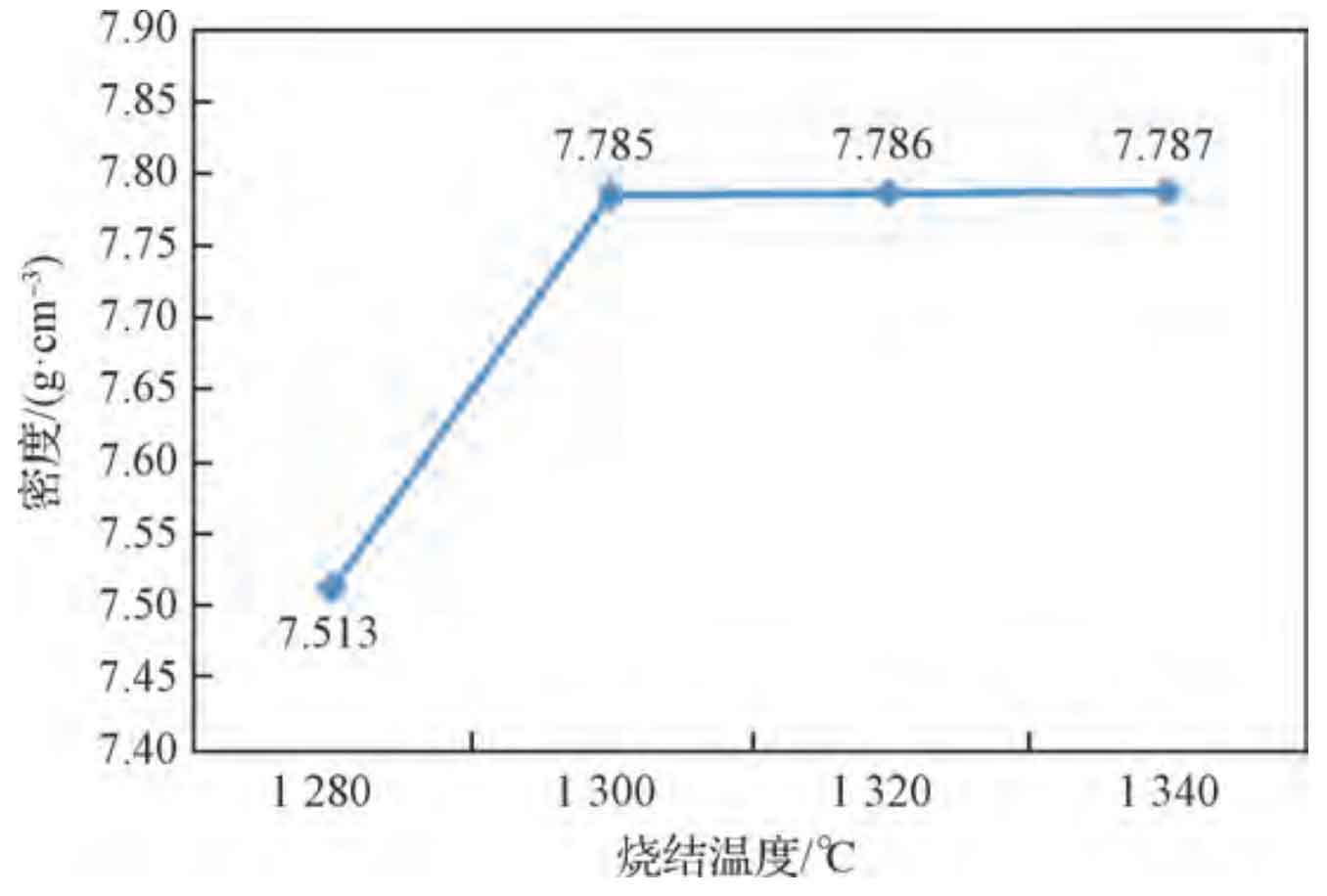

The density and hardness data of the product at 1 300 ° C for 3 h are shown in Figure 1 (four pilot and optimization experiments, five samples each time).

