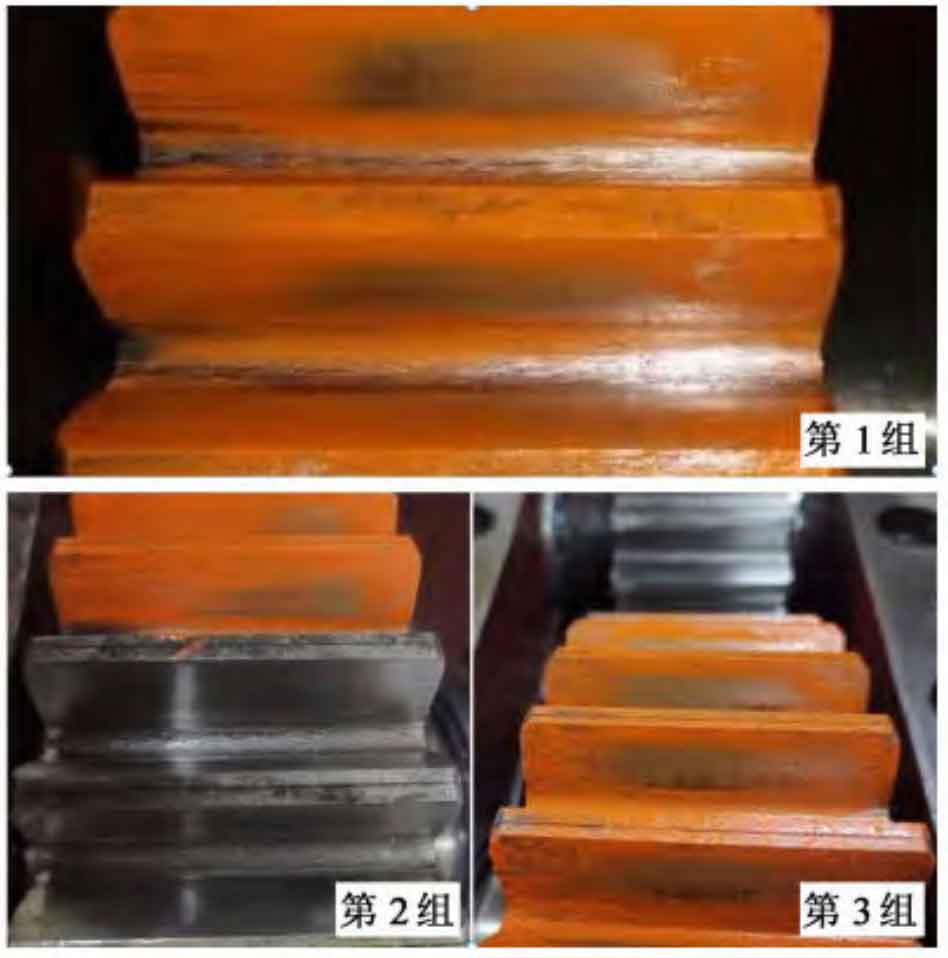

1. Contact spot inspection

The same test conditions were used for the three groups of tests. After the spur gear was installed, the contact quality of the tooth surface was inspected. Figure 1 shows the contact spots obtained from the rolling inspection of the three groups of test spur gear pairs. The contact pattern control of the first and third groups of spur gears is ideal, and the position of the second group of contact patterns is biased towards one end, which does not have a significant impact on vibration characteristics without edge contact.

