Helical gears are an essential component of many mechanical systems, offering several advantages over other gear types. Their unique design and characteristics make them suitable for various applications. In this comprehensive guide, we will explore the advantages of helical gears and their impact on gear systems.

- Improved Load Distribution: Helical gears have angled teeth that gradually engage, resulting in smoother and more uniform load distribution compared to spur gears. This feature reduces stress concentrations, minimizes noise and vibration, and increases the overall load-carrying capacity of the gears.

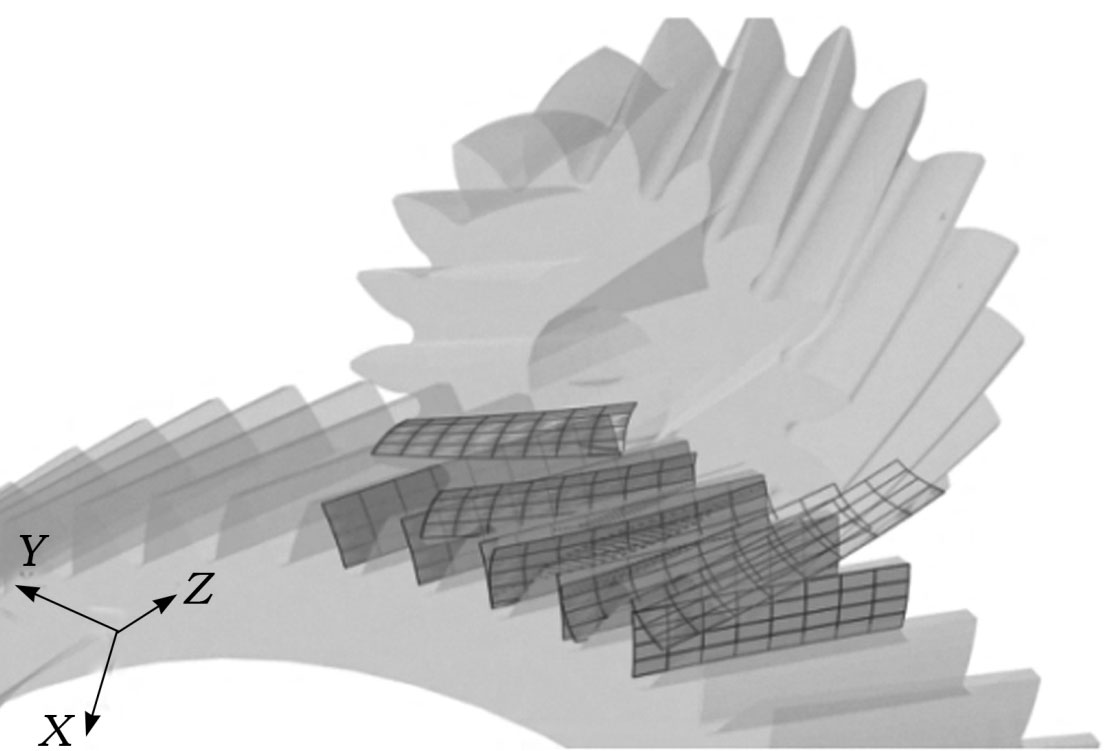

- Increased Contact Ratio: Helical gears provide a higher contact ratio, meaning multiple teeth are engaged simultaneously. This results in a larger contact area, improved torque transmission, and enhanced power distribution across the gear teeth. The increased contact ratio also helps to reduce wear and extends the gear’s lifespan.

- Quiet and Smooth Operation: Due to the gradual engagement of the teeth, helical gears operate with reduced noise and vibration levels. The angled teeth prevent sudden impacts and ensure a smooth transfer of power, making helical gears ideal for applications that require quiet operation, such as in automotive transmissions or industrial machinery.

- High Efficiency: Helical gears offer higher efficiency compared to some other gear types, such as worm gears. The angled teeth facilitate a more gradual meshing process, resulting in lower friction and reduced power loss. This efficiency is particularly advantageous in applications where energy conservation is a priority, such as in gearboxes or drivetrains.

- Versatility and Flexibility: Helical gears can be designed with various configurations, such as parallel shaft or crossed helical arrangements, to accommodate different space constraints and load requirements. They can also be combined with other gear types, such as bevel gears or worm gears, to create complex gear systems that suit specific applications.

- Superior Tooth Strength: The helical tooth profile provides excellent tooth strength and resistance to shear forces. This allows helical gears to handle higher loads and transmit greater torque compared to spur gears. The increased tooth strength also contributes to the overall durability and reliability of the gear system.

- Easy Maintenance and Replacement: Helical gears are relatively easy to maintain and replace. Their design allows for individual gear replacement without requiring the entire gear system to be dismantled. This ease of maintenance reduces downtime and enhances the overall efficiency of gear-driven machinery.

- Wide Range of Applications: Helical gears find applications in various industries, including automotive, aerospace, power generation, industrial machinery, and more. They are commonly used in gearboxes, transmissions, rotary equipment, and other systems that require efficient power transmission and torque conversion.

Understanding the advantages of helical gears enables engineers and designers to make informed decisions when selecting gears for their specific applications. By leveraging the benefits of helical gears, manufacturers can enhance the performance, reliability, and efficiency of their gear systems, contributing to improved overall machinery performance.