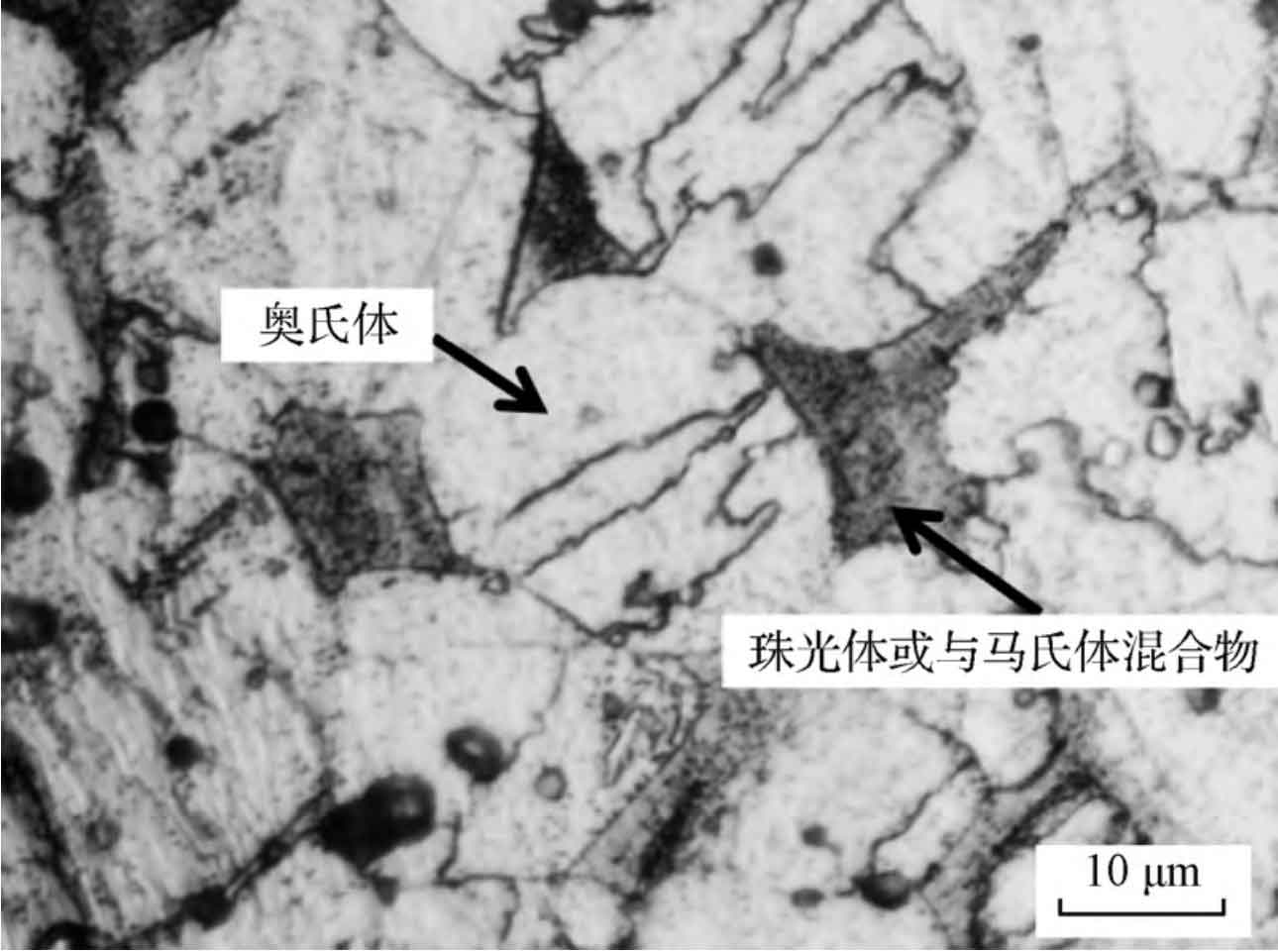

It can be seen from Table that the density and hardness of spur gear products have been close to the level of MIM17-4 PH stainless steel (theoretical density is 7.85 g/cm3, hardness is 270~300HV), especially the density, which has been close to the optimum density for sintering of general MIM products. Therefore, 1 300 ° C is selected as the temperature for optimization experiment. The metallographic microstructure of spur gear products is shown in Figure 2, which also conforms to the level of ordinary MIM sintered products.

| Project | Green density/(g · cm-3) | Sintered green density/(g · cm-3) | Vickers hardness HV (load 100 g) |

| Pilot experiment | 5.361~5.393 | 7.777~7.796 | 271.60~288.68 |

| Optimization experiment | 5.375~5.391 | 7.785~7.798 | 273.10~286.89 |

2. Dimension measurement and accuracy

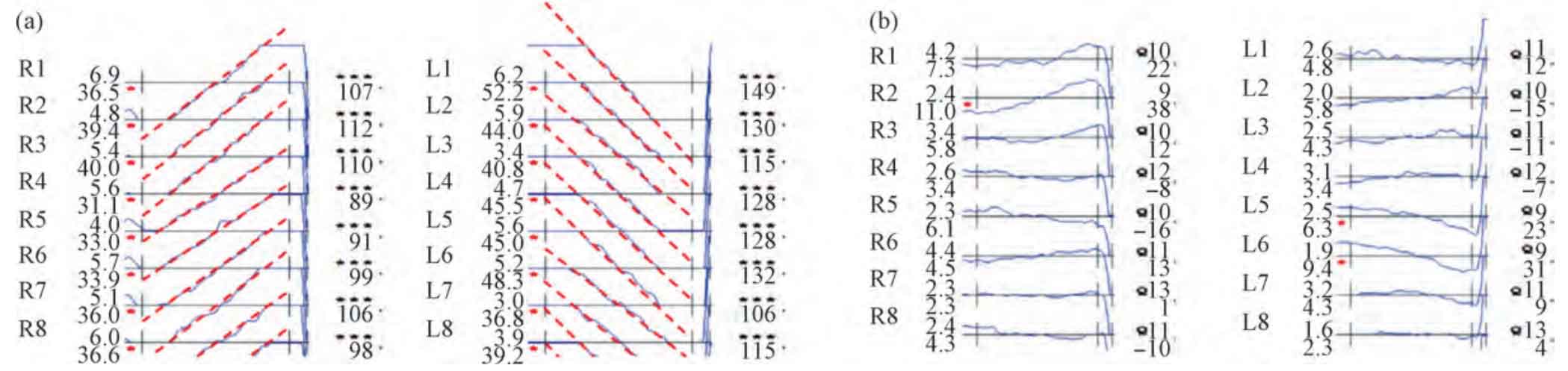

The dimension of spur gear products (without avoiding human measurement error) adopts automatic measurement method. The full-automatic spur gear measuring instrument can quickly measure some important dimensions of spur gear, and automatically determine the accuracy grade of the spur gear, reduce the error of human measurement, and improve the measurement efficiency. Figure 3 shows the comparison of the measured values of the precision of the straight gear of the MIM products before and after the mold repair of the straight gear mould by the automatic straight gear measuring instrument.

(b) The dimension after mold repair and compensation has met the specification, which is greater than AGMA Q9 grade.