Shearer gears operate under extreme conditions in underground coal mining. During final inspection of disk-shaped gears for an EC710 shearer (rated capacity: 528 t/h), surface grinding cracks were detected. Given the severe economic impact of in-mine repairs, comprehensive failure analysis was performed on the affected batch.

Failure Background

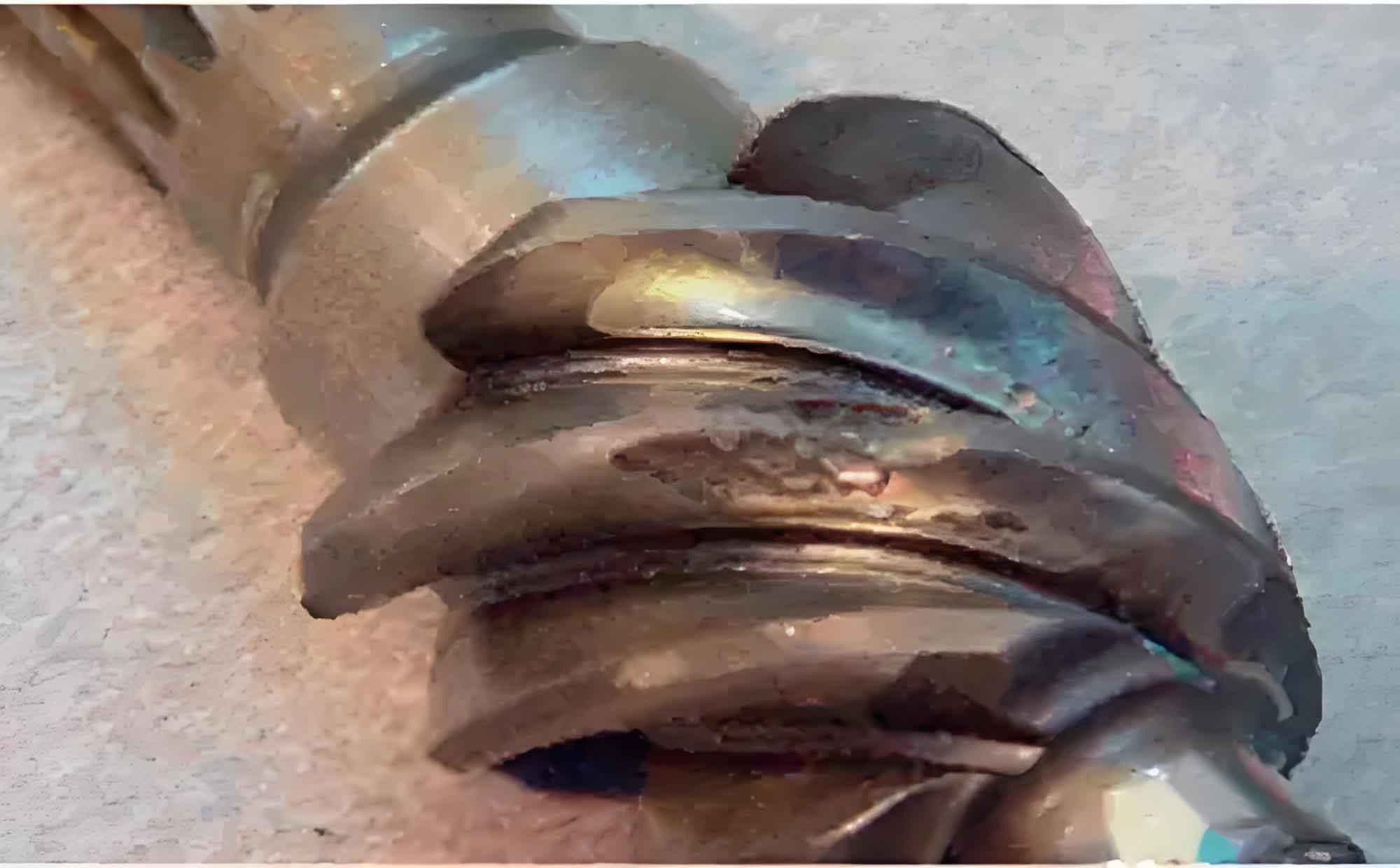

Cracks measuring 4–8 mm appeared at tooth roots after magnetic particle inspection (GB/T 15822.1-2005). Key observations:

- Parallel cracking perpendicular to grinding direction

- Black oxidation zones co-located with grinding cracks

- Macroscopic characteristics suggesting thermal origin

Manufacturing process sequence: Forging → Normalizing → Rough machining → Carburizing (920°C) → Quenching → Low-temp tempering (200°C) → Grinding → Shot peening.

