The shearer needs to work in the underground roadway of the coal mine, and its working environment is poor. An ec710 shearer is suitable for coal seam mining height of 0.85 ~ 1.60 m, maximum theoretical production capacity of 528 T / h, maximum traction force of 20 t and traction speed of 0 ~ 5.5 m / min. During the final inspection of the disc gear of the shearer, it was found that there were grinding cracks on the surface of the gear. The relevant units attached great importance to this, because the maintenance of the shearer under the mine is extremely difficult, which will cause serious economic losses. In order to take corresponding remedial measures, the corresponding failure analysis of this batch of gears was carried out.

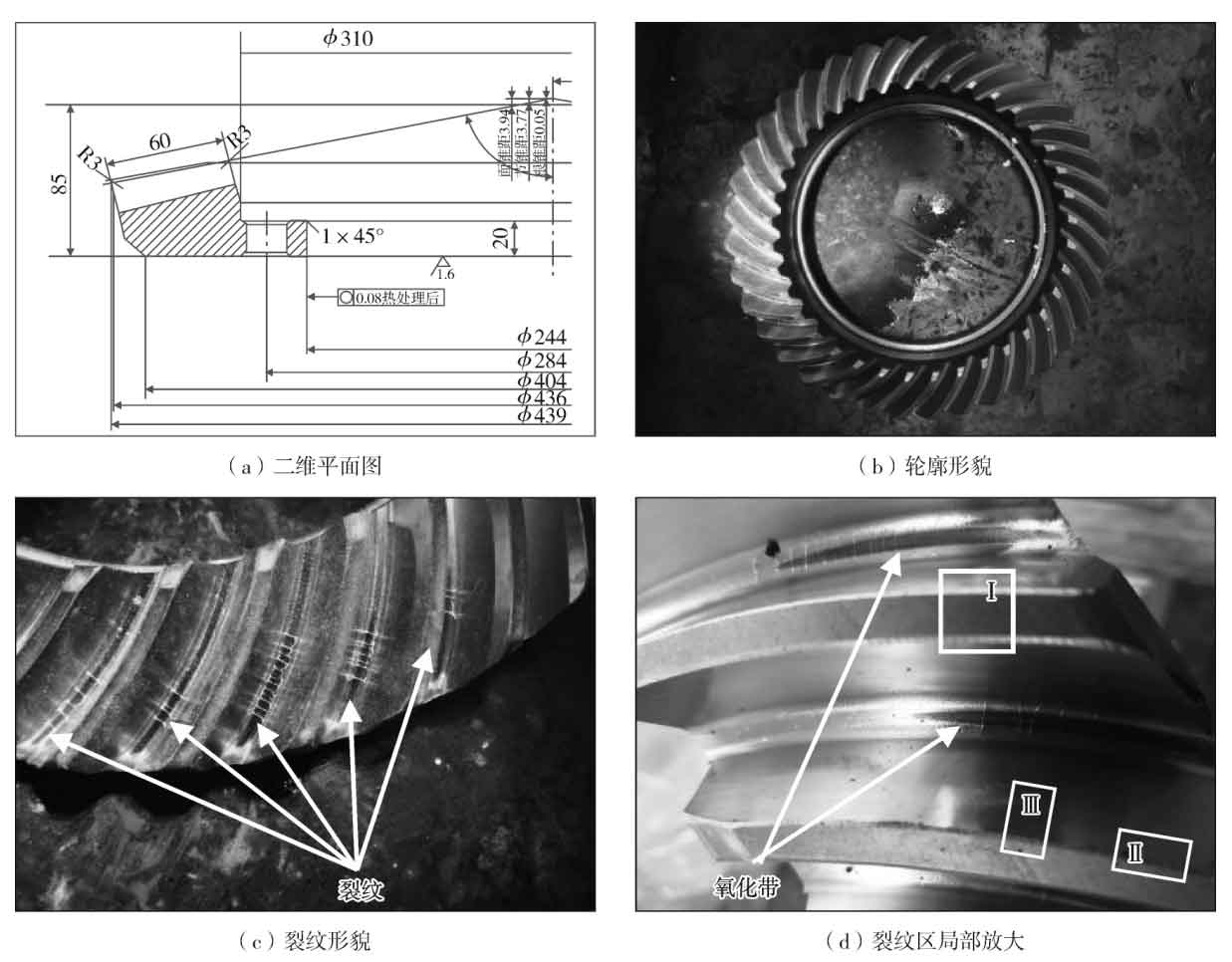

The two-dimensional plan of the shearer gear is shown in figure a, and the maximum diameter of the gear Φ 439 mm, modulus 10.20, average pressure angle 22 ° 30 ‘, speed ratio 5.96. Gear machining process: blanking → forging → quenching and tempering → rough turning → semi-finished turning → gear hobbing → chamfering → carburizing → quenching + low temperature tempering → gear grinding → cleaning → enhanced shot peening → cleaning → finished product inspection and warehousing. The material used for the gear is 25CrMo steel, the forging temperature is 850 ~ 1150 ℃, the quenching and tempering temperatures of quenching and tempering are 890 ℃ and 540 ℃ respectively, carburizing and oil cooling quenching at 920 ℃, then low temperature tempering at 200 ℃ and strong shot peening. The hardness of the steel shot is 55 ~ 60 HRC, and the diameter of the steel shot is about Φ 0.8 mm, 150% coverage. The profile of the gear is in a flat disk shape, as shown in Figure B. the hcdg-6000 special fluorescent magnetic particle flaw detector for outer gear ring is used for magnetic particle flaw detection of this batch of gears. The longitudinal current of the flaw detector is 1800 a and the transverse current is 420 a. the flaw detection method is carried out in accordance with GB / T 15822.1-2005 “nondestructive testing, magnetic particle testing, Part 1: general”. There are 32 gears in this batch. After selection, 10 gears have grinding cracks. Fig. C is a photo of grinding crack in fluorescent magnetic particle flaw detection. The grinding crack is at the root between two teeth, with a length of about 4 ~ 8 mm. The grinding cracks are approximately parallel to each other and perpendicular to the grinding direction. Figure D is an enlarged view of grinding cracks between two teeth. It can be seen from the figure that there are black oxidation zones along the grinding direction at the location of grinding cracks between two teeth, and grinding cracks occur in the areas with black oxidation zones. Therefore, it can be inferred that there may be a certain relationship between oxidation zones and the generation of grinding cracks, which should be analyzed emphatically.