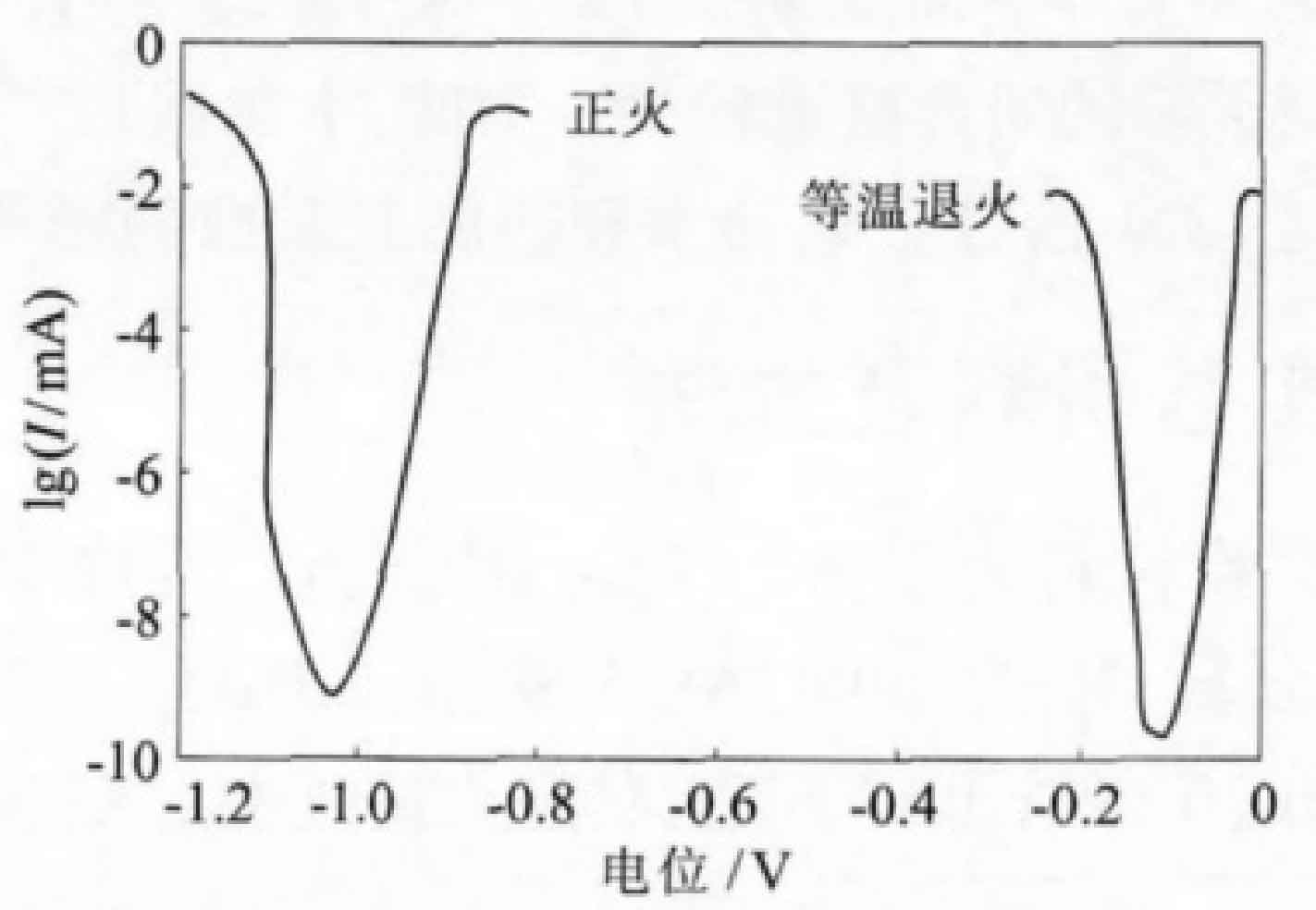

At 25 ℃ and 0.001 V / s scanning speed, the Tafel curve of automobile gear test material 20mncr5 steel after normalizing and isothermal annealing is shown in the figure. It can be seen from the figure that the corrosion potential of the material after normalizing treatment in 0.6mol/l NaCl solution is -1.032 V, while the corrosion potential of the material after isothermal annealing treatment is -0.115 v. Compared with normalizing treatment, isothermal annealing treatment makes the corrosion potential of the material move forward.

As we all know, the more positive the corrosion potential of the material, the stronger the corrosion resistance of the material. Therefore, isothermal annealing treatment is more conducive to the corrosion resistance of automobile gears in NaCl solution than normalizing treatment. This is consistent with the results of salt spray corrosion test and full immersion corrosion test.

The corrosion of automobile gears is a complex process, and a common pitting corrosion occurs in salt spray corrosion. The anti-corrosion performance of gears is related to the reliability and safety of the whole vehicle, which needs to be paid high attention. Reasonable design of heat treatment process is one of the effective ways to improve the corrosion resistance of automobile gears.

At present, China’s domestic enterprises still generally adopt normalizing process in the pre heat treatment of automobile gears, while foreign enterprises generally adopt isothermal annealing process. From the perspective of corrosion resistance, the pre heat treatment of automotive gears and the pre heat treatment process of isothermal annealing are much better than normalizing treatment. Isothermal annealing process should be used as much as possible.