The parallel axis finishing process is used to carry out theoretical, simulation and experimental research on the finishing scheme of spiral bevel gear. The following conclusions are drawn:

(1) According to the mathematical model of finishing process, the cutting speed of abrasive is positively related to the workpiece radius, barrel speed and workpiece speed.

(2) In the initial stage of finishing of spiral bevel gear, the reduction rate of the small end roughness is greater than that of the large end, and the reduction rate of the concave surface roughness is greater than that of the convex surface.

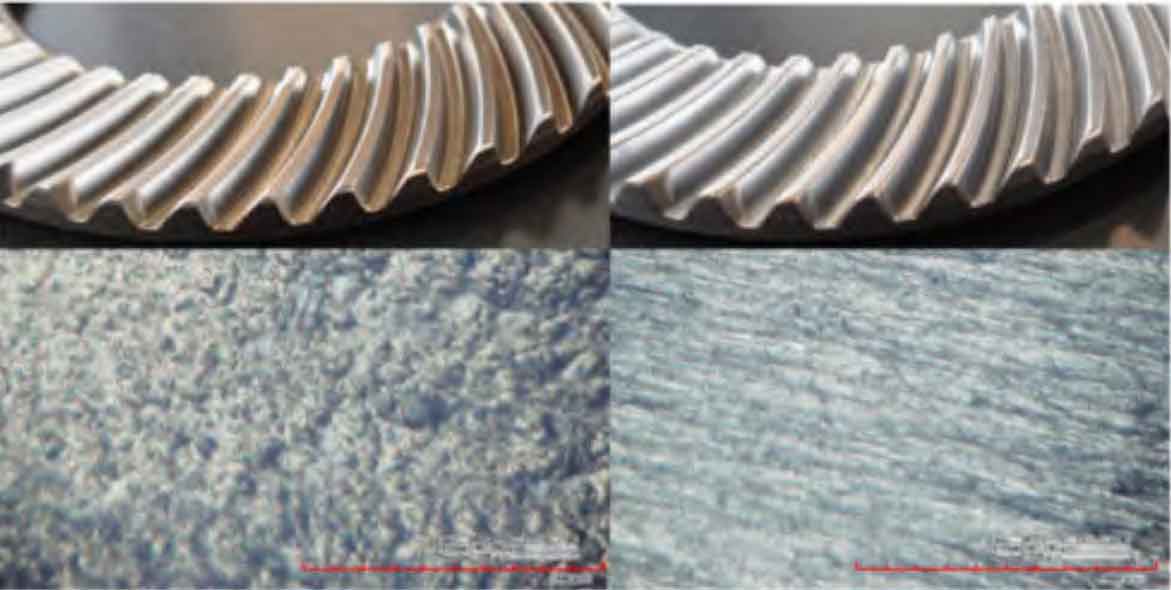

(3) The effectiveness of this technology in reducing the roughness of spiral bevel gears is verified by experiments, improving the surface quality of gears, reducing the meshing noise of gears and improving the service life of gears.