Material Composition Examination

Chemical analysis (GB/T 4336-2002) of 25CrMo steel:

| Element | Surface (wt%) | Core (wt%) | Standard (GB/T 3077-2015) |

|---|---|---|---|

| C | 1.03 | 0.27 | 0.22–0.29 (core) |

| Cr | 1.16 | 1.14 | 0.90–1.20 |

| Mn | 0.85 | 0.86 | 0.60–0.90 |

| Mo | 0.24 | 0.21 | 0.15–0.30 |

| Si | 0.35 | 0.32 | 0.17–0.37 |

Compliance confirmed with no segregation detected.

Microstructural Examination

Microstructure analysis (GB/T 13298-2015, GB/T 25744-2010):

| Location | Microstructure | Rating |

|---|---|---|

| Normal zone (surface) | Martensite + retained austenite | Grade 2 |

| Normal zone (core) | Low-carbon martensite + free ferrite | Grade 3 |

| Oxidized zone (surface) | Tempered troostite + spheroidized carbides | N/A |

Critical observations in grinding crack zones:

- Microstructural evidence of tempering (carbide precipitation)

- Crack propagation morphology: Y-shaped branching (depth: 1.68 mm)

- Thermal influence limited to surface layers

Hardness Gradient Analysis

Vickers hardness profiles (GB/T 9450-2005, load: 9.8 N):

Effective case depth calculation:

$$ \text{CHD} = d_{550 \text{HV}} $$

where \(d_{550 \text{HV}}\) is depth where hardness reaches 550 HV.

| Zone | Surface Hardness (HV) | Effective Case Depth (mm) | Core Hardness (HV) |

|---|---|---|---|

| Normal | 698 | 2.30 | 380 |

| Oxidized | 450 | 2.20 | 375 |

Hardness anomaly in oxidized zones:

$$ \Delta H = H_{\text{normal}} – H_{\text{oxidized}} = 248 \text{ HV} $$

indicating significant thermal softening.

Thermo-Mechanical Analysis of Grinding Cracks

Grinding cracks originated through synergistic mechanisms:

1. Thermal Shock Stress:

$$ \sigma_{\text{thermal}} = E \alpha \Delta T $$

where \(E\) = Young’s modulus (210 GPa), \(\alpha\) = thermal expansion coefficient (12.5 × 10⁻⁶/°C), \(\Delta T\) ≈ 600°C (estimated).

2. Phase Transformation Stress:

$$ \Delta V = \left( \frac{V_{\gamma} – V_{\alpha’}}{V_{\gamma}} \right) \approx 4\% $$

Austenite (γ) to martensite (α’) transformation during requenching generates tensile stress.

3. Residual Stress Superposition:

$$ \sigma_{\text{total}} = \sigma_{\text{thermal}} + \sigma_{\text{phase}} + \sigma_{\text{residual}} $$

When \(\sigma_{\text{total}} > \sigma_{\text{UTS}}\) (material ultimate tensile strength), grinding cracks initiate.

Root Cause Identification

Primary factors inducing grinding cracks:

- Excessive grinding heat generation:

- Temperature > Ac1 (≈750°C)

- Localized austenitization

- Insufficient cooling:

$$ \dot{q}_{\text{cooling}} < \dot{q}_{\text{generation}} $$ - Original grinding parameters:

- Depth of cut: 0.08 mm/pass

- Al2O3 grinding wheel (high friability)

Corrective Measures and Validation

Implemented solutions for grinding crack mitigation:

| Parameter | Original | Optimized | Effect |

|---|---|---|---|

| Abrasive type | Brown alumina | White alumina | ↓ Heat generation by 35% |

| Depth of cut | 0.08 mm/pass | 0.04 mm/pass | ↓ Grinding force by 50% |

| Stress relief | None | 160°C × 72h | ↓ Residual stress by 40% |

Validation results after optimization:

- 0 grinding cracks in subsequent 150 gear batches

- Surface hardness consistency: ΔHV < 30

- Microstructural uniformity confirmed

Conclusions

- Grinding cracks exhibited perpendicular orientation to grinding direction with associated oxidation zones

- Thermal softening in affected regions (ΔHV ≈ 250) confirmed microstructural degradation

- The fundamental mechanism involves combined thermal and transformation stresses:

$$ \sigma_{\text{total}} = E \alpha \Delta T + K \Delta V + \sigma_R $$ - Process optimization successfully eliminated grinding cracks through:

- Abrasive system modification

- Reduced grinding aggression

- Pre-grinding stress relief

This systematic approach provides a general framework for preventing grinding cracks in high-performance gears subjected to abusive machining conditions.