2. Test conditions and steps

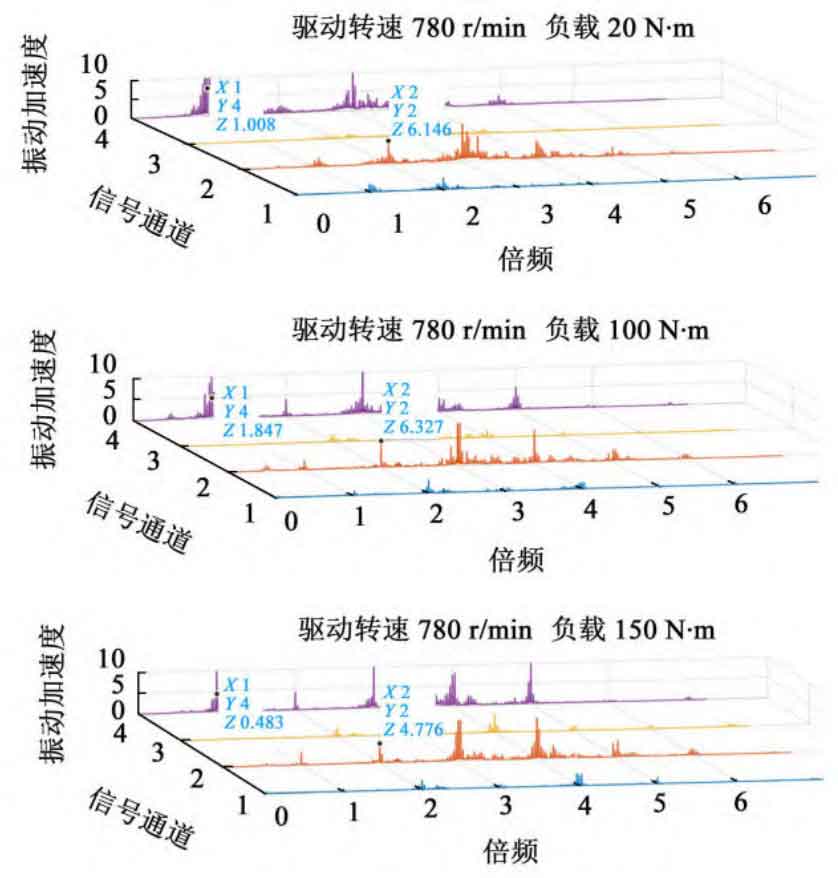

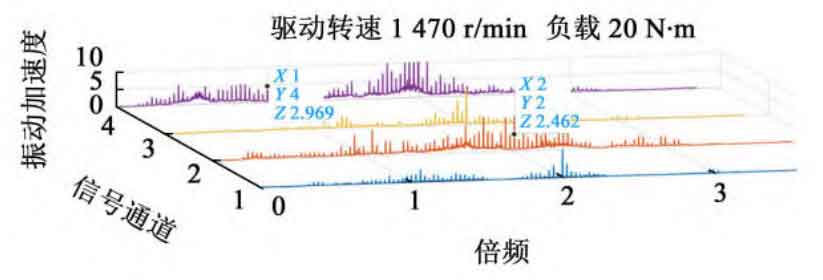

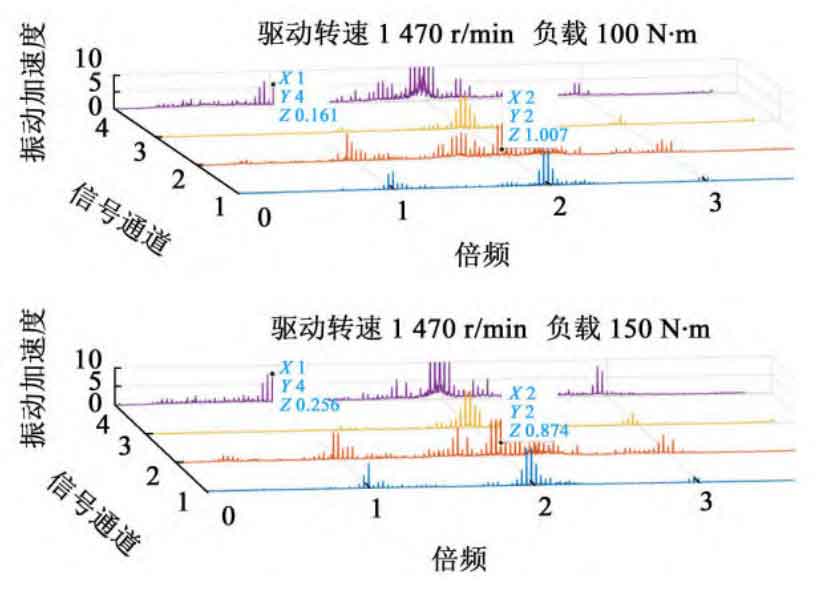

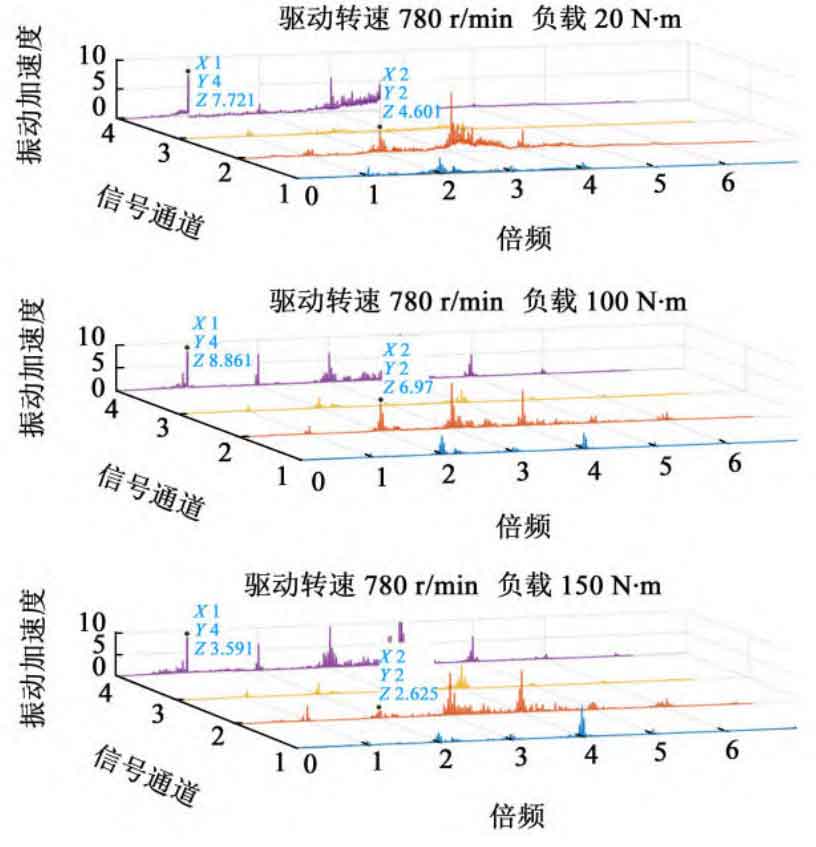

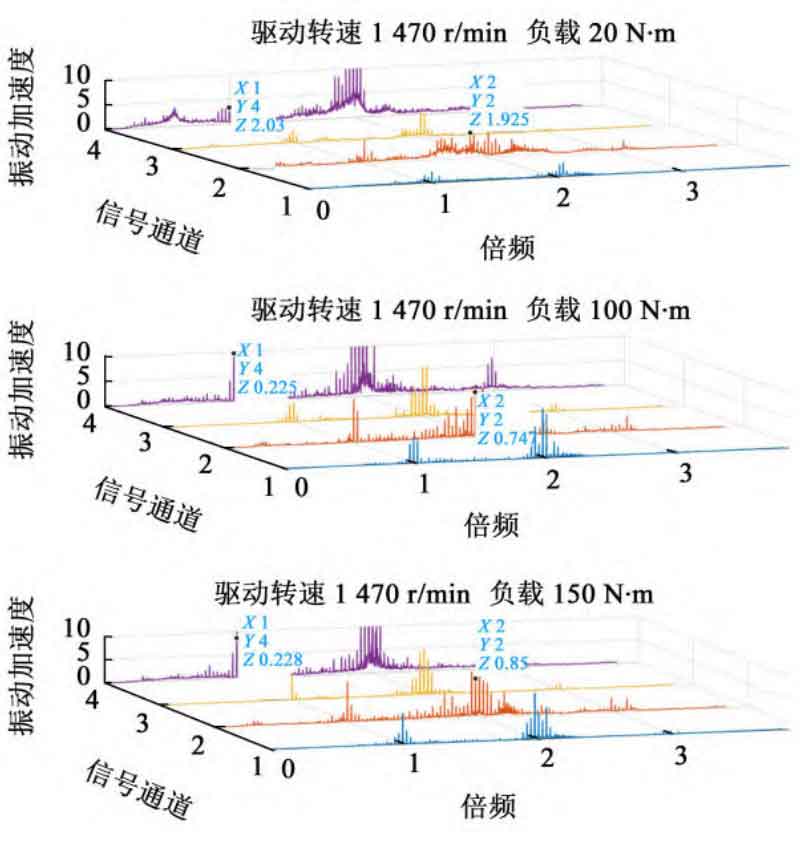

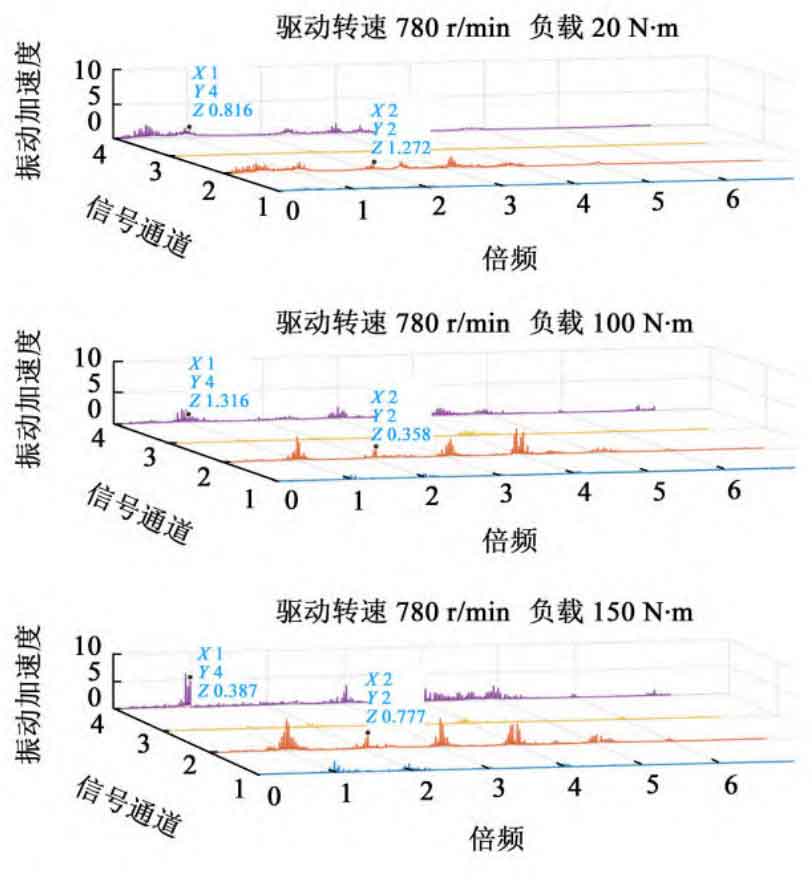

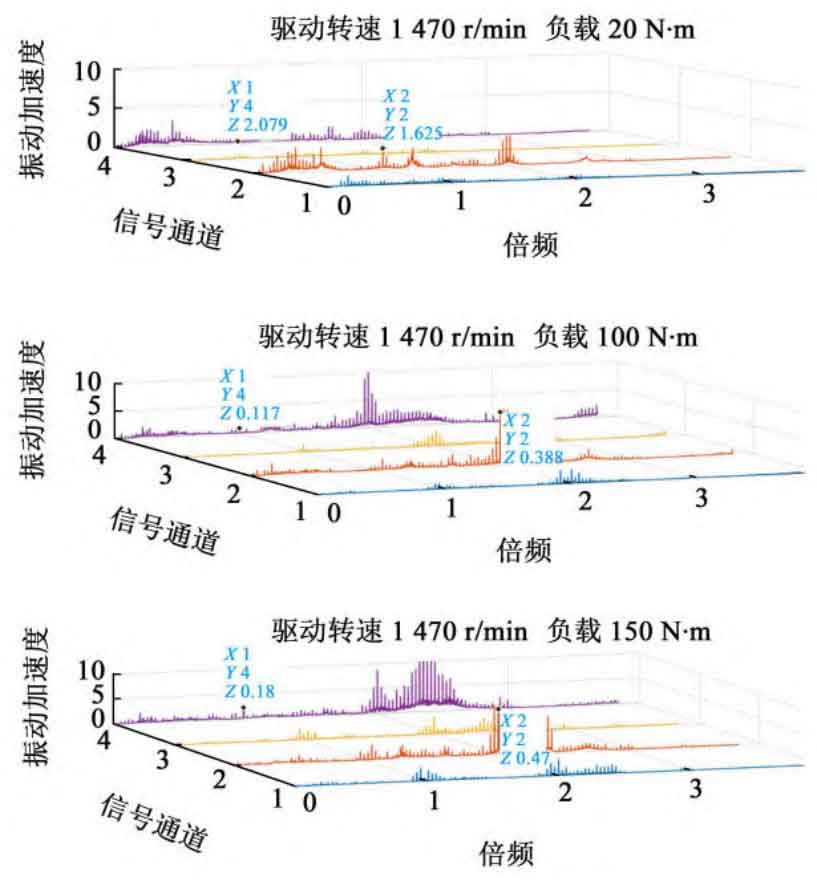

Three pairs of spur gears were tested for vibration performance at two speeds: 780 r/min, 1470 r/min, and three loads: 20 N · m, 100 N · m, and 150 N · m. The vibration spectrum analysis results are shown in Figures 2 to